Method for producing membrane electrode assembly

a membrane electrode and assembly technology, applied in the direction of electrochemical generators, cell components, coatings, etc., can solve the problems of increasing the cost of power generation, and increasing the cost of energy consumption, so as to reduce the sliding effect, improve the reaction surface area, and improve the performance of the membrane electrode assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

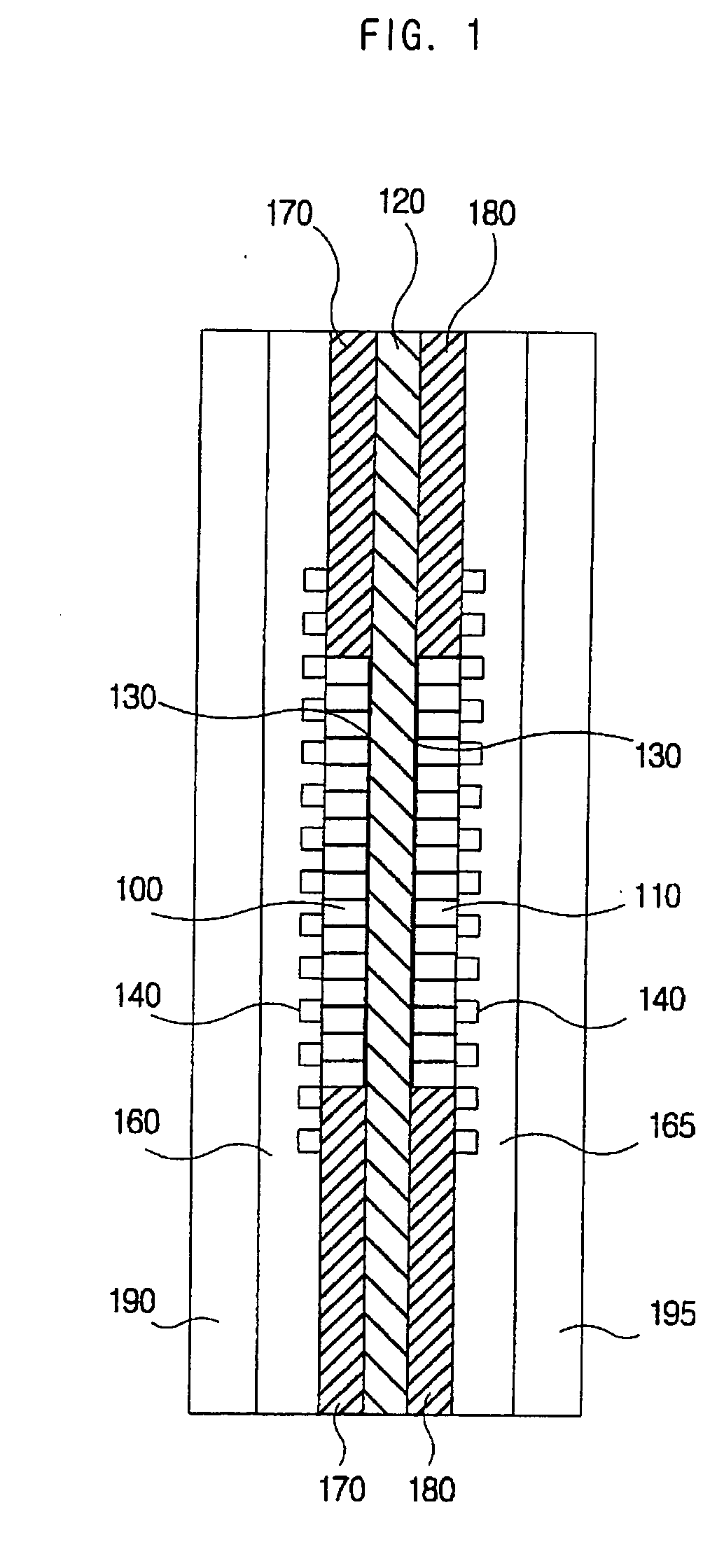

[0100] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings, but it is understood that the present invention should not be limited to the following embodiments.

[0101] To help in understanding the present invention, preferred embodiments of the present invention will be described centering around PEFC (Polymer Electrolyte Fuel Cells), however, it should be understood that the present invention should not be limited to the PEFC (Polymer Electrolyte Fuel Cells).

[0102] That is to say, the present invention can be applied to cells that supply fuel through a porous electrode, for example, PEFC using fuel in a gas state, DMFC using fuel in a liquid state, and SOFC using an electrolyte in a solid state.

