Preparation method of flake copper powder

A technology of flake copper powder and flake, which is applied in the field of preparation of metal powder materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of flake copper powder, the specific steps are as follows:

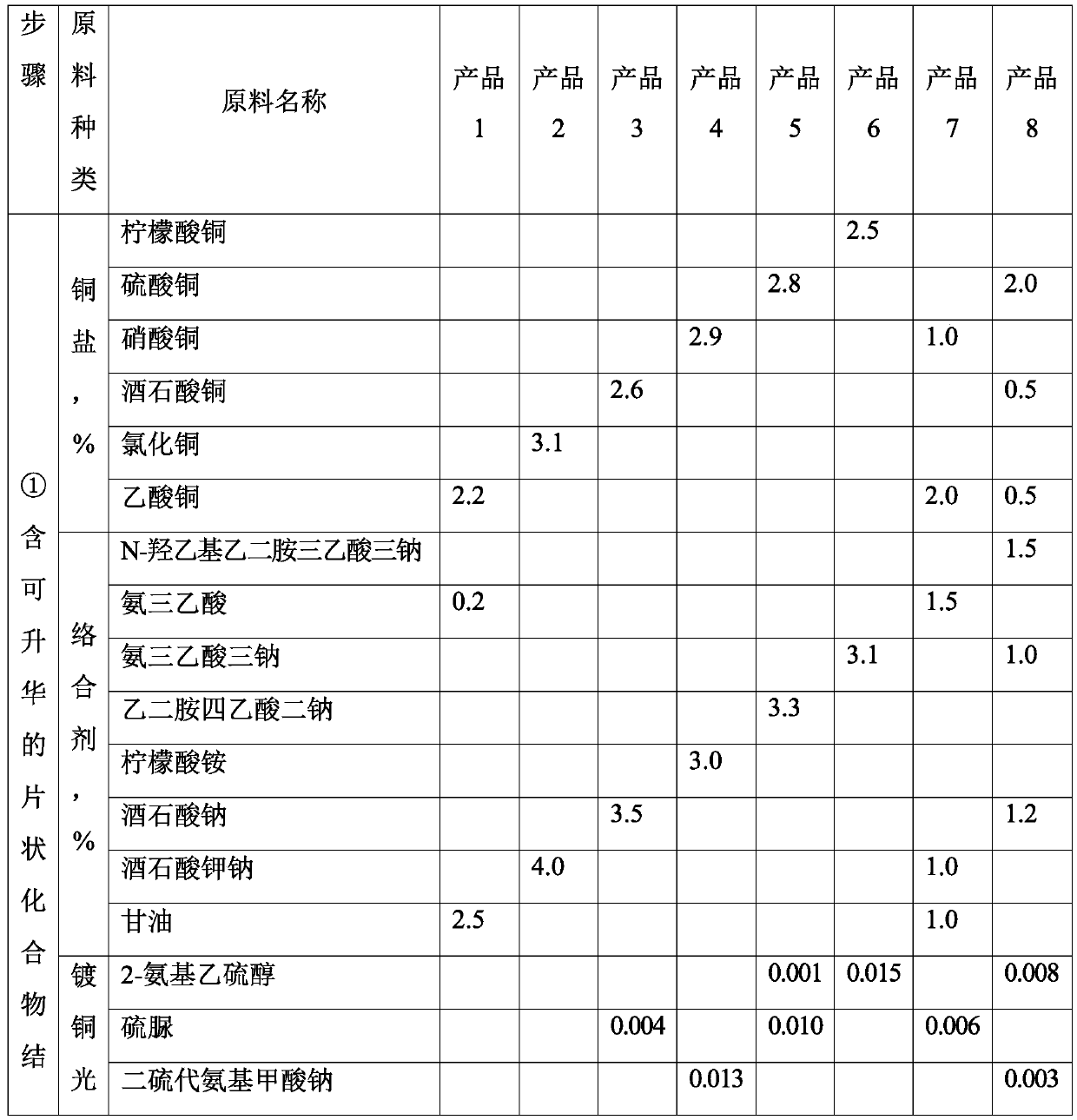

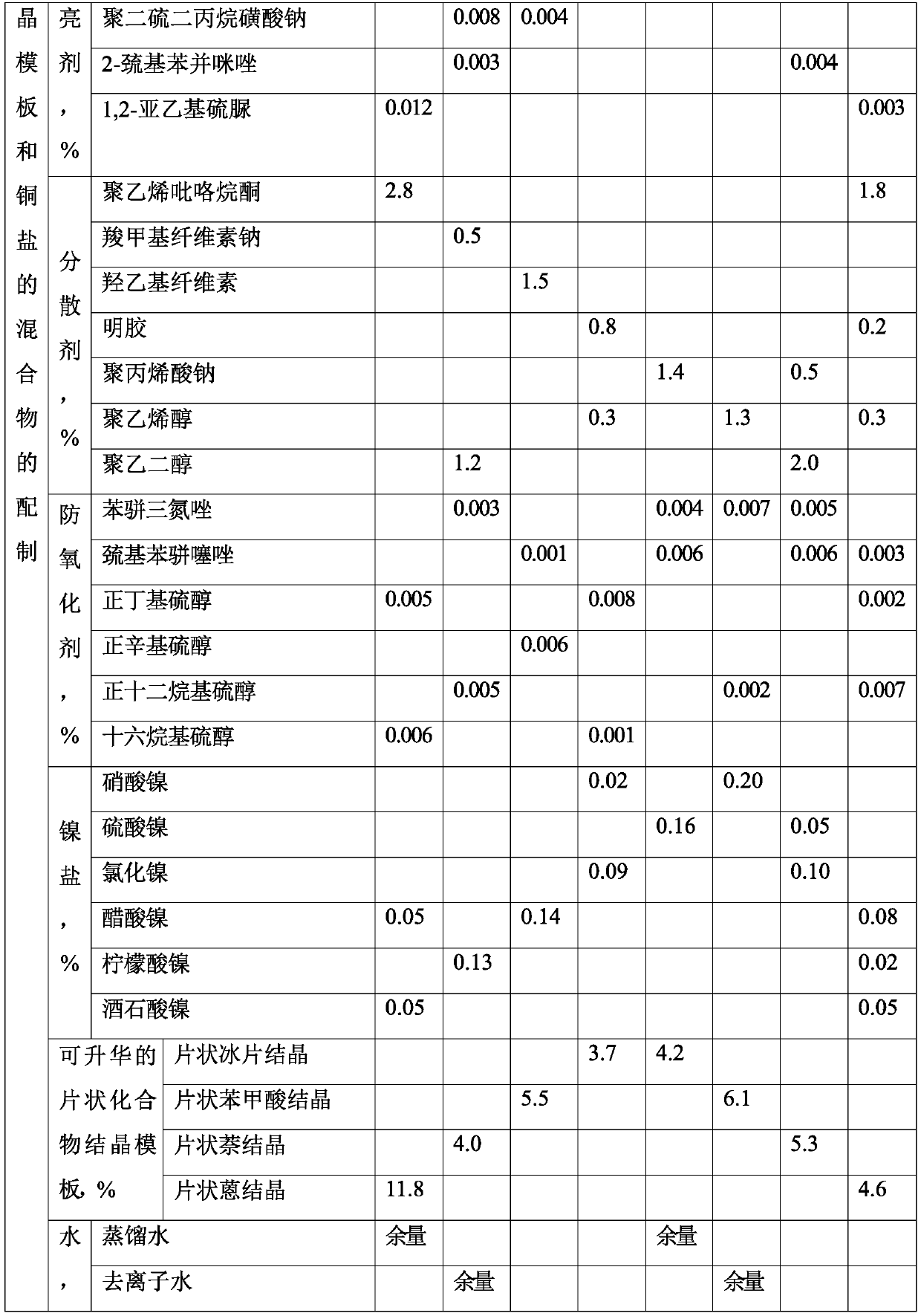

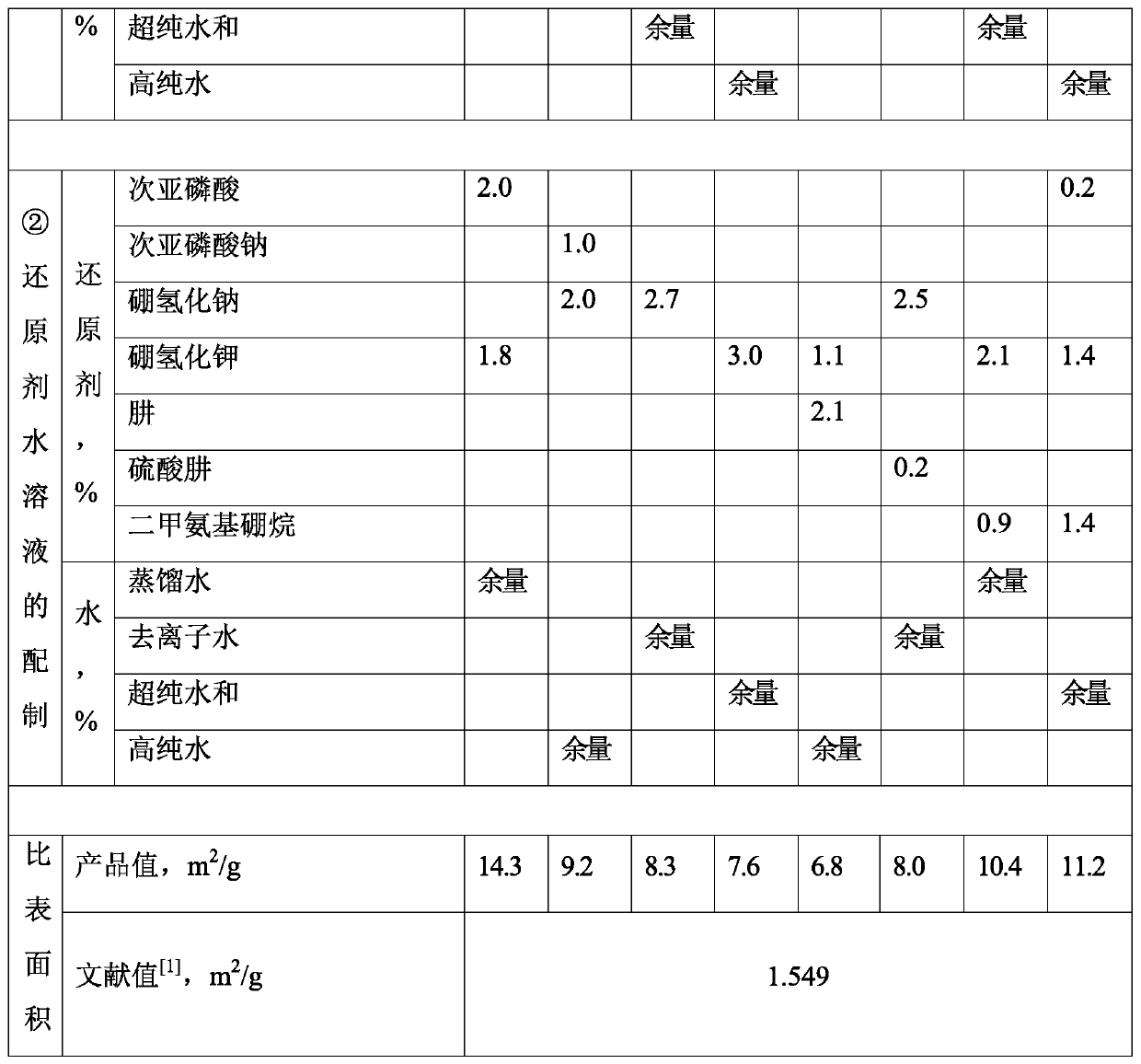

[0060] 1) Preparation of a mixture containing sublimable flaky compound crystallization template and copper salt: water, copper salt, complexing agent, copper plating brightener, dispersant, antioxidant, nickel salt according to products 1 to 8 in Table 1. With the mass percentage of the sublimable flake compound crystallization template, first mix water, copper salt, complexing agent, copper plating brightener, dispersant, antioxidant and nickel salt, stir until all materials are completely dissolved, and then add sublimable The flaky compound crystal template is stirred and ultrasonically treated for 1-60min. The sublimable flaky compound crystal template is ultrasonically crushed into flaky crystals with a particle size of 0.5-20.0μm, and the sublimable flakes are obtained. A mixture of a crystalline template and a copper salt.

