Hollow aluminum alloy microsphere preparation device and preparation method

A preparation device and aluminum alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of incompleteness, complex process, complex physical and chemical reactions, etc., and achieve the effect of short production process, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

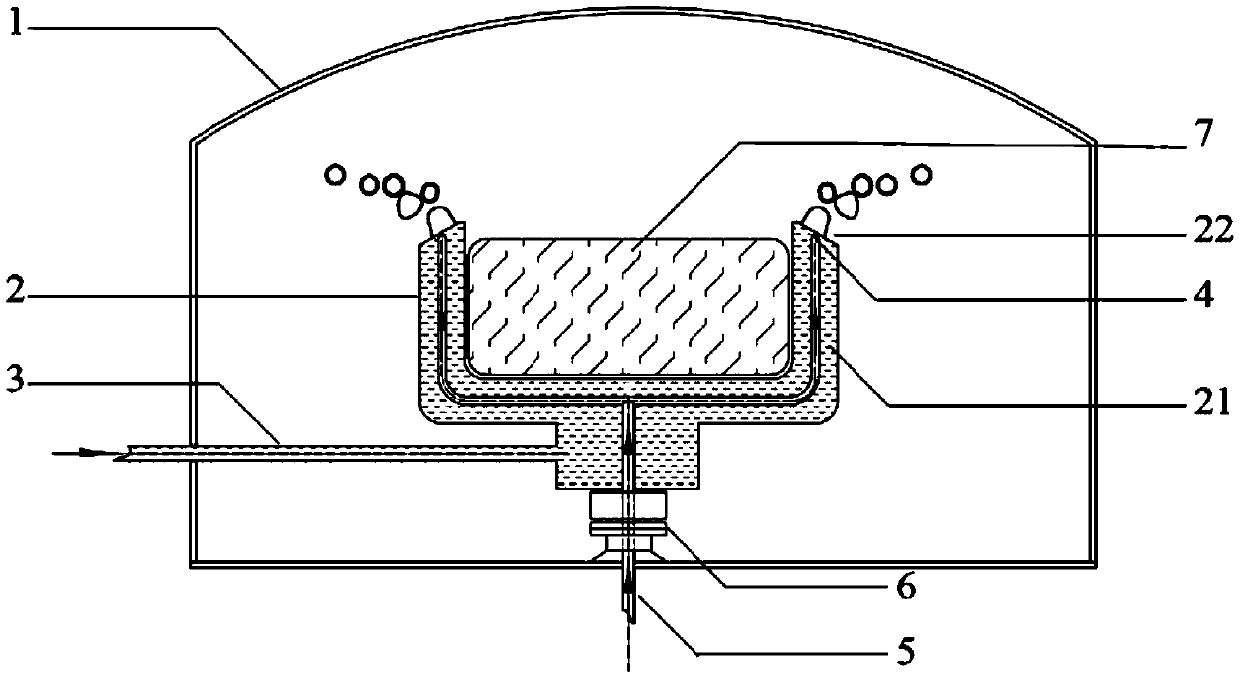

[0052] Heat and melt the A356 aluminum alloy to 680℃, and add Al with a particle size of 5μm that has been preheated at 400℃ for 2h 2 O 3 Particles, Al 2 O 3 The amount of particles added is 10vol%, and mechanical stirring is carried out to the added Al 2 O 3 The particles are uniformly dispersed in the melt, and the obtained aluminum alloy melt is used in the subsequent preparation process.

[0053] The sealed shell 1 is evacuated and filled with argon as a protective gas. When the temperature of the aluminum alloy melt is 680°C, it is fed into the hollow cavity 21 through the liquid inlet pipe 3, so that the hollow cavity 21 is filled with the aluminum alloy melt. Adjust the vibrator 6 to adjust the vibration frequency of the blowing head 4 to 100 Hz. At the same time, argon is blown into the blowing head 4 through the air inlet pipe 5 at a flow rate of 15 mL / min, and the argon is blown to the aluminum through the blowing head 4. On the surface of the alloy melt, hollow aluminum...

Embodiment 2

[0057] Heat and melt pure aluminum to 750°C, and add TiO with a particle size of 5μm that has been preheated at 400°C for 2 hours 2 Particles, TiO 2 The added amount of particles is 8vol%, and mechanically stir until the added TiO 2 The particles are uniformly dispersed in the melt, and the obtained aluminum alloy melt is used in the subsequent preparation process.

[0058] The sealed shell 1 is evacuated and filled with argon as a protective gas. When the temperature of the aluminum alloy melt is 680°C, it is fed into the hollow cavity 21 through the liquid inlet pipe 3, so that the hollow cavity 21 is filled with the aluminum alloy melt. Adjust the vibrator 6 to adjust the vibration frequency of the blowing head 4 to 150 Hz. At the same time, argon is introduced into the blowing head 4 through the air inlet pipe 5 at a flow rate of 10 mL / min, and the argon is blown to the aluminum through the blowing head 4. On the surface of the alloy melt, hollow aluminum alloy microspheres ar...

Embodiment 3

[0062] Heat and melt the A356 aluminum alloy to 700°C, add CuO particles with a particle size of 10μm that have been preheated at 400°C for 2 hours. The addition amount of CuO particles is 5vol%, and mechanically stir until the added CuO particles are evenly dispersed in the melt. The obtained aluminum alloy melt is used in the subsequent preparation process.

[0063] The sealed shell 1 is evacuated and filled with helium gas as a protective gas. When the temperature of the aluminum alloy melt is 680°C, it is fed into the hollow cavity 21 through the liquid inlet pipe 3, so that the hollow cavity 21 is filled with the aluminum alloy melt. Adjust the vibrator 6 to adjust the vibration frequency of the blowing head 4 to 90 Hz. At the same time, nitrogen is blown into the blowing head 4 through the air inlet pipe 5 at a flow rate of 20 mL / min, and the nitrogen is blown to the aluminum alloy through the blowing head 4. On the surface of the body, hollow aluminum alloy microspheres ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com