Method for preparing ZnFe2O4/Fe2O3 three-dimensional heterojunction nano-material by magnetron sputtering

A technology of magnetron sputtering and nanomaterials, applied in sputtering plating, metal material coating process, ion implantation plating, etc., can solve the problems of low specific surface area and inability to obtain catalytic effect, and achieve low cost and improved Photocatalytic performance, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

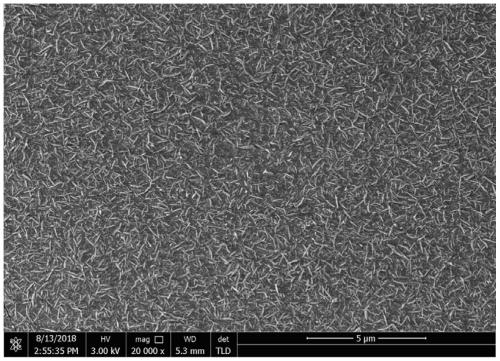

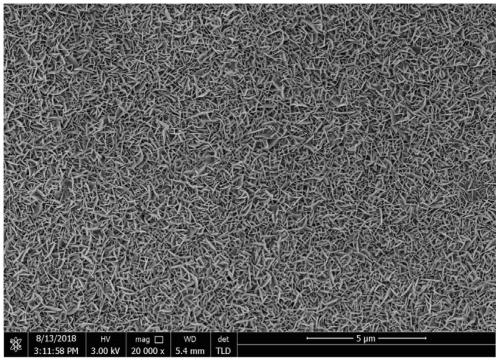

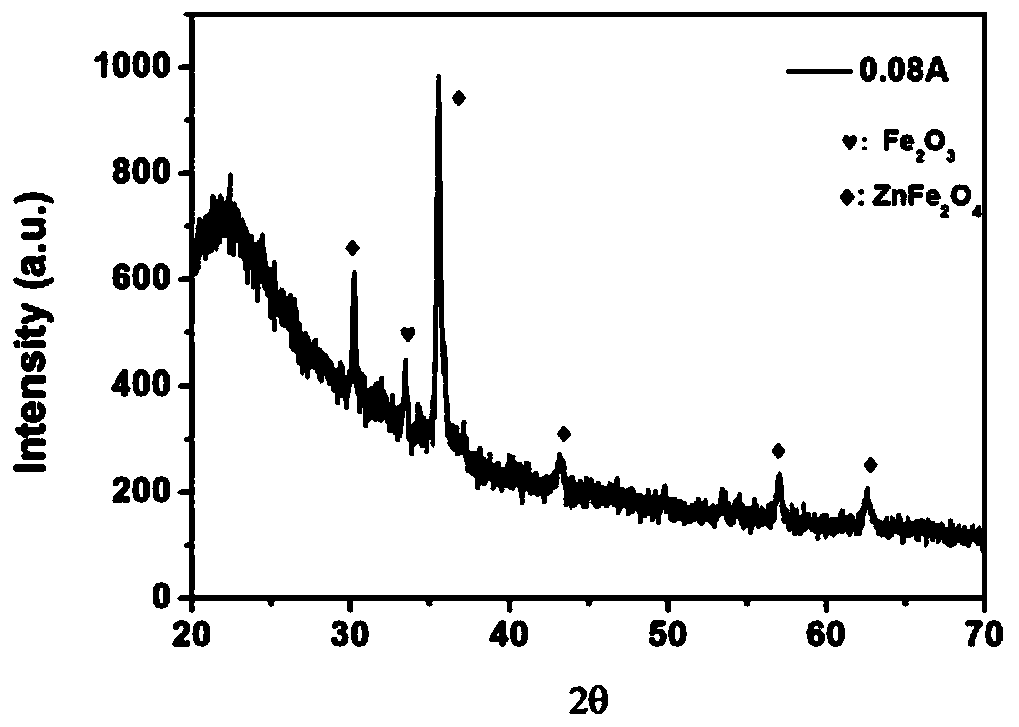

[0027] A kind of magnetron sputtering to prepare ZnFe 2 O 4 / Fe 2 O 3 The method of three-dimensional heterojunction nanomaterials is based on magnetron sputtering technology. In a closed environment, Fe and ZnO are used as targets respectively, and quartz sheets are used as substrates, and the angle between the substrate and the horizontal plane is adjusted to 0°~5° , adjust the distance between the ZnO target and the substrate to 9cm ~ 10cm, adjust the distance between the Fe target and the substrate to 12cm ~ 13cm, and then vacuumize the airtight environment, and reduce the air pressure in the airtight environment to 2×10 -4 At Pa, argon gas was introduced into the airtight environment as sputtering gas; then the air pressure in the airtight environment was controlled to be 0.15Pa ~ 0.2Pa, and then the Fe target was sputtered by a DC sputtering source, and the ZnO target was sputtered by a radio frequency sputtering source. For sputtering, the Fe target and the ZnO targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com