Process for extracting C4-C6 normal paraffins and coproducing isopentane and heterogeneous hexane cooperatively produced from light naphtha

A technology for n-alkane and light naphtha, which is applied in the petroleum industry, hydrocarbon oil treatment, adsorption purification/separation, etc. The effect of high separation, reduced energy consumption, and accelerated desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0025] Implementation Case 1: A petrochemical enterprise hydrocracked light naphtha as raw material, and the main composition of light naphtha is shown in Table 1:

[0026] Table 1 Composition of Light Naphtha

[0027]

[0028]

[0029] Table 2 shows the time distribution of the PSA cycles in the four towers: one PSA cycle is 24 minutes, and the specific time distribution for each stage is shown in Table 2.

[0030] Table 2 Four-tower pressure swing adsorption cycle schedule

[0031]

[0032] [Note]: A-adsorption, ED-average pressure drop, R-displacement, V-desorption, ER-average pressure rise, H-regeneration

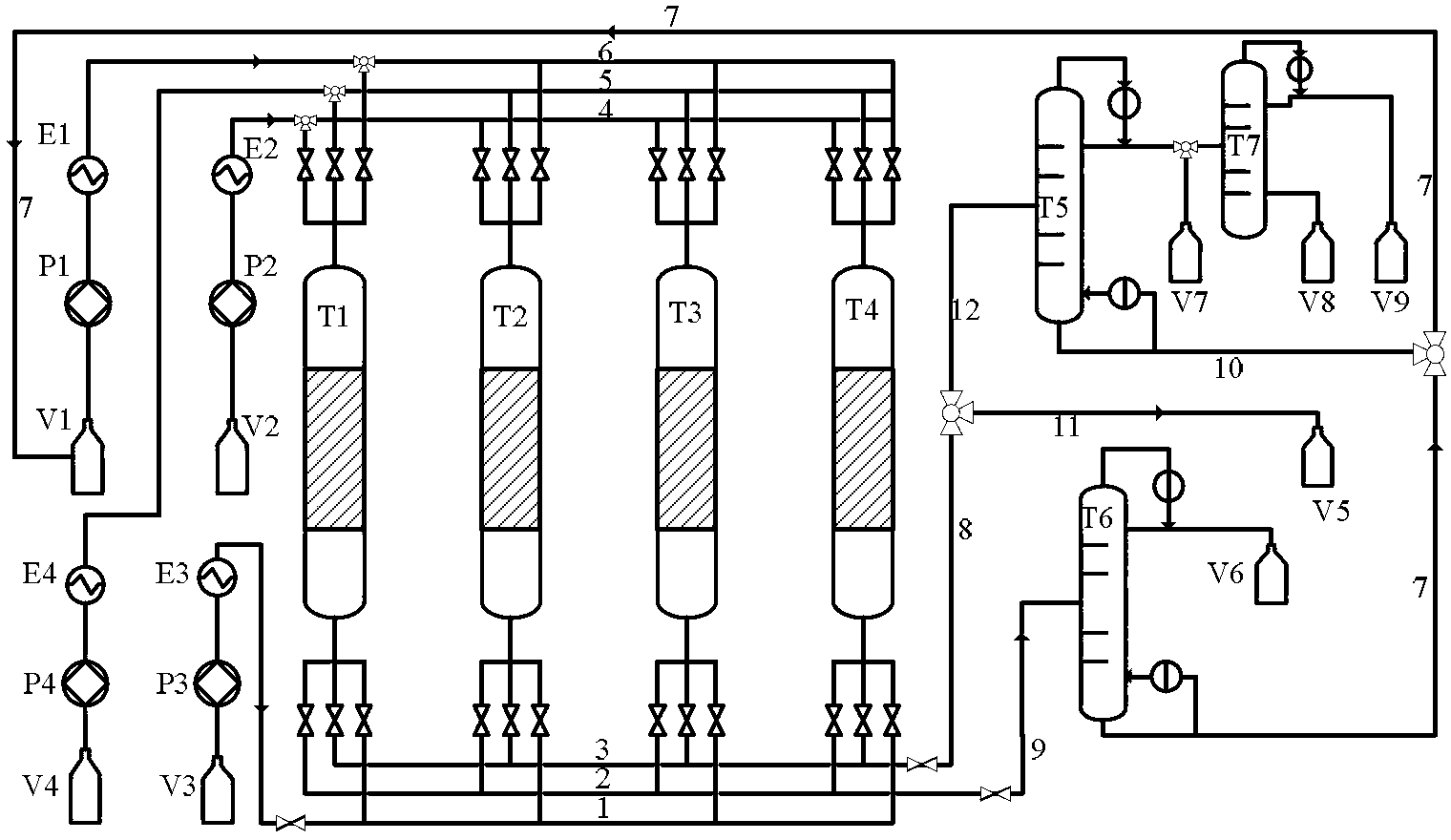

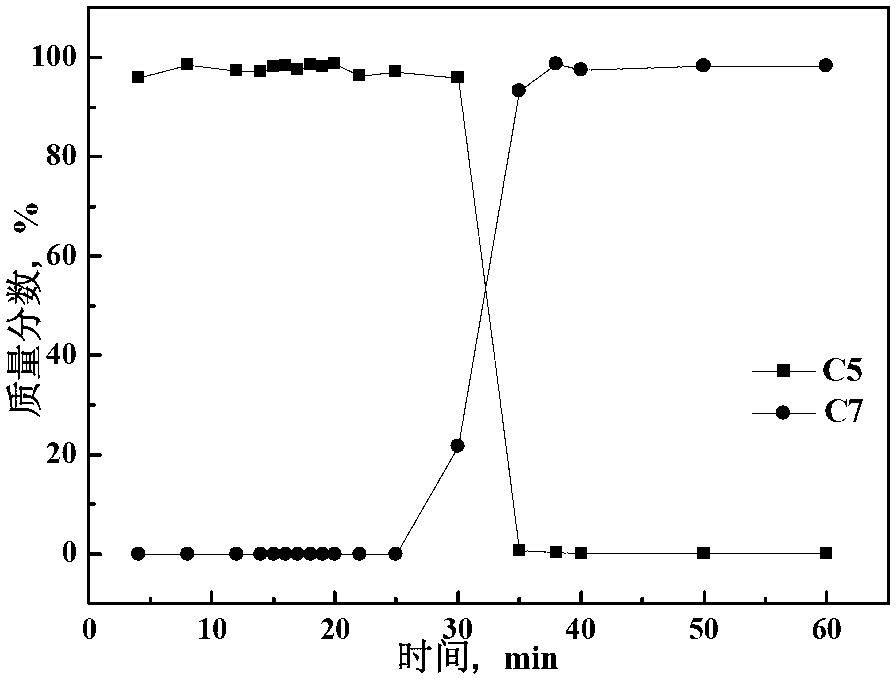

[0033] Separation of normal paraffins in light naphtha based on pressure swing adsorption process figure 1 , Adsorption: V3 storage tank light naphtha raw material, through the advection pump P3 into the vaporization chamber E3, gasification at 150 ℃ and 0.4MPa (gauge pressure), the gasified light naphtha enters T1 through pipeline 1; Pressure drop, after th...

Embodiment example 2

[0039] Implementation case 2: Separation of catalytic cracking naphtha in a petrochemical enterprise. Process flow is similar to example 1.

