25-hydroxyvitamin D3 microcapsule powder and preparation method thereof

A technology of hydroxyvitamin and microencapsulated powder, which is applied in the field of feed additives, can solve problems such as instability and impact, and achieve the effect of improving utilization efficiency and embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

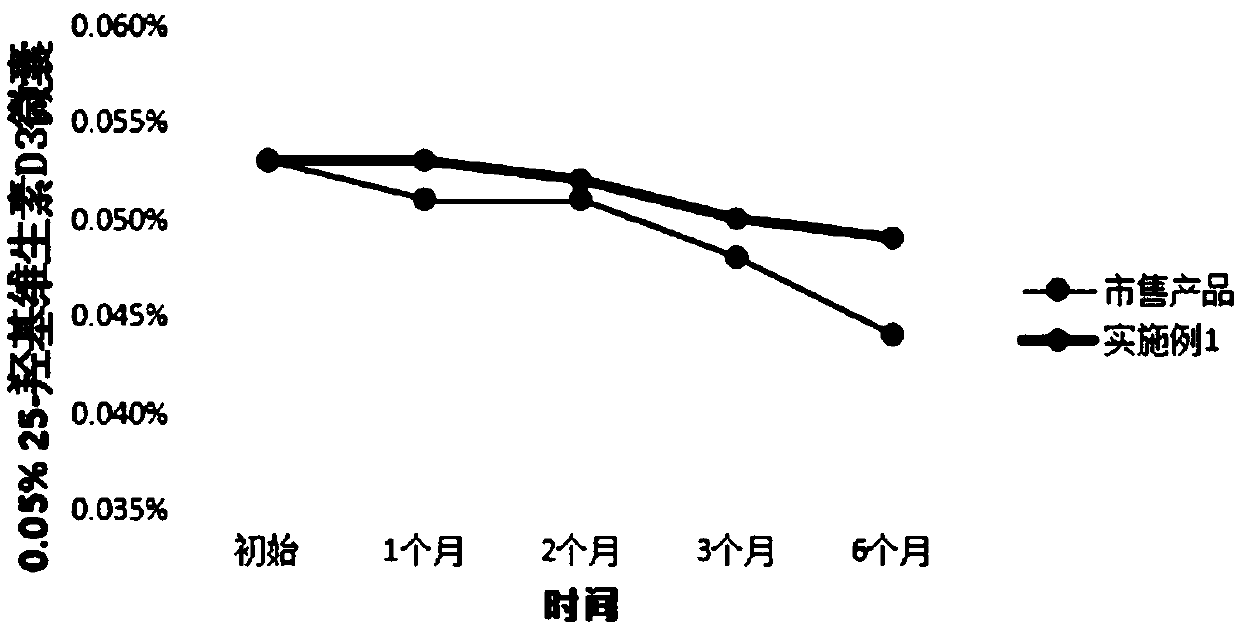

Embodiment 1

[0061] The 25-hydroxyvitamin D of this embodiment 3 The preparation method of microcapsule powder comprises the following steps:

[0062] 1. Prepare materials

[0063] 25-Hydroxyvitamin D 3 : 0.05 parts

[0064] Butylated hydroxytoluene (BHT): 1 part

[0065] Octenyl succinic esterified starch HI-CAP100: 35 parts

[0066] Sodium carboxymethylcellulose HL7: 2.5 parts

[0067] Gelatin: 5 parts

[0068] Maltodextrin 10: 49.45 parts

[0070] Sodium acetate: 1 part

[0071] Tween 80: 1 serving

[0072] Distilled water: 125 parts

[0073] 2. Preparation of the first reaction solution

[0074] Add Tween 80 and butylated hydroxytoluene (BHT) into the oil barrel, place the oil barrel in a hot water tank (3 , stirred and emulsified for 20 to 30 minutes to generate the first reaction solution.

[0075] 3. Preparation of the second reaction solution

[0076] Add distilled water to the emulsification tank, add sucrose when heated to 50℃~55℃, stir for...

