Method for synthesizing phosphatidylcholine by using solid-phase carrier

A technology for synthesizing phosphatidylcholine and phosphatidylcholine, which is applied in the field of medicine and chemical industry, can solve the problems of unsuitability for industrial production, harsh preparation method conditions, cumbersome post-processing procedures, etc., and achieve easy large-scale industrial production and increase molecular collisions chance, the effect of increasing the reaction surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Add 51.4g glycerol phosphorylcholine into a clean and dry 3000ml three-necked bottle with mechanical stirring, replace nitrogen, start stirring, heat until glycerol phosphorylcholine melts, and add different adsorbents (adsorbent selection From activated carbon, aluminum oxide, silica gel, diatomaceous earth) 154.2g, continue to stir for 1 hour, make glycerol phosphorylcholine fully and evenly adsorbed by the adsorbent.

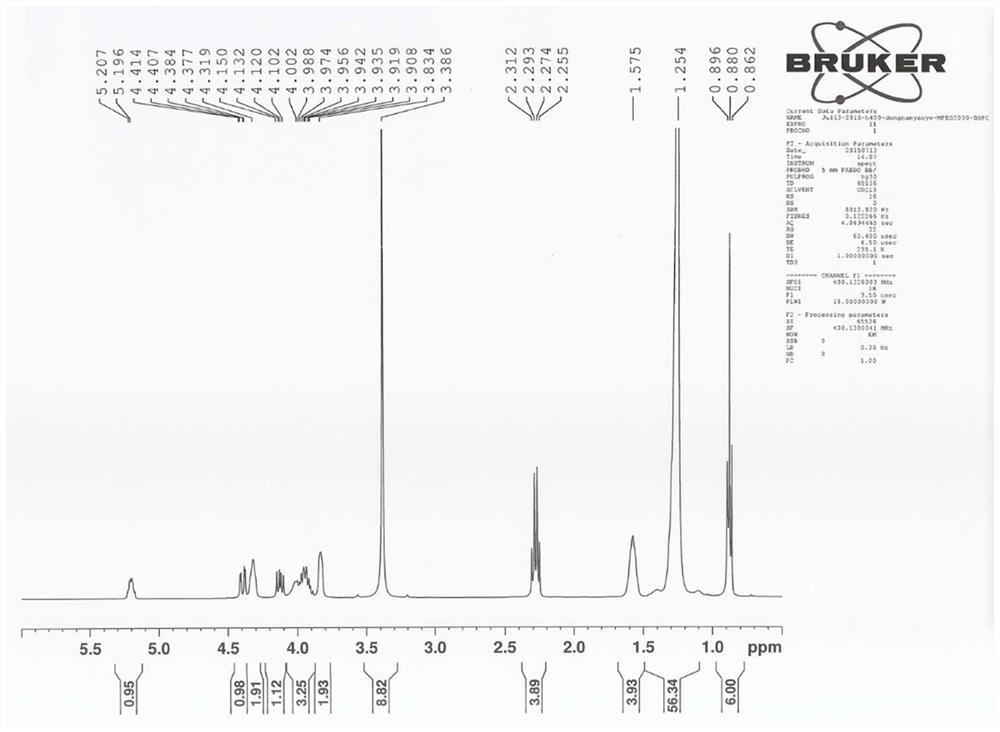

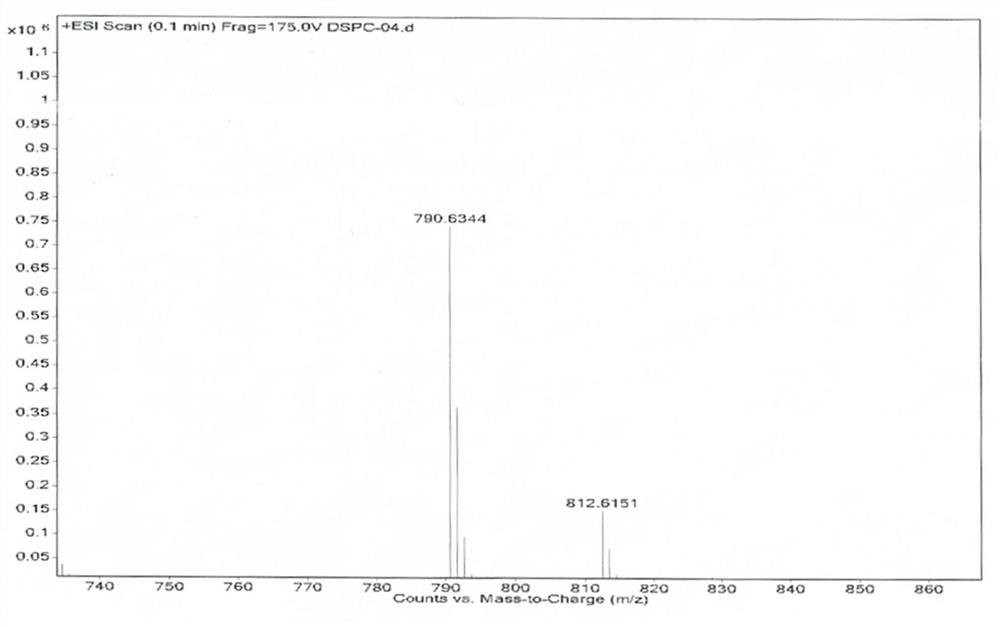

[0040] (2) Cool down to room temperature, add 1500 mL of chloroform and 60.7 g of triethylamine, add 181.75 g of stearyl chloride dropwise at a temperature of 20°C, after the addition is complete, keep stirring for 1 hour, heat up to 30-35°C, filter, Transfer the filtrate to a clean and dry 3000ml three-neck flask with mechanical stirring, start the stirring, cool down to -5~5°C for crystallization for 3~4 hours, filter, rinse the filter cake with a small amount of ice chloroform, drain it, and dry it in vacuum for 24 hours. Hours, DSPC137.5g was o...

