Micro-nano structure bismuth pole for trace heavy metal detection and preparation method thereof

A technology of trace heavy metals and micro-nano structure, applied in the direction of material electrochemical variables, etc., can solve the problems of poor reproducibility, unfavorable detection of trace heavy metals, and low detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

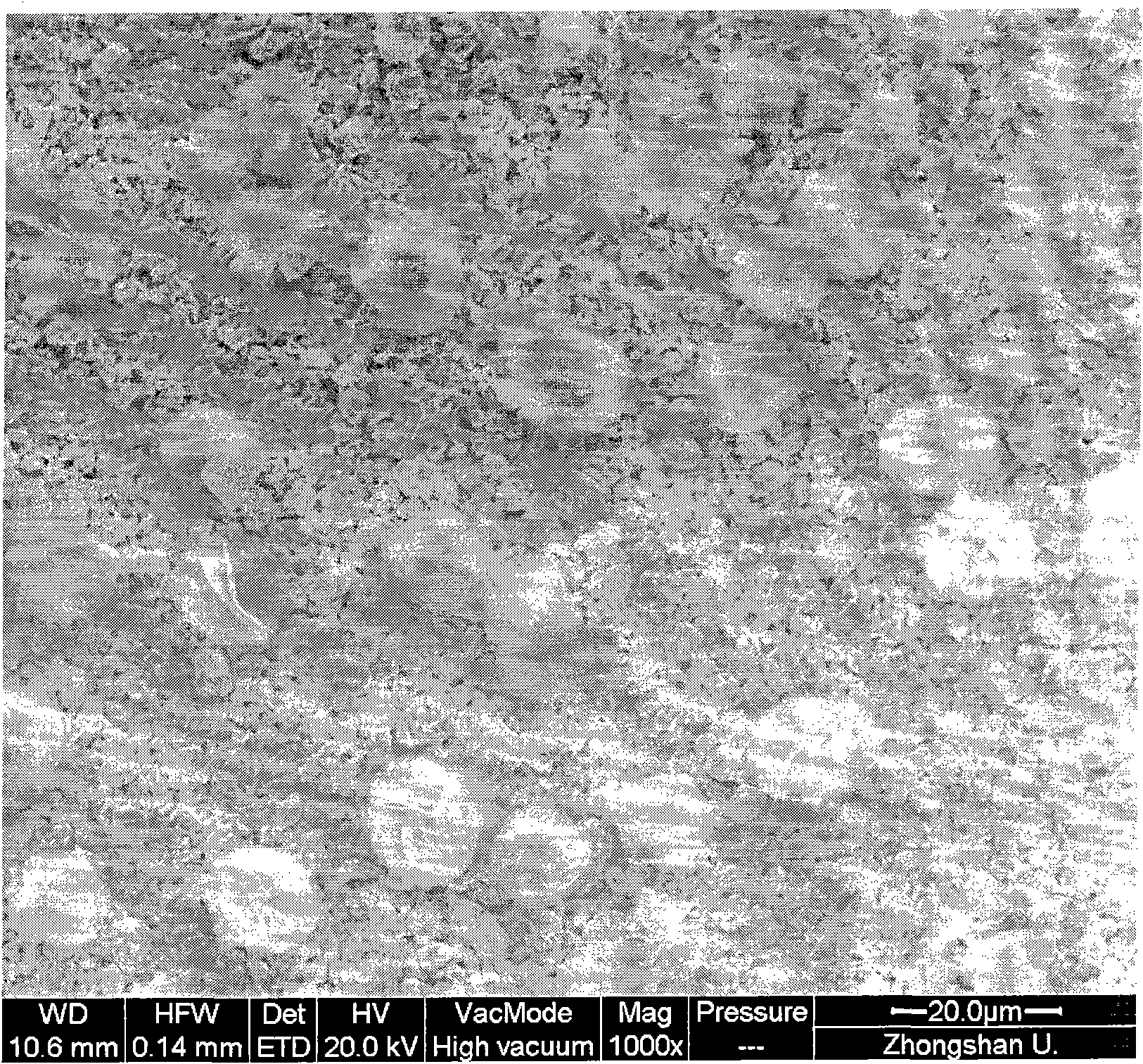

Image

Examples

Embodiment 1

[0019] Copper foil is used as the working electrode to prepare the bismuth electrode of the two-dimensional bismuth micro-nano structure array. The thickness of the copper foil is 0.5mm, and the area is about 10×10mm 2 . Its preparation method comprises the following steps:

[0020] (1) Before depositing, a series of pretreatments should be carried out on the copper foil: first, the copper foil should be polished with metallographic sandpaper and abrasive paste to make the surface of the copper foil smooth and flat. The copper foil is ultrasonically assisted to remove the grease that may remain on the surface of the copper foil. Finally, it is rinsed with deionized water, dried with cold air, and stored for later use in depositing a thin film.

[0021] (2) Deposition of two-dimensional bismuth nanosheet arrays by constant potential method, the deposition potential is -0.15V (vs. SCE), the deposition time is 1500s, and the various chemical components in the electrolyte are: Bi...

Embodiment 2

[0024] Copper foil is used as the working electrode to prepare the bismuth electrode of the two-dimensional bismuth micro-nano structure array. The thickness of the copper foil is 0.5mm, and the area is about 10×10mm 2 . Its preparation method comprises the following steps:

[0025] (1) Before depositing, a series of pretreatments should be carried out on the copper foil: first, the copper foil should be polished with metallographic sandpaper and abrasive paste to make the surface of the copper foil smooth and flat. The copper foil is ultrasonically assisted to remove the grease that may remain on the surface of the copper foil. Finally, it is rinsed with deionized water, dried with cold air, and stored for later use in depositing a thin film.

[0026] (2) Deposition of two-dimensional bismuth nanosheet arrays by constant potential method, the deposition potential is -0.12V (vs. SCE), the deposition time is 1000s, and the various chemical components in the electrolyte are: Bi...

Embodiment 3

[0029] Using nickel foil as the working electrode to prepare the bismuth electrode of the two-dimensional bismuth micro-nano structure array, the thickness of the nickel foil is 0.5mm, and the area is about 10×10mm 2 . Its preparation method comprises the following steps:

[0030] (1) Before deposition, a series of pretreatments should be carried out on the nickel foil: first, the nickel foil should be polished with metallographic sandpaper and abrasive paste to make the surface of the nickel foil smooth and flat, and then polished with acetone and alcohol in sequence The nickel foil is ultrasonically assisted to remove the grease that may remain on the surface of the nickel foil, and finally rinsed with deionized water, dried with cold wind, and stored for future use in depositing thin films.

[0031] (2) Deposition of two-dimensional bismuth nanosheet arrays by constant potential method, the deposition potential is -0.18V (vs. SCE), the deposition time is 1000s, BiCl 3 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com