Zinc negative electrode material of zinc air cell and preparation method for zinc negative electrode material

A zinc-air battery and zinc negative electrode technology, which is applied to battery electrodes, fuel cell-type half-cells, secondary battery-type half-cells, circuits, etc., can solve the problem of electrode porosity and reaction specific surface area reduction, and can not solve the problem of zinc The problem of densification of powder electrodes, improvement of battery discharge capacity and rate performance, etc., achieve high hydrophilicity and insulation, increase liquid storage rate and water delivery performance, and improve discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

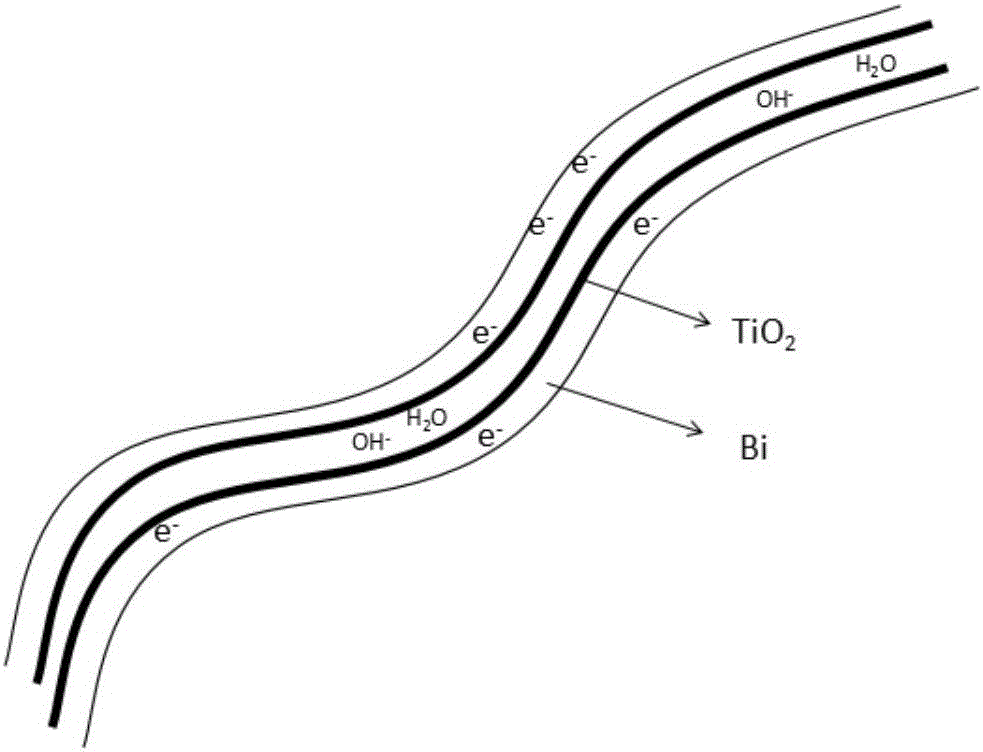

[0032] Bifunctional additive: inner diameter 50nm, titanium dioxide layer thickness 8nm, bismuth oxide layer thickness 100nm, length 45μm.

[0033] Percentage by weight: metal zinc powder 5%, zinc oxide powder 80%, bifunctional additive 7%, conductive carbon black 5%, polytetrafluoroethylene 3%.

[0034] Preparation of zinc anode material: Prepare 10 mL of absolute ethanol, add 4d polytetrafluoroethylene 60% suspension, and stir magnetically for 20 min. Weigh a certain amount of metal zinc powder, zinc oxide powder, bifunctional additives, and conductive carbon black according to the above ratio, and add them to the ethanol solution containing polytetrafluoroethylene in sequence, and then continue to stir for 30 minutes. Continue to stir the dispersed solution at a stirring speed of 600 rpm, and set the evaporation temperature of the dispersant at 60° C., and obtain the negative electrode slurry after 10 minutes.

[0035] The slurry was evenly coated on a 2cm×2cm brass mesh, ...

Embodiment 2

[0038] Bifunctional additive A: inner diameter 50nm, titanium dioxide layer thickness 12nm, chromium oxide layer thickness 200nm, length 23μm;

[0039] Bifunctional additive B: inner diameter 50nm, titanium dioxide layer thickness 10nm, lead dioxide layer thickness 180nm, length 23μm.

[0040] Percentage by weight: 10% of metal zinc powder, 76% of zinc oxide powder, 2% of bifunctional additive A, 2% of bifunctional additive B, 5% of conductive carbon black, and 5% of polyvinyl alcohol.

[0041] Preparation of zinc anode material: Prepare 15 mL of acetone, add 0.0588 g of polyvinyl alcohol, and stir magnetically for 30 min. Weigh a certain amount of metal zinc powder, zinc oxide powder, bifunctional additives A and B, and conductive carbon black according to the above ratio, and add them to the acetone solution containing polyvinyl alcohol in sequence, and then continue to stir for 30 minutes. Continue to stir the dispersed solution at a stirring speed of 2000 rpm, and set the...

Embodiment 3

[0045] Bifunctional additive: inner diameter 100nm, titanium dioxide layer thickness 4nm, bismuth oxide layer thickness 300nm, length 14μm.

[0046] Percentage by weight: 10% of metal zinc powder, 78% of zinc oxide powder, 2% of bifunctional additive, 5% of acetylene black, and 5% of polytetrafluoroethylene.

[0047] Preparation of zinc anode material: prepare 13 mL of deionized water, add 3d polytetrafluoroethylene 60% suspension, and stir magnetically for 30 min. Weigh a certain amount of metal zinc powder, zinc oxide powder, bifunctional additives, and acetylene black according to the above ratio, and add them to the dispersion containing polytetrafluoroethylene in sequence, and then continue to stir for 30 minutes. Continue to stir the dispersed solution at a stirring speed of 2000 rpm, and set the evaporation temperature of the dispersant to 75° C., and obtain the negative electrode slurry after 21 minutes.

[0048] The slurry was uniformly coated on a 2cm×2cm brass mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com