Embodiment 2

[0049] (1) Add 51.4g of glycerol phosphorylcholine into a clean and dry 3000ml three-necked bottle with mechanical stirring, replace the nitrogen, start stirring, heat until the glycerol phosphorylcholine melts, add 154.2g of activated carbon under stirring, and continue stirring for 1 hour , so that glycerol phosphorylcholine is fully and evenly adsorbed by activated carbon.

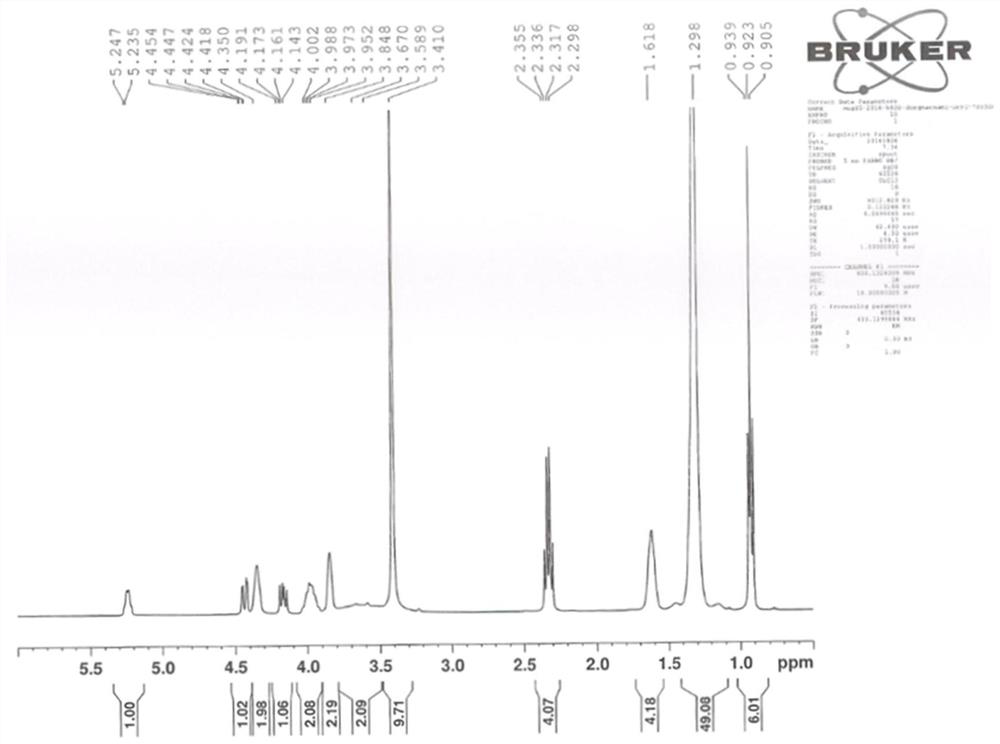

[0050](2) Cool down to room temperature, add 1500 mL of chloroform and 60.7 g of triethylamine, add 164.92 g of palmitoyl chloride dropwise under temperature control at 20°C, after the addition is complete, keep stirring for 1 hour, heat up to 30-35°C, filter, and the filtrate Transfer to a clean and dry 3000ml three-neck flask with mechanical stirring, turn on the stirring, cool down to -5~5°C to crystallize for 3~4 hours, filter, rinse the filter cake with a small amount of ice chloroform, drain, and vacuum dry for 24 hours , to obtain DPPC 130.1g, yield 88.6%.

[0051] the resulting product, 1 H-NM...

Embodiment 3

[0053] (1) Add 51.4g of glycerol phosphorylcholine into a clean and dry 3000ml three-necked bottle with mechanical stirring, replace the nitrogen, start stirring, heat until the glycerol phosphorylcholine melts, add 154.2g of activated carbon under stirring, and continue stirring for 1 hour , so that glycerol phosphorylcholine is fully and evenly adsorbed by activated carbon.

[0054] (2) Cool down to room temperature, add 1500 mL of chloroform and 60.7 g of triethylamine, add 214.21 g of erucic acid chloride dropwise at a temperature of 20°C, after the addition is complete, keep stirring for 1 hour, heat up to 30-35°C, and filter. Transfer the filtrate to a clean and dry 3000ml three-neck flask with mechanical stirring, start the stirring, cool down to -10-0°C to crystallize for 3-4 hours, filter, rinse the filter cake with a small amount of ice chloroform, drain it, and dry it in vacuum for 24 hours. Hours, DEPC 154.7g was obtained with a yield of 86.1%.

[0055] the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com