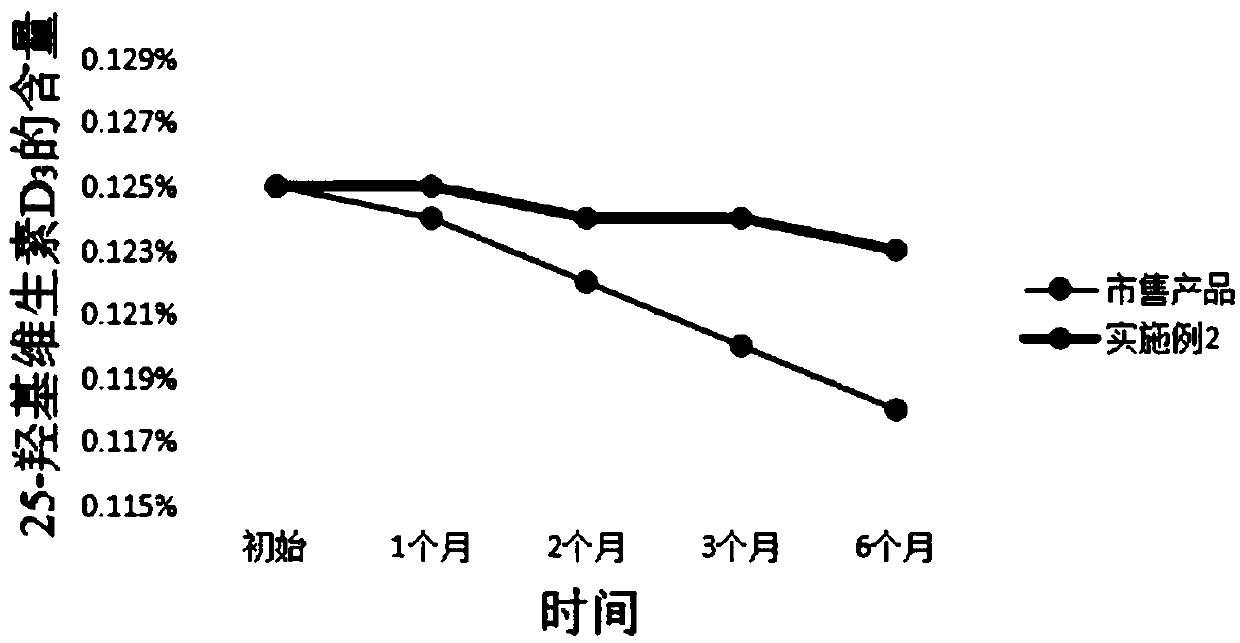

Embodiment 2

[0105] The 25-hydroxyvitamin D of this embodiment 3 The preparation method of microcapsule powder comprises the following steps:

[0106] 1. Prepare materials

[0107] 25-Hydroxyvitamin D 3 : 0.125 parts

[0108] Butylated hydroxytoluene (BHT): 1.5 parts

[0109] Octenyl succinic esterified starch HI-CAP100: 32.875 parts

[0110] Sodium carboxymethylcellulose HL7: 3 parts

[0111] Gelatin: 6 parts

[0112] Maltodextrin 10:48 parts

[0113] Sucrose: 5.5 parts

[0114] Sodium acetate: 1.5 parts

[0115] Tween 80: 1.5 servings

[0116] Distilled water: 145 parts

[0117] 2. Preparation of the first reaction solution

[0118] Add Tween 80 and butylated hydroxytoluene (BHT) into the oil barrel, place the oil barrel in a hot water tank (3 , stirred and emulsified for 20 to 30 minutes to generate the first reaction solution.

[0119] 3. Preparation of the second reaction solution

[0120] Add distilled water to the emulsification tank, add sucrose when heated to 50℃~55℃,...

Embodiment 3

[0133] The 25-hydroxyvitamin D of this embodiment 3 The preparation method of microcapsule powder comprises the following steps:

[0134] 1. Prepare materials

[0135] 25-Hydroxyvitamin D 3 : 0.25 parts

[0136] Butylated hydroxytoluene (BHT): 2 parts

[0137] Octenyl succinic esterified starch HI-CAP100: 32.75 parts

[0138] Sodium carboxymethylcellulose HL7: 3.5 parts

[0139] Gelatin: 6.5 parts

[0140] Maltodextrin 10:46 parts

[0142] Sodium acetate: 2 parts

[0143] Tween 80: 2 servings

[0144] Distilled water: 145 parts

[0145] 2. Preparation of the first reaction solution

[0146] Add Tween 80 and butylated hydroxytoluene (BHT) into the oil barrel, place the oil barrel in a hot water tank (3 , stirred and emulsified for 20 to 30 minutes to generate the first reaction solution.

[0147] 3. Preparation of the second reaction solution

[0148] Add distilled water to the emulsification tank, add sucrose when heated to 50°C~55°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com