Catalytic-cracking metal passivator

A metal deactivator and catalytic cracking technology, which is applied in catalytic cracking, catalyst protection, cracking, etc., can solve the problems of catalyst poison deactivation selectivity, increase of hydrogen and coke yield, and decrease of light oil yield. Low toxicity, low freezing point, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

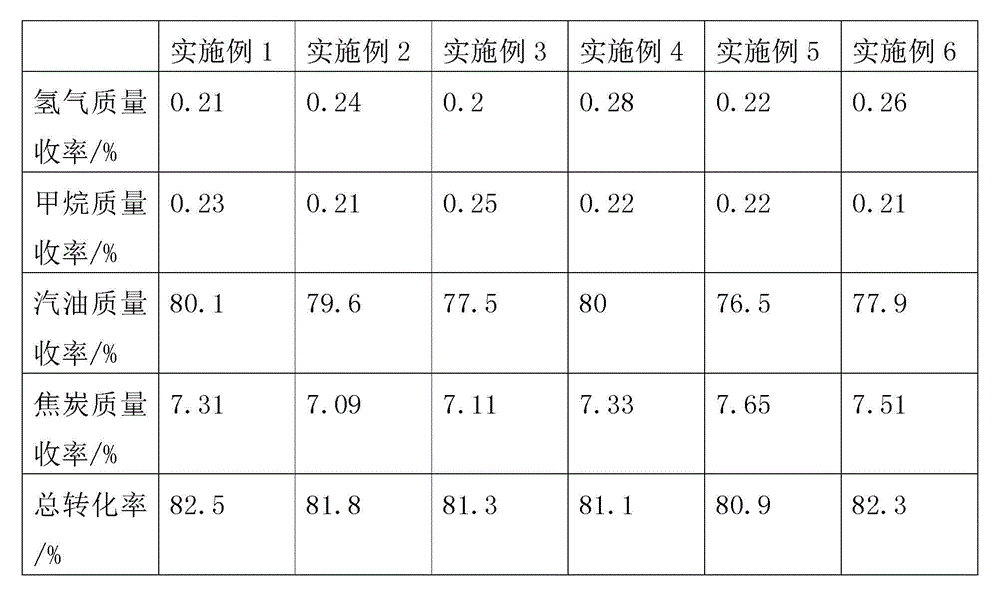

Examples

Embodiment 1

[0015] Add 170 parts of water, 8 parts of tartaric acid, 25 parts of triethylamine, 35 parts of ammonium bicarbonate, and 150 parts of antimony trioxide into the reaction kettle in sequence, stir evenly to fully dissolve it, and raise the temperature to 65-78°C at the same time, then drop Add 150 parts of hydrogen peroxide for oxidation reaction, the reaction is exothermic, the material reacts in boiling, and reflux is continuously generated, the time of dropping is 30-45 minutes, after the addition of hydrogen peroxide is completed, heat for 20-40 minutes, keep a constant temperature of 103 ° C, and finally cool and discharge , to obtain catalytic cracking metal passivation agent. The catalytic cracking metal passivator is a yellow-green clear liquid. The density (20°C) of the product measured by the method described in GB / T2504-81 is 1.26g / cm 3 ; Use the method described in GB / T265-88 to measure the kinematic viscosity of the product ≤ 4mm 2 / s; The freezing point of the p...

Embodiment 2

[0017] Add 165 parts of water, 7.2 parts of sulfonic acid, 23 parts of triethylamine, 33 parts of ammonium bicarbonate, and 140 parts of antimony trioxide into the reaction kettle in sequence, stir evenly to fully dissolve it, and raise the temperature to 65-78°C at the same time, then drop Add 155 parts of hydrogen peroxide for oxidation reaction, the reaction is exothermic, the material reacts in boiling, and reflux is continuously generated, the time of dropping is 30-45 minutes, after the addition of hydrogen peroxide is completed, heat for 20-40 minutes, keep a constant temperature of 103 ° C, and finally cool and discharge , to obtain catalytic cracking metal passivation agent. The catalytic cracking metal passivator is a yellow-green clear liquid. The density (20°C) of the product measured by the method described in GB / T2504-81 is 1.32g / cm 3 ; Use the method described in GB / T265-88 to measure the kinematic viscosity of the product ≤ 4mm 2 / s; The freezing point of the...

Embodiment 3

[0019] Add 175 parts of water, 7.8 parts of benzoic acid, 26 parts of triethylamine, 35 parts of ammonium bicarbonate, and 145 parts of antimony trioxide into the reaction kettle in sequence, stir evenly to dissolve them fully, and raise the temperature to 65-78°C at the same time, then drop Add 145 parts of hydrogen peroxide for oxidation reaction, the reaction is exothermic, the material reacts in boiling, and reflux is continuously generated, the dropwise addition time is 30-45min, after the hydrogen peroxide is added dropwise, heat for 20-40min, keep the constant temperature at 103°C, and finally cool down and discharge , to obtain catalytic cracking metal passivation agent. The catalytic cracking metal passivator is a yellow-green clear liquid. The density (20°C) of the product measured by the method described in GB / T2504-81 is 1.52g / cm 3 ; Use the method described in GB / T265-88 to measure the kinematic viscosity of the product ≤ 4mm 2 / s; The freezing point of the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com