Electro-deposition gold nanoparticles, preparation method and application thereof

A nanoparticle and electrodeposition technology, applied in the direction of material electrochemical variables, etc., can solve the problems of time-consuming preparation process and poor stability of biosensors, and achieve the effect of speeding up the rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Electrochemical method to deposit gold nanoparticles.

[0019] The self-made glassy carbon electrode (GCE) was firstly coated with 1.0, 0.3, 0.05 μm Al 2 o 3 Powder polished, ultrasonicated with water and ethanol for 5 min each, and blown dry with nitrogen. Immerse the electrode in 6 mL of 0.5 % HAuCl 4 solution (containing 0.5 M H 2 SO 4 , used N 2 Saturation for 15 minutes) and let it stand still, then use chronoamperometry to sweep at +1.1 V and 0 V for 60 s and 30 s respectively, and wash with distilled water after completion, and observe that a dark red solid appears on the surface of the glassy carbon electrode, which is Nanogold. Then put this electrode into 0.5 M H 2 SO 4 The voltammetry is used in the medium, the potential is -0.2 ~ 1.6 V and the peak current is basically unchanged (about 20 cycles) to remove the impurities adsorbed on the surface.

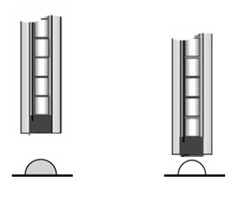

[0020] The morphology of electrodeposited gold nanoparticles is shown in figure 1 As shown,...

Embodiment 2

[0023] Example 2: Modification of GCE electrodes based on electrodeposited gold nanoparticles and magnetic iron ferric oxide nanoparticles.

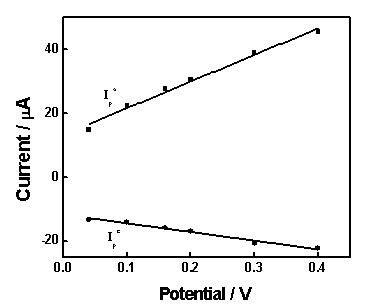

[0024] Take 20 μL of 1 mg / mL nano-ferric oxide solution with a particle size of about 10 nm on a flat glass, and use a magnetic glassy carbon electrode with nano-gold deposited to magnetically adsorb FNPs on the electrode surface. GNPs acted as nanowires in this system and were closer to the redox centers of FNPs. increase the rate of electron transfer. From image 3 It can be seen that the peak current is proportional to the scan rate, indicating that the electron transfer process is controlled by surface adsorption. And according to the Laviron equation, the electron transfer constant is 0.1s -1 .

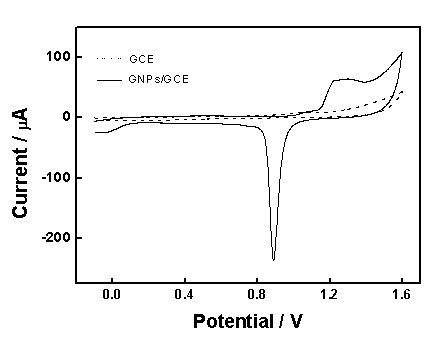

[0025] The electrochemical behavior of FNPs on the electrodeposited gold surface was investigated by cyclic voltammetry, as shown in Figure 4 As shown, by comparison, it can be seen that FNPs have no obvious redox peaks on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com