[0061] 2) Preparation of the reducing agent aqueous solution:...

Embodiment 2

[0069] A preparation method of flake copper powder in acid medium, the specific steps are as follows:

[0070] 1) Preparation of flaky acidic compound crystal template: According to the mass percentages of surfactants, acidic compound crystals and water of products 1-8 in Table 2, first mix the water with the surfactant, stir and dissolve completely to obtain the surface Active agent aqueous solution; heat the surfactant aqueous solution to boiling, add acidic compound crystals and stir until fully dissolved, filter while hot to obtain a saturated solution of acidic compound crystals; place the saturated solution of acidic compound crystals in a thermostat controlled at 50°C Medium cooling crystallization, when the temperature of the material drops to 50 ℃, take the material out of the thermostat, and then let the material cool to room temperature naturally, so that the crystallization is complete; the material is filtered to obtain the flake acidic compound crystalline crude prod...

Embodiment 3

[0082] A preparation method of flake copper powder in acid medium, the specific steps are as follows:

[0083] 1) Preparation of flaky basic compound crystal template: According to the mass percentages of surfactants, basic compound crystals and water in products 1-8 in Table 3, first mix the water with the surfactant, stir and dissolve completely, then Obtain a surfactant aqueous solution; heat the surfactant aqueous solution to boiling, add the crystals of the alkaline compound and stir until fully dissolved, filter while hot to obtain a saturated solution of the crystals of the alkaline compound; place the saturated solution of the crystals of the alkaline compound in the temperature control Cool and crystallize in a 50°C incubator. When the temperature of the material drops to 50°C, take out the material from the incubator, and then let the material cool to room temperature to complete the crystallization; the material is filtered to obtain the flaky basic compound crystalline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com