Preparation method of Sb-based ductile carbon composite negative electrode material

A negative electrode material and ductile technology, which is applied in the field of preparation of antimony/ductile carbon composite negative electrode materials, can solve the problems of limited electrode cycle stability, shorten the diffusion and migration distance, increase stability, and buffer volume expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

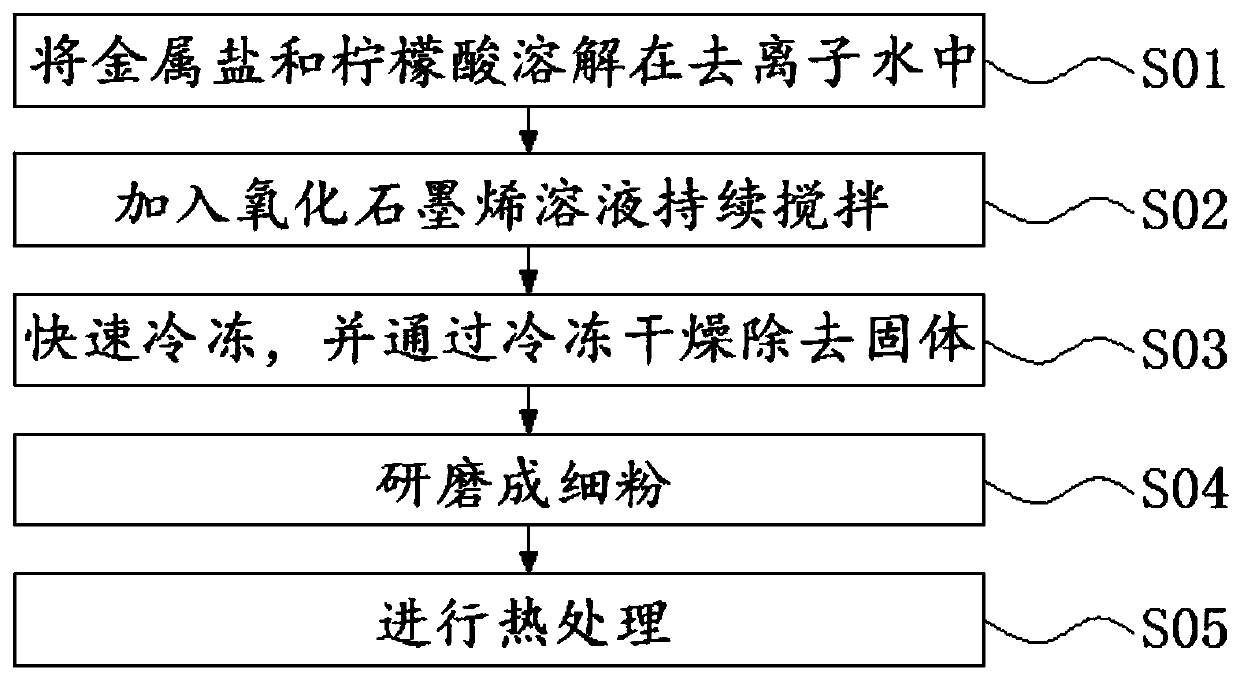

[0027] refer to figure 1 , a preparation method of antimony / ductile carbon composite negative electrode material, said method comprising the steps of:

[0028] S01, metal salt and citric acid are dissolved in deionized water, obtain uniform transparent solution, and described metal salt is antimony chloride (SbCl );

[0029] S02, adding the graphene oxide solution into the transparent solution, and continuously stirring, the continuous stirring time is 20-90min, to obtain a uniform mixed solution;

[0030] S03, the mixed solution is quickly frozen, and the solid is removed by freeze-drying to obtain a spongy sample;

[0031] S04, grinding the spongy sample into a fine powder to obtain a mixed powder;

[0032] S05. Carry out heat treatment to the composite powder, the heat treatment process: put the composite powder into a quartz boat, then place the quartz boat in a tube furnace, and then in a hydrogen and argon atmosphere, the volume of the hydrogen and argon The ratio is ...

Embodiment 1

[0035] like figure 1 As shown, first S01, antimony chloride (SbCl 3 ) and citric acid were dissolved in deionized water to obtain a uniform transparent solution;

[0036] Then S02, graphene oxide (GO) solution is added in above-mentioned homogeneous transparent solution, and continuous stirring 30min, obtains uniform mixed solution;

[0037] Then S03, the mixed solution is snap-frozen, and the solid is removed by freeze-drying to obtain a spongy sample;

[0038] S04 grinds the spongy sample into a fine powder again to obtain a mixed powder;

[0039] Finally S05 heat-treats the resulting mixed powder, that is, the composite powder is put into a quartz boat, and then the quartz boat is placed in a tube furnace, and then heated in hydrogen (H 2 ) and argon (Ar) atmosphere (V / V=10 / 90), at 5°C min -1 The heating rate was increased to 650°C, and the temperature was maintained for 3 hours to obtain an antimony / ductile carbon composite negative electrode material.

