Catalytic removal device for NOx and CO in tail flue of pi-shaped pulverized coal boiler

A tail flue and pulverized coal boiler technology, which is applied in lighting and heating equipment, combustion product treatment, combustion methods, etc., can solve the problems of boiler efficiency reduction and low investment in transformation, and achieve secondary pollution and easy replacement and transformation , The effect of reducing CO and NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

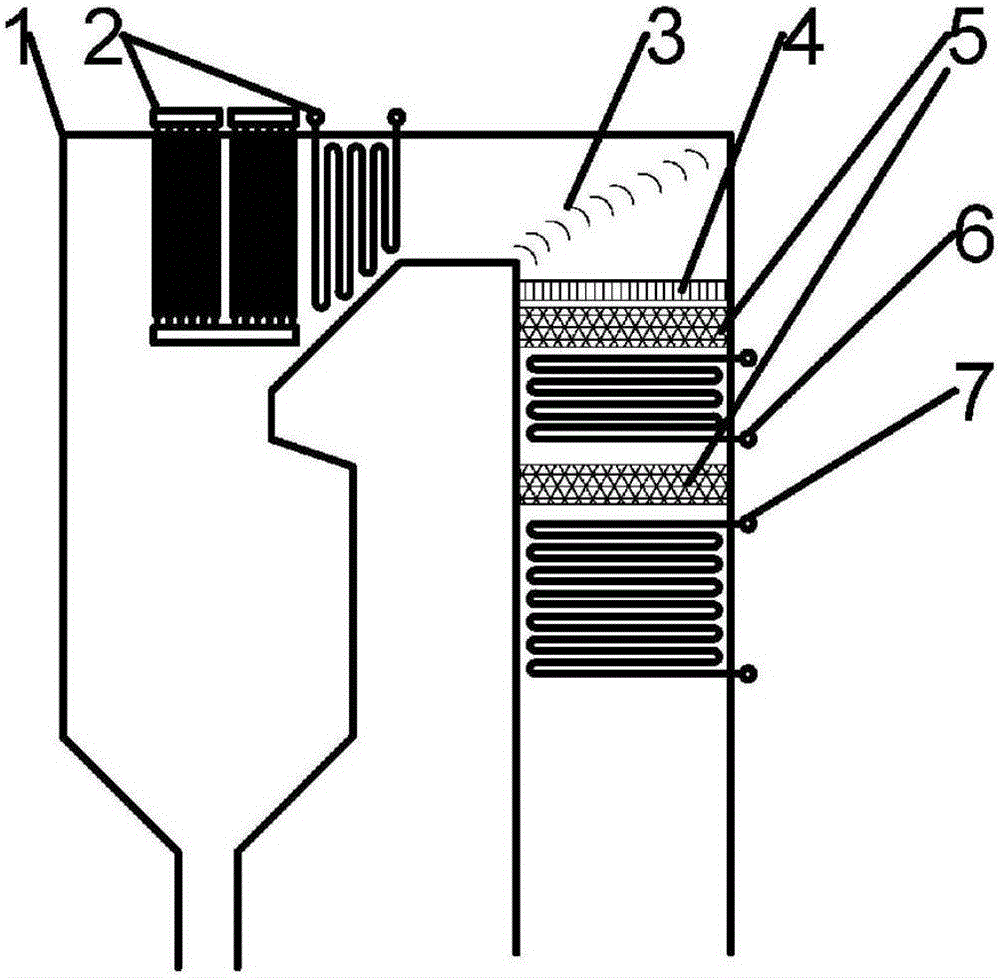

[0029] Such as figure 1 As shown, in this embodiment, a π-type pulverized coal boiler tail flue NOx and CO catalytic removal device includes a π-type pulverized coal boiler tail flue 1, a panel heating surface 2, a deflector 3, and a rectifying grid 4 , active catalytic material 5, low temperature reheater 6, low temperature superheater 7, etc. The active catalytic material 5 is arranged upstream of the heating surface of the low-temperature reheater 6 and upstream of the heating surface of the low-temperature superheater 7, in the form of a honeycomb, and its main component is 12Cr2MoWVTiB. Using low-oxygen combustion technology, the CO concentration in the flue gas at the two places on the panel heating surface is 3000ppm, and the NO concentration is 200ppm. After catalytic reaction, the CO emission concentration is reduced to 100ppm, and the NO emission concentration is reduced to 70ppm.