[0040] The adsorption temperature is 450°C, the adsorption pressure is 3MPa (gauge pressure), the desorption temperature is 450°C, the desorption pressure is 1MPa (gauge pressure), and the desorption space velocity is 2000h -1 , the regeneration temperature is 450°C, the regeneration pressure is 2MPa (gauge pressure), the regeneration space velocity is 2000h-1, the desorbent is a mixed component of n-heptane and n-hexane, and after the desorption is completed, C4-C6 isomeric alkanes are used to desorb the bed regeneration. The number of effective plates of the rectification towers T5, T6 and T7 is 120, 120 and 150 respectively, and the final product purity is shown in Table 4.

[0041] The purity of each component after table 4 rectification

[0042]

Embodiment example 3

[0043] Implementation case 3: Using a factory reformed topping oil as raw material, the composition of the raw material is shown in Table 5.

[0044] Table 5 Composition of reformed top oil

[0045]

[0046]

[0047] The four-tower pressure swing adsorption separation process is still used, and the adsorption process is similar. During desorption, n-octane with stronger adsorption force is used as the desorption agent, and the desorption rate and desorption effect of the gas phase and the liquid phase are compared. Bed regeneration uses isopentane as regenerant.

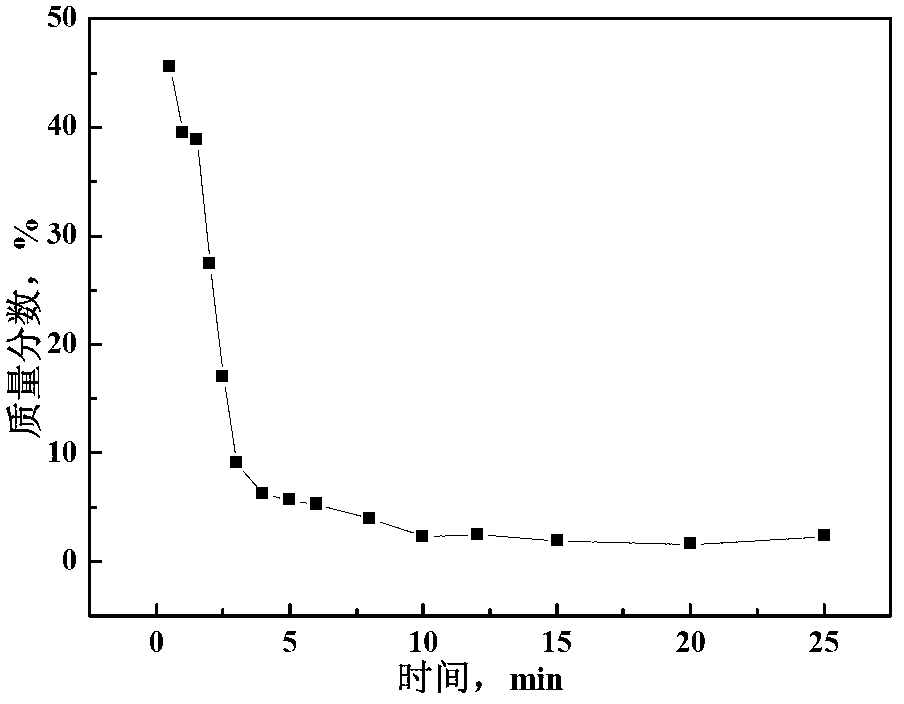

[0048] When the desorbent with the same liquid phase flow rate is used for desorption, the gas phase desorption after gasification and the direct liquid phase desorption rate are compared for example Figure 4 shown, from Figure 4 It can be seen that the gas phase desorption rate is significantly greater than the liquid phase desorption rate, and the maximum desorption rate is reached within 5 minutes, while...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com