Positive electrode material of lithium ion cell and its preparation method

A technology for lithium ion batteries and positive electrode materials is applied in the field of positive electrode materials for lithium ion batteries and their preparation, and can solve the problems of sacrificing volume energy density and mass energy density, particle size distribution range, low conductivity of lithium iron phosphate, etc. Achieve the effect of improving electrochemical activity, simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the Fe and P molar ratio of 1: 1, the ferrous phosphate aqueous solution with a mass percentage concentration of 11.2% and the lithium phosphate aqueous solution with a mass percentage concentration of 9.7% are mixed uniformly, and then the OP-10 aqueous solution with a mass percentage concentration of 10% is added to carry out Mixing and stirring, where each mole of PO 4 3+ Add 10g of OP-10, control the temperature at 45-55°C to make it precipitate, then filter, wash and dry the precipitate. Heat-treat the dried precursor in a nitrogen flow at 650-800°C for 8-12.5 hours to obtain a lithium iron phosphate precursor.

[0026] With 23.6% Cu(NO 3 ) 2 The aqueous solution is mixed with lithium iron phosphate particles, and the ratio of the two is to add 0.01 mole of copper nitrate per mole of lithium iron phosphate, and stir in vacuum for 0.5h to form a paste. Then add 40% vitamin C aqueous solution, add 2.5 moles of vitamin C per mole of copper nitrate, an...

Embodiment 2

[0037] The preparation of the lithium-ion battery cathode material and the fabrication and testing of the experimental battery are the same as in Example 1. But the following parameters have changed:

[0038] The mass percent concentration of the ferrous phosphate aqueous solution is 10.9%, the mass percent concentration of the lithium phosphate aqueous solution is 9.7%; the mass percent concentration of the stabilizer OP-10 aqueous solution is 17.5%, and its addition is per mole of PO 4 3+ Add 7.5g of OP-10; the mass percent concentration of the copper nitrate solution is 33%, and its addition is 0.08 moles of copper nitrate per mole of lithium iron phosphate; the mass percent concentration of the vitamin C aqueous solution is still 40%, and its addition Add 3.5 moles of vitamin C for every mole of copper nitrate.

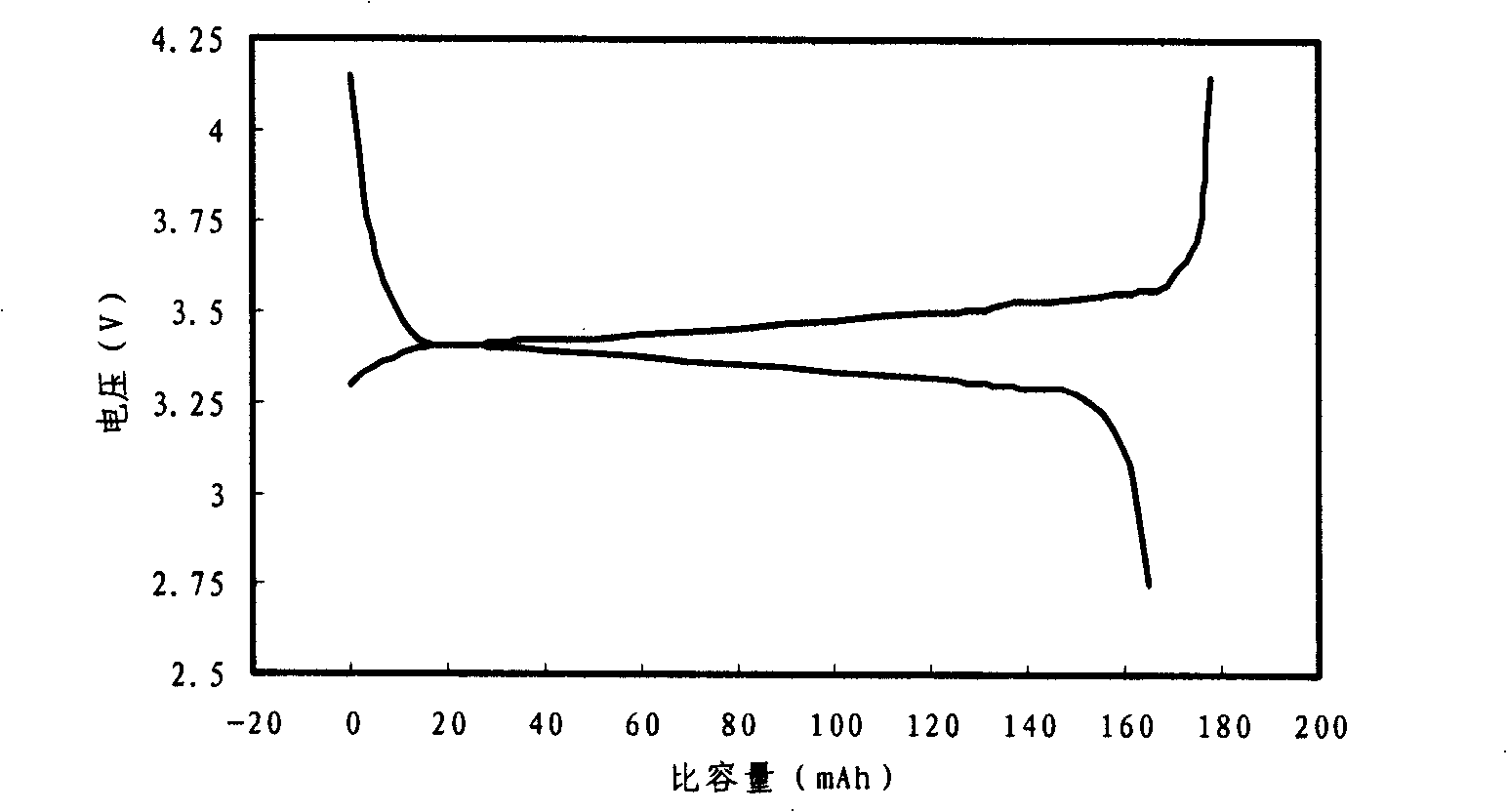

[0039] The tap density of the prepared lithium-ion battery positive electrode material is 1.53g / cm 3 , its initial discharge specific capacity in the experimen...

Embodiment 3

[0041] The preparation of the lithium-ion battery cathode material and the fabrication and testing of the experimental battery are the same as in Example 1. But the following parameters have changed:

[0042] The mass percent concentration of the ferrous phosphate aqueous solution is 12.2%, the mass percent concentration of the lithium phosphate aqueous solution is 10.1%; the mass percent concentration of the stabilizer OP-10 aqueous solution is 12.2%, and its addition is per mole of PO 4 3+ Add the OP-10 of 9g; The mass percent concentration of copper nitrate solution is 27%, and its add-on is that every mole lithium iron phosphate adds 0.2 mole of copper nitrate; The mass percent concentration of vitamin C aqueous solution is still 40%, and its add-on is Add 1.9 moles of vitamin C per mole of copper nitrate.

[0043] The tap density of the prepared lithium-ion battery positive electrode material is 1.57g / cm 3 , its initial discharge specific capacity in the experimental b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com