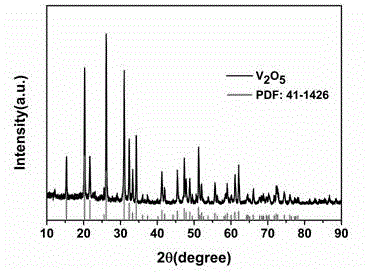

Porous V2O5/C composite microspheres of lithium secondary battery positive electrode material and preparation method of porous V2O5/C composite microspheres

A lithium secondary battery and positive electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficult to control product structure, unknown improvement of cycle performance, complex synthesis process, etc., to achieve optimal physical and electrochemical Performance, improved electrode process kinetics, effect of increased Li+ diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

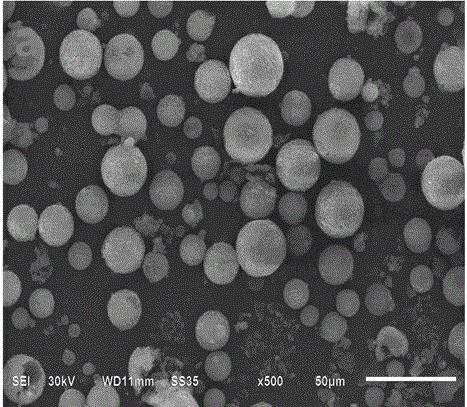

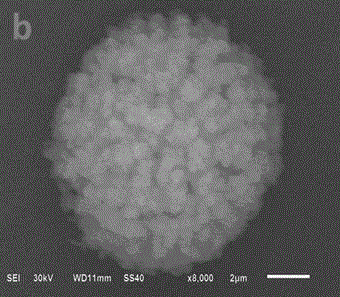

[0040] The present invention will be further described in detail with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0041] (1) Preparation of PMMA microsphere template. In a three-neck flask containing 125 ml of deionized water, add 0.01 g of sodium dodecylsulfonate (SDS), 1.7496 g of methyl methacrylate (MMA) and 0.0933 g of N,N '-Methylenebisacrylamide (MBA), after mechanically stirring evenly, slowly add 5 mL of a solution containing 0.14 g of potassium persulfate (KPS). After purging oxygen with nitrogen for 1 h, raise the temperature of the reaction system to 65-75 °C, and condense and reflux for 2-3 h under the protection of nitrogen to obtain a milky white mixture. After filtration, the powder was washed with water and ethanol 2 to 3 times to obtain cross-linked PMMA microgel spheres. Finally, the PMMA microspheres were reacted in 0.5 mol / L lithium hydroxide solution for 0.5 h, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com