Automatic thermal desorption instrument based on thermal gas desorption

A hot gas and thermal desorption technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., to achieve the effect of increasing the desorption rate, improving the desorption effect, and improving the desorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

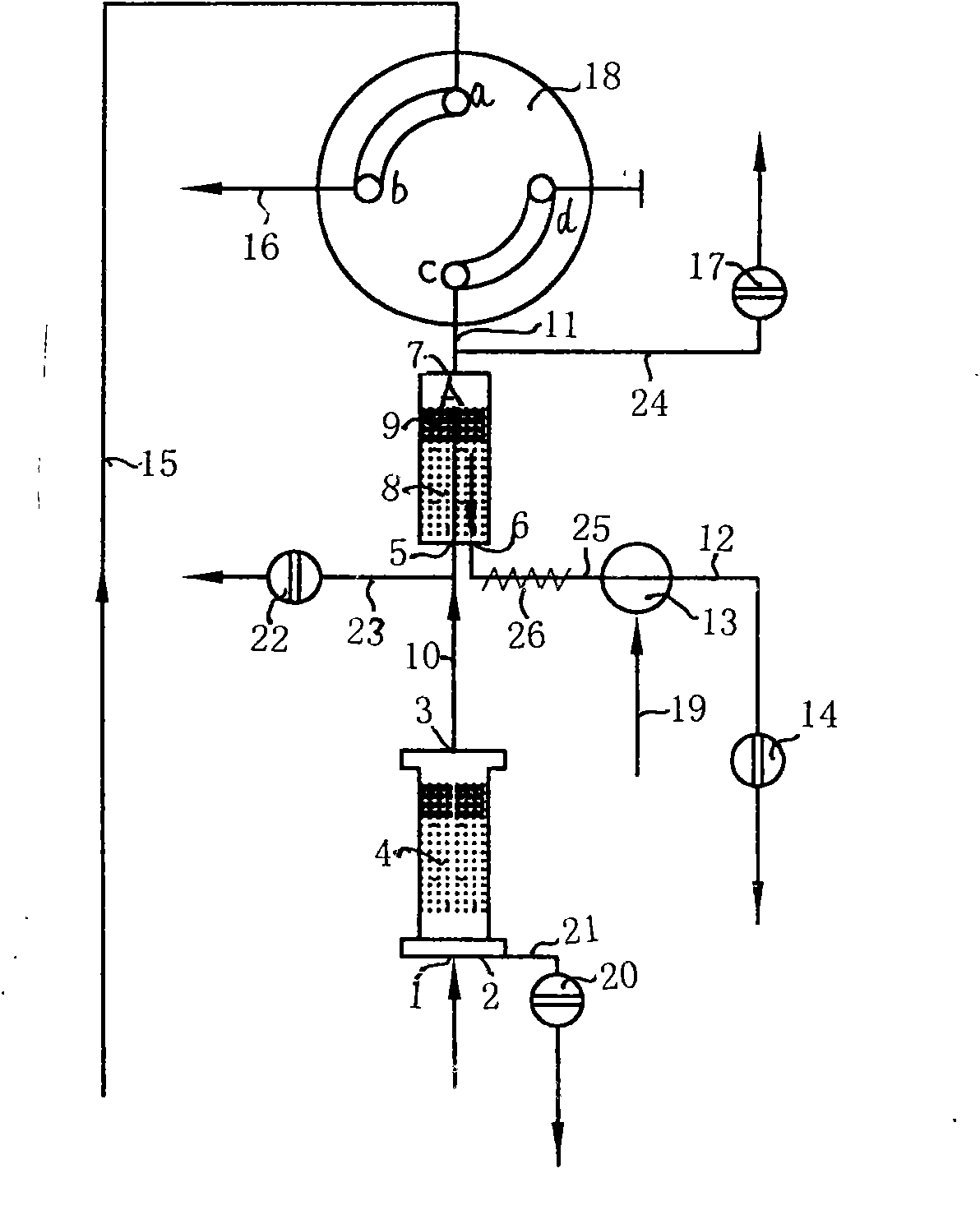

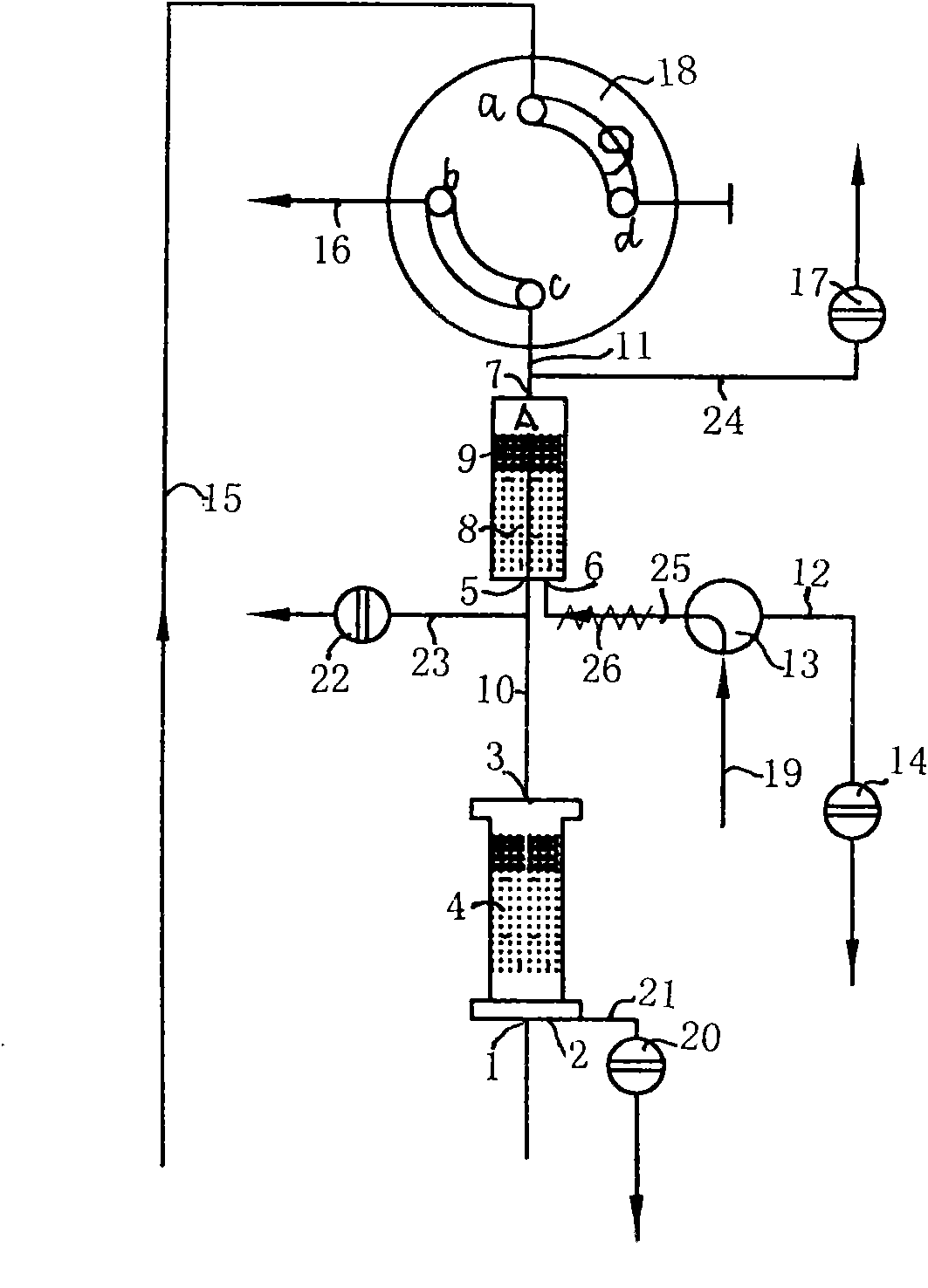

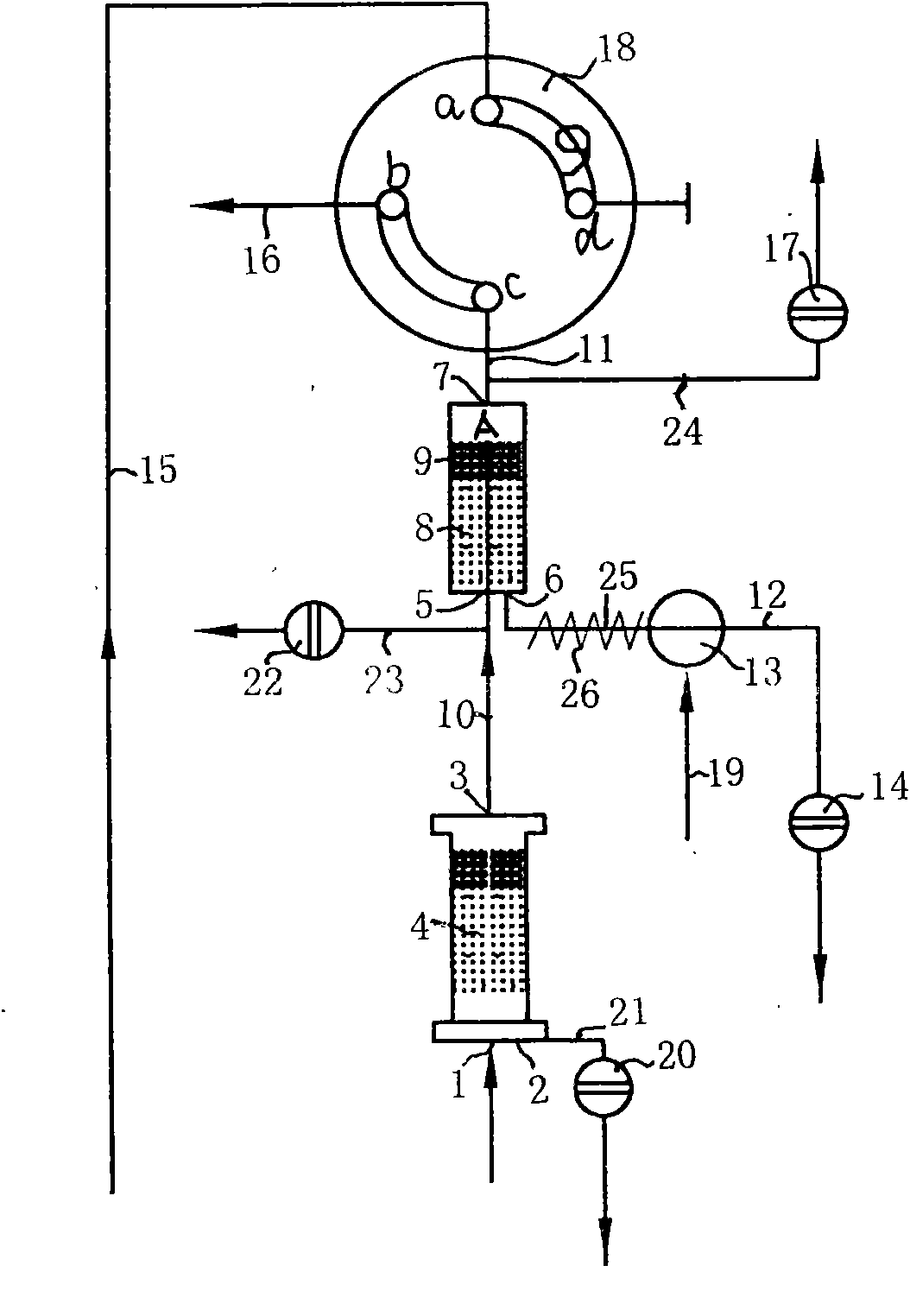

[0015] see figure 1 , the present embodiment adopts the automatic thermal desorption desorption instrument of hot gas desorption, comprises the sample tube 4 that sample and adsorbent are equipped with carrier gas input port 1 and first desorption sample outlet 3, is positioned at the top of sample tube with desorption sample Inlet 5, adsorption and desorption inlet and outlet 6, and second desorption sample outlet 7 are equipped with condensation adsorption tube 9 with adsorbent 8. The first end of the first sample output pipe 10 communicates with the first desorption sample outlet on the sample tube, and the second end passes through the desorption sample inlet and the adsorbent on the condensation adsorption tube and extends out of the end surface A of the adsorbent. The first end of the second sample output pipe 11 communicates with the second desorption sample outlet on the condensation adsorption pipe. A heater 26 is installed on the preheated carrier gas delivery pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com