Embodiment 2

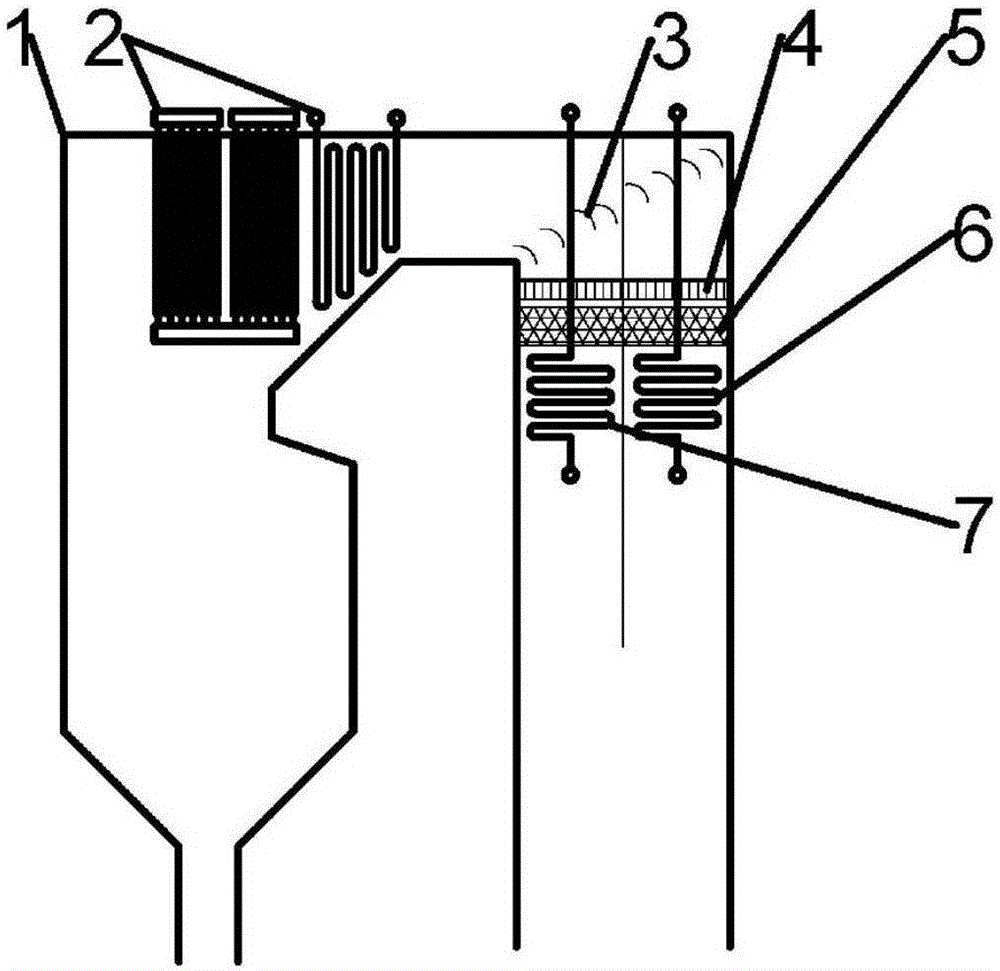

[0031] Such as figure 2 As shown, in this embodiment, a π-type pulverized coal boiler tail flue NOx and CO catalytic removal device includes a π-type pulverized coal boiler tail flue 1, a panel heating surface 2, a deflector 3, and a rectifying grid 4 , active catalytic material 5, low temperature superheater 6, low temperature reheater 7, etc. The tail flue of the π-type pulverized coal boiler is divided into front and rear double flues. There is a low-temperature reheater 7 in the flue near the front of the furnace, and a low-temperature superheater 6 in the flue near the rear of the furnace. The rectifying grid 4 and the active catalytic material 5 are also divided into two parts, which are respectively arranged in front of the heating surface of the low-temperature superheater 7 of the front flue and upstream of the heating surface of the low-temperature reheater 6 of the rear flue. The active catalytic material 5 is in the form of a corrugated plate, and its main compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com