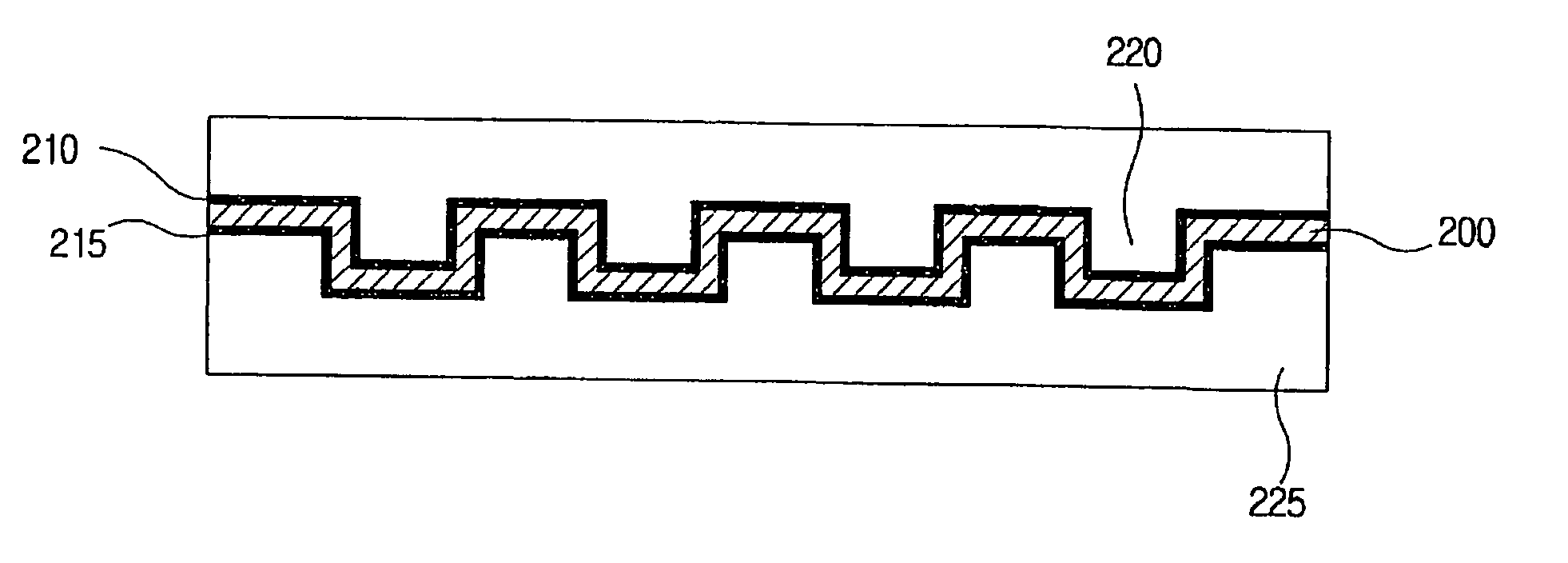

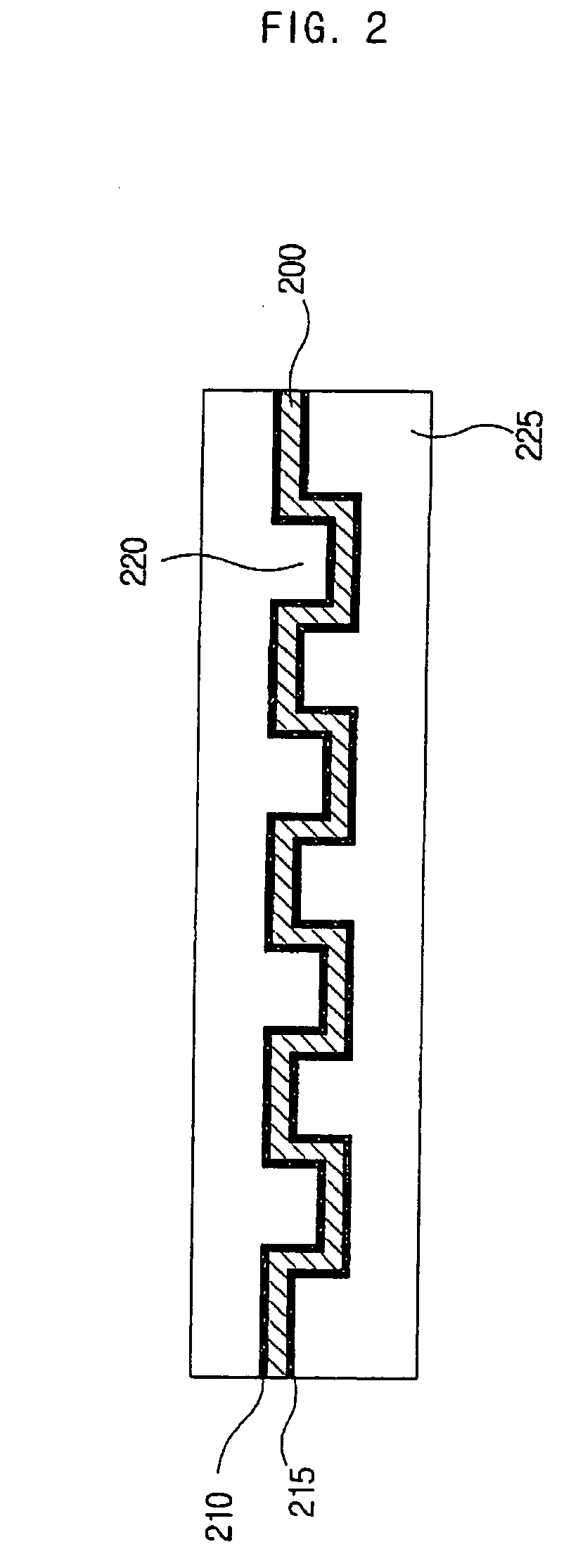

[0103]FIG. 2 is a schematic cross section of a membrane electrode assembly in accordance with one preferred embodiment of the present invention.

[0104] The present invention provides a membrane electrode as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com