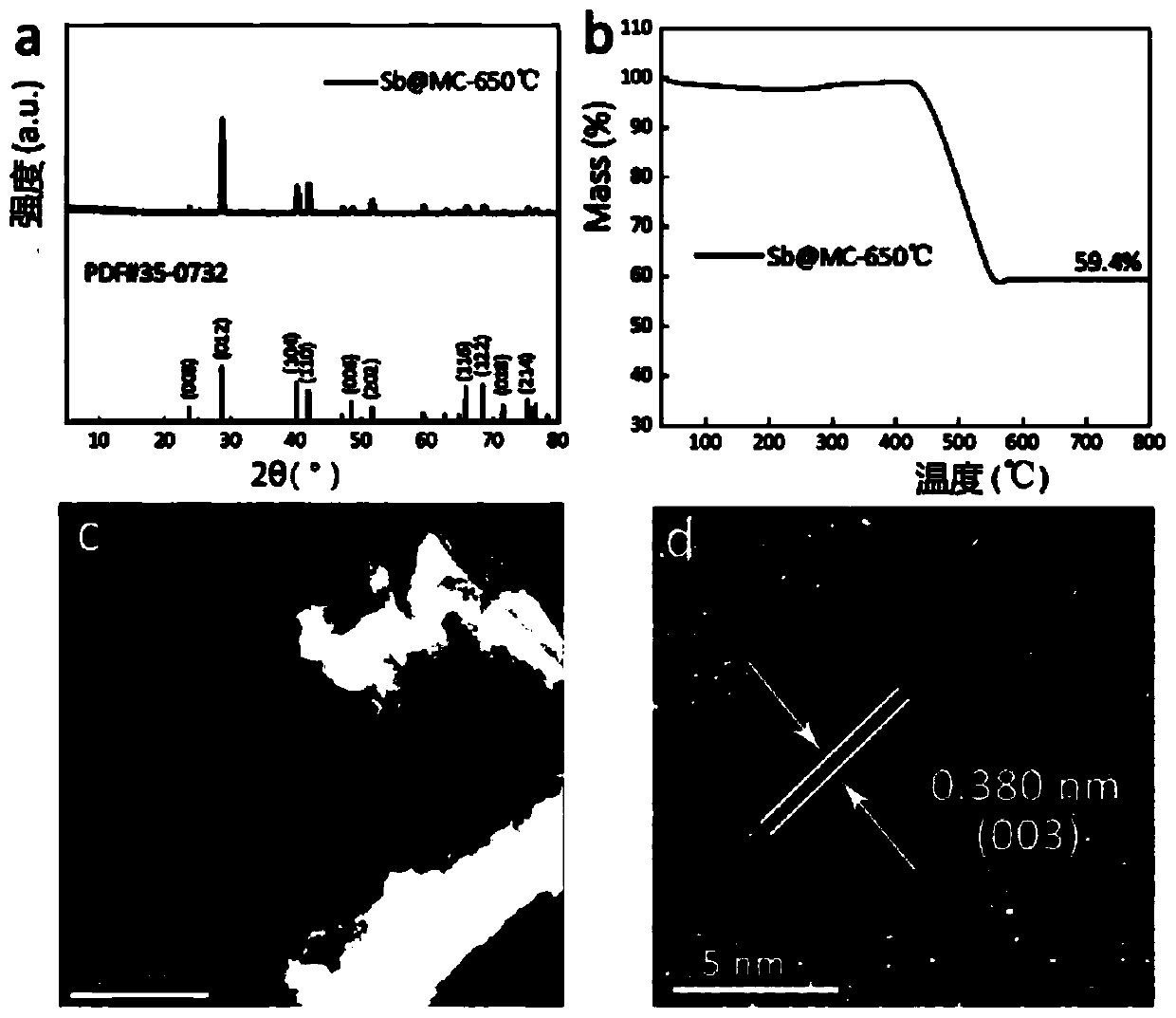

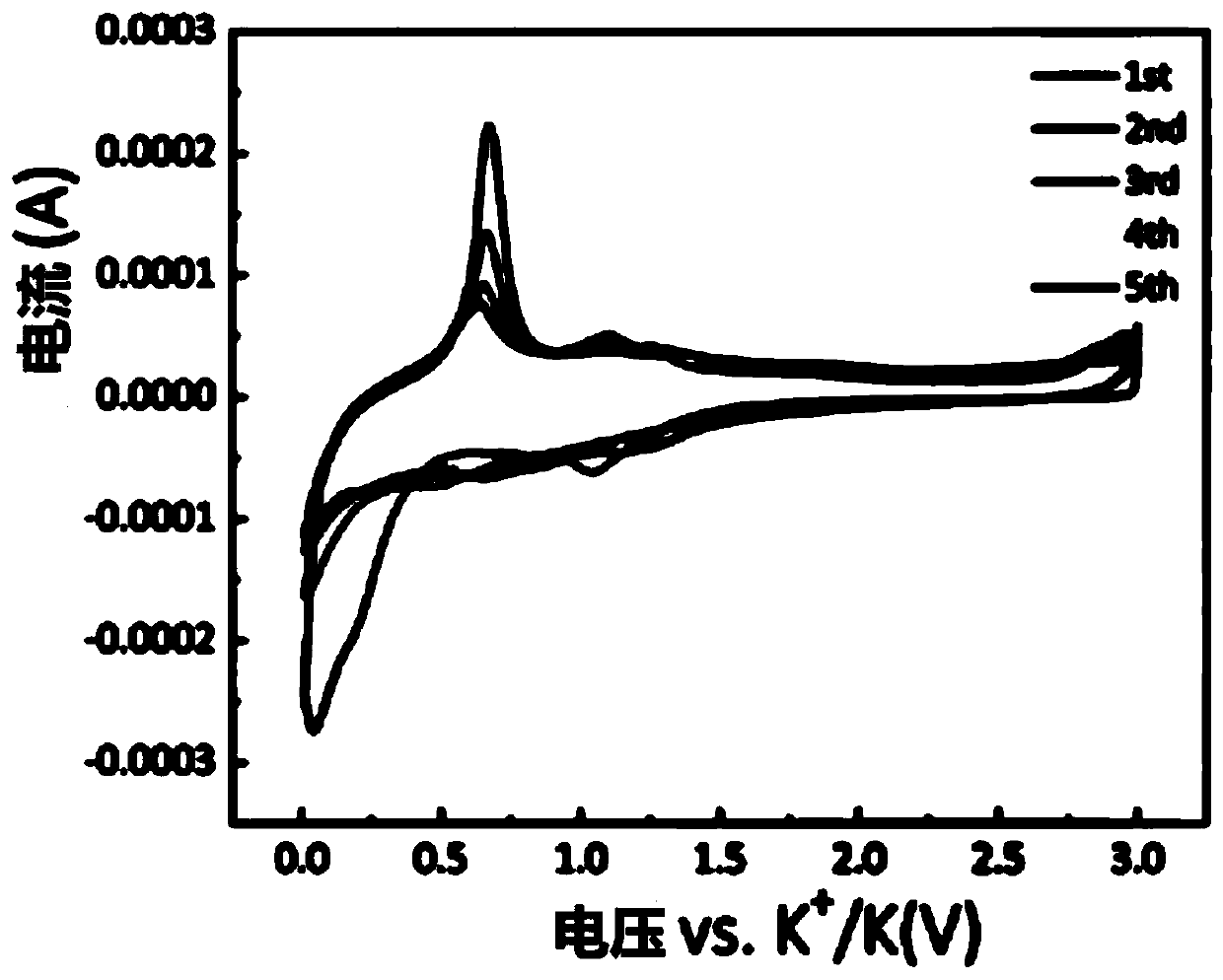

[0040] like ...

Embodiment 2

[0045] First, antimony chloride (SbCl 3 ) and citric acid were dissolved in deionized water to obtain a uniform transparent solution;

[0046] Next, the graphene oxide (GO) solution was added to the above-mentioned uniform transparent solution, and continued to stir for 60 minutes to obtain a uniform mixed solution;

[0047] Then, the mixed solution was snap-frozen, and the solids were removed by freeze-drying to obtain a sponge-like sample;

[0048] Then the sponge sample is ground into a fine powder to obtain a mixed powder;

[0049] Finally, the resulting mixed powder is heat-treated, that is, the composite powder is put into a quartz boat, and then the quartz boat is placed in a tube furnace, and then heated in hydrogen (H 2 ) and argon (Ar) atmosphere (V / V=10 / 90), at 4°C min -1 The heating rate was increased to 600°C, and the temperature was maintained for 5 hours to obtain an antimony / ductile carbon composite negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com