Method for preparing sulfur battery positive pole by using protein

A sulfur battery and protein technology, which is applied in the field of preparing sulfur battery anodes by using proteins, can solve the problems such as difficulty in preparing porous materials with small porosity, sulfur battery research is only in the experimental stage, and cannot meet commercial requirements, etc. Reduce the possibility of explosion and facilitate the effect of sulfur loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

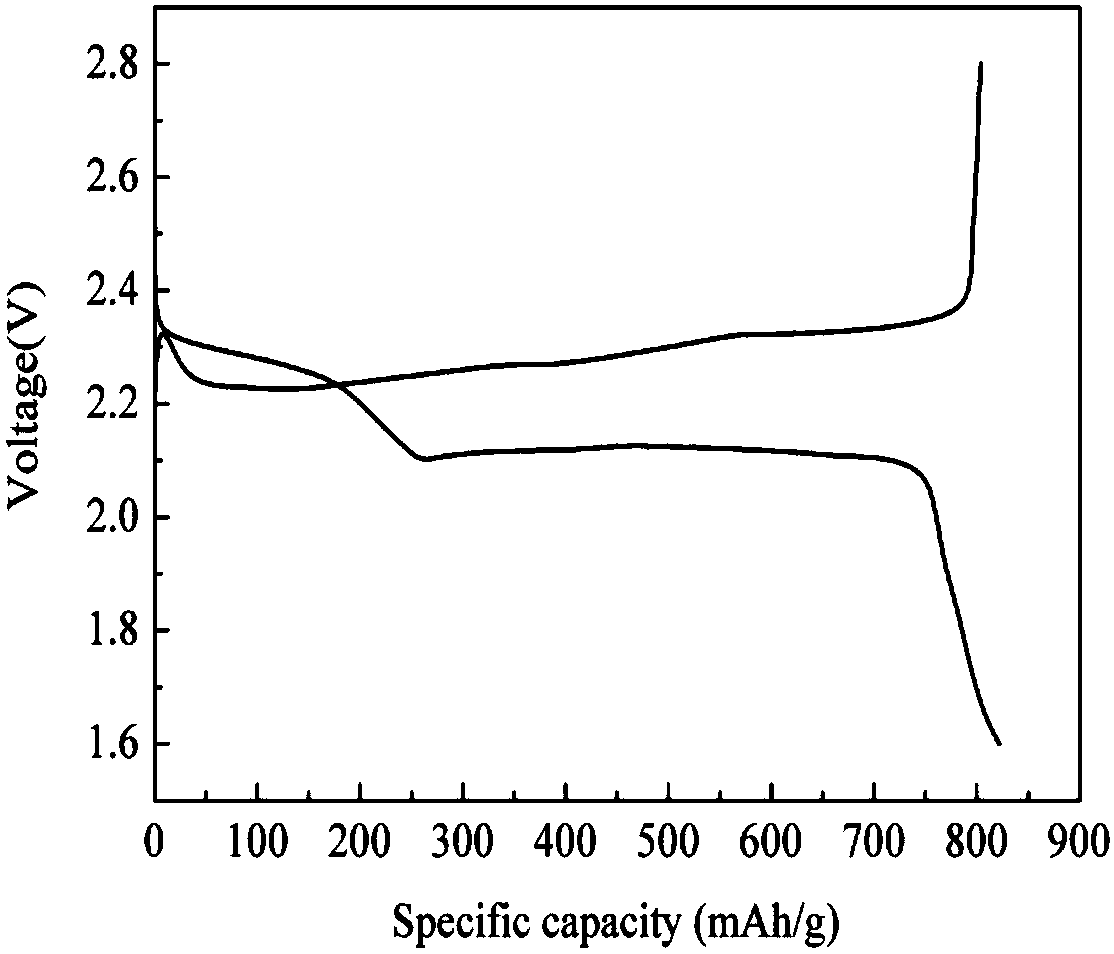

Image

Examples

preparation example Construction

[0030] The preparation process of alkaline alum water is as follows:

[0031] Alum is dissolved in distilled water to prepare alum water, wherein 15g to 25g of alum is added per liter of distilled water; the pH value of the alum water is adjusted to 10 with NaOH.

[0032] Step 2, drying the pasty mixture obtained in step 1 to obtain lumps;

[0033] During the drying process: the drying temperature is controlled at 90°C to 110°C, and the drying time is controlled at 20min to 60min.

[0034] Step 3, putting the block obtained in step 2 into a sintering furnace with nitrogen for calcination to obtain a powder;

[0035] In the calcination process: the nitrogen pressure is 0.11MPa-0.12MPa, the sintering temperature is 800°C-850°C, and the sintering time is 3.5h-4h.

[0036] Step 4, mixing the powder obtained in step 3 with sublimed sulfur and then grinding to obtain a mixed powder, and then heat-treating the obtained mixed powder to obtain a sulfur-loaded C-N powder, specifically...

Embodiment 1

[0046] Step 1. Weigh egg white, starch and alkaline alum water respectively according to the mass ratio of 1:0.5:1, and mix the weighed egg white, starch and alkaline alum water together to form a paste mixture; wherein, The preparation process of alkaline alum water is: dissolving alum in distilled water is mixed with alum water, wherein every liter of distilled water adds the alum of 15g, adjusts the pH value of alum water to 10 with NaOH;

[0047] Step 2, drying the pasty mixture obtained in step 1 to obtain lumps;

[0048] During the drying process: the drying temperature is controlled at 90°C, and the drying time is controlled at 60 minutes;

[0049] Step 3, putting the block obtained in step 2 into a sintering furnace with nitrogen for calcination to obtain a powder;

[0050] In the calcination process: the nitrogen pressure is 0.11MPa, the sintering temperature is 800°C, and the sintering time is 4h;

[0051] Step 4, mixing the powder obtained in step 3 with sublimed ...

Embodiment 2

[0059]Step 1. Weigh egg white, starch and alkaline alum water respectively according to the mass ratio of 1.5:1:1, and mix the weighed egg white, starch and alkaline alum water together to form a paste mixture; wherein, The preparation process of alkaline alum water is: dissolving alum in distilled water is mixed with alum water, wherein every liter of distilled water adds the alum of 18g, adjusts the pH value of alum water to 10 with NaOH;

[0060] Step 2, drying the pasty mixture obtained in step 1 to obtain lumps;

[0061] During the drying process: the drying temperature is controlled at 95°C, and the drying time is controlled at 55 minutes;

[0062] Step 3, putting the block obtained in step 2 into a sintering furnace with nitrogen for calcination to obtain a powder;

[0063] In the calcination process: the nitrogen pressure is 0.11MPa, the sintering temperature is 810°C, and the sintering time is 4h;

[0064] Step 4, mixing the powder obtained in step 3 with sublimed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com