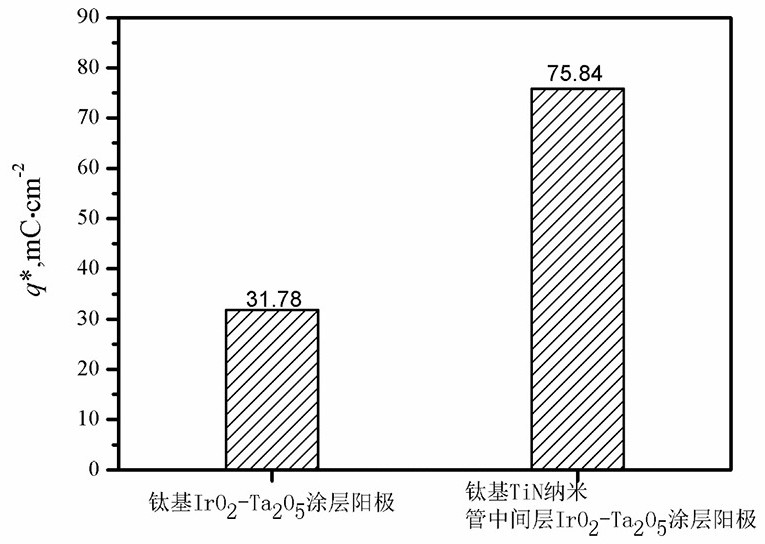

IrO2-Ta2O5 anode with TiN nanotube middle layer

An iro2-ta2o5, nanotube technology, applied in electrodes, coatings, surface reaction electrolytic coatings, etc., can solve the problems of reduced electrode life, low electrocatalytic activity of the coating anode, low heat generation, etc., and achieves excellent performance and low preparation cost. , combined with a strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

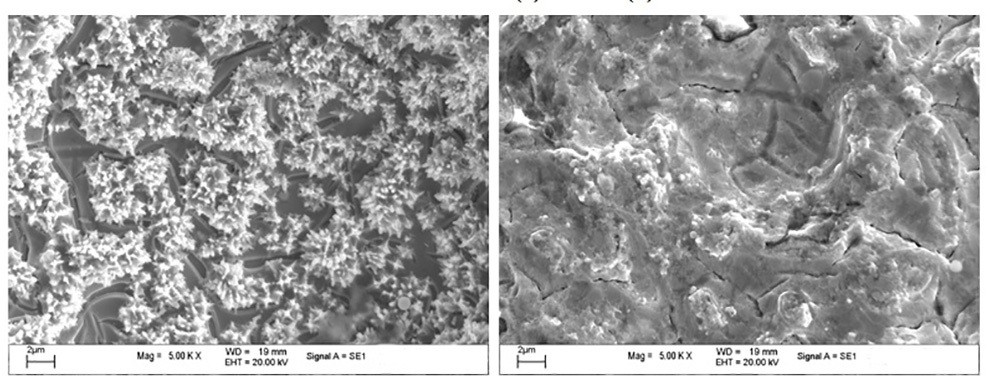

[0048] The IrO with TiN nanotube interlayer provided by the present embodiment 2 -Ta 2 o 5 Nano-coated anode material, with Ti as the substrate (specifically TA2 titanium), and IrO on the surface 2 -Ta 2 o 5 nanocoating while IrO 2 -Ta 2 o 5 An intermediate layer of TiN nanotubes is prepared between the nano-coating and the Ti substrate; the specific preparation steps are described as follows.

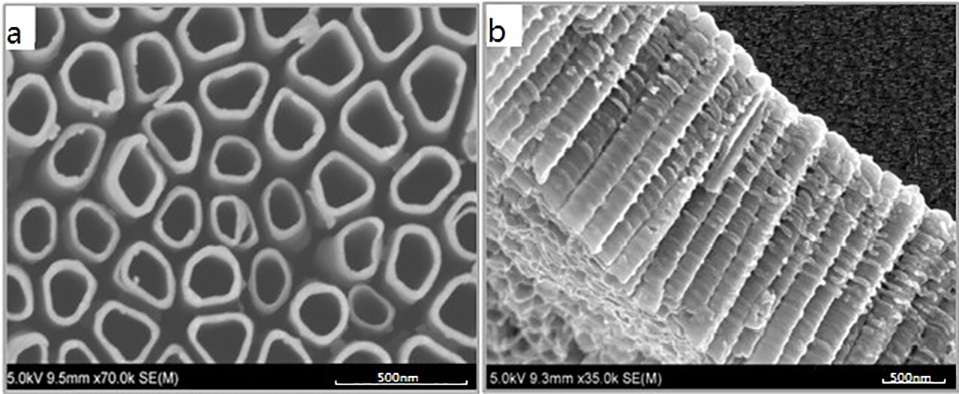

[0049] (1) Preparation of TiO 2 nanotube

[0050] First, the titanium substrate is polished, and then the anodic oxidation method is used to prepare and form TiO on the surface of the titanium substrate. 2 nanotube layer; when prepared, will contain TiO 2 The titanium substrate of the nanotube layer is alternately rinsed with deionized water and ethanol and ultrasonically treated to remove the electrolyte and debris remaining on the surface, rinsed and dried in a nitrogen flow for later use;

[0051] Preparation of TiO by anodic oxidation 2 For the nanotube layer, the refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com