Molybdate and preparation method thereof

A technology of molybdate and molybdenum source, which is applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve the problems of difficult synthesis and difficult synthesis of nanostructured molybdate materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

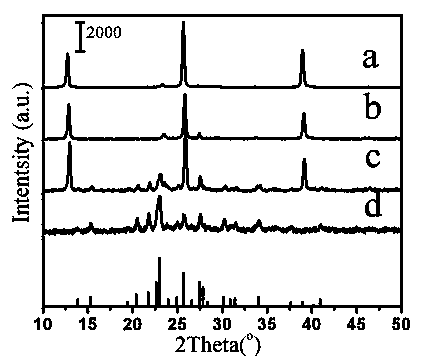

Embodiment 1

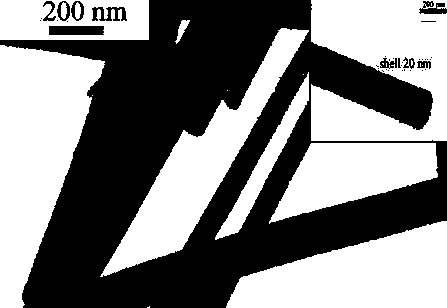

[0033] Take commercial molybdenum oxide powder 10mmol and add to 70ml of 30% H 2 o 2 solution, stirred at room temperature for 1 day, then transferred to a hydrothermal reaction kettle, and kept in an oven at 180°C for 24 hours. Then it is taken out, centrifuged, washed three times with deionized water, then washed three times with ethanol, and dried at low temperature to obtain a white powder, which is a molybdenum oxide nanometer square rod material.

[0034] Add the molybdenum oxide nano-square rod-shaped material prepared above into the mixed system of water and ethanol, the weight ratio of water and ethanol is 5 / 1, stir at 70°C for half an hour, and then add FeCl 3 Alcohol aqueous solution, added to the above suspension system, wherein, FeCl 3 with MoO 3The molar ratio is 2:3; then, aging for 24 hours to obtain a brownish-red suspension, centrifuged, washed three times with deionized water, then washed three times with ethanol, and dried at low temperature to obtain a ...

Embodiment 2

[0038] 2 M hydrochloric acid was added dropwise to 10 mmol of ammonium heptamolybdate solution, stirred at room temperature for 2 days, then 70 ml of the solution was transferred to a hydrothermal reaction kettle, and kept in an oven at 180°C for 24 hours. Then it is taken out, centrifuged, washed three times with deionized water, then washed three times with ethanol, and dried at low temperature to obtain a white powder, which is a molybdenum oxide nanometer square rod material.

[0039] Add the molybdenum oxide nano-square rod-shaped material prepared above into the mixed system of water and ethanol, the weight ratio of water and ethanol is 10 / 1, stir at 100°C for 1 hour, and then add FeCl 3 Alcohol aqueous solution, added to the above suspension system, FeCl 3 with MoO 3 The molar ratio is 1:1; then, aging for 24 hours to obtain a brown-red suspension, centrifuged, washed three times with deionized water, then washed three times with ethanol, and dried at low temperature t...

Embodiment 3

[0043] Take commercial molybdenum oxide powder 10mmol and add to 70ml of 30% H 2 o 2 solution, stirred at room temperature for 1 day, then transferred to a hydrothermal reaction kettle, and kept in an oven at 180°C for 24 hours. Then it is taken out, centrifuged, washed three times with deionized water, then washed three times with ethanol, and dried at low temperature to obtain a white powder, which is a molybdenum oxide nanometer square rod material.

[0044] Add the molybdenum oxide nanometer square rod material prepared above into the mixed system of water and propanol, the weight ratio of water and propanol is 5 / 1, stir at 70°C for half an hour, and then add FeCl 3 Alcohol aqueous solution, added to the above suspension system, wherein, FeCl 3 with MoO 3 The molar ratio is 3:4; then, aging for 24 hours to obtain a brown-red suspension, centrifuged, washed three times with deionized water, then washed three times with ethanol, and dried at low temperature to obtain a da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com