Solid oxide fuel cell composite electrolyte film and preparation thereof

A composite electrolyte and electrolyte film technology, applied in the field of solid oxide fuel cells, can solve the problems of easy occurrence of harmful chemical reactions, low oxygen ion conductivity, and large battery ohmic resistance, so as to improve long-term stability and reliability, improve The effect of high output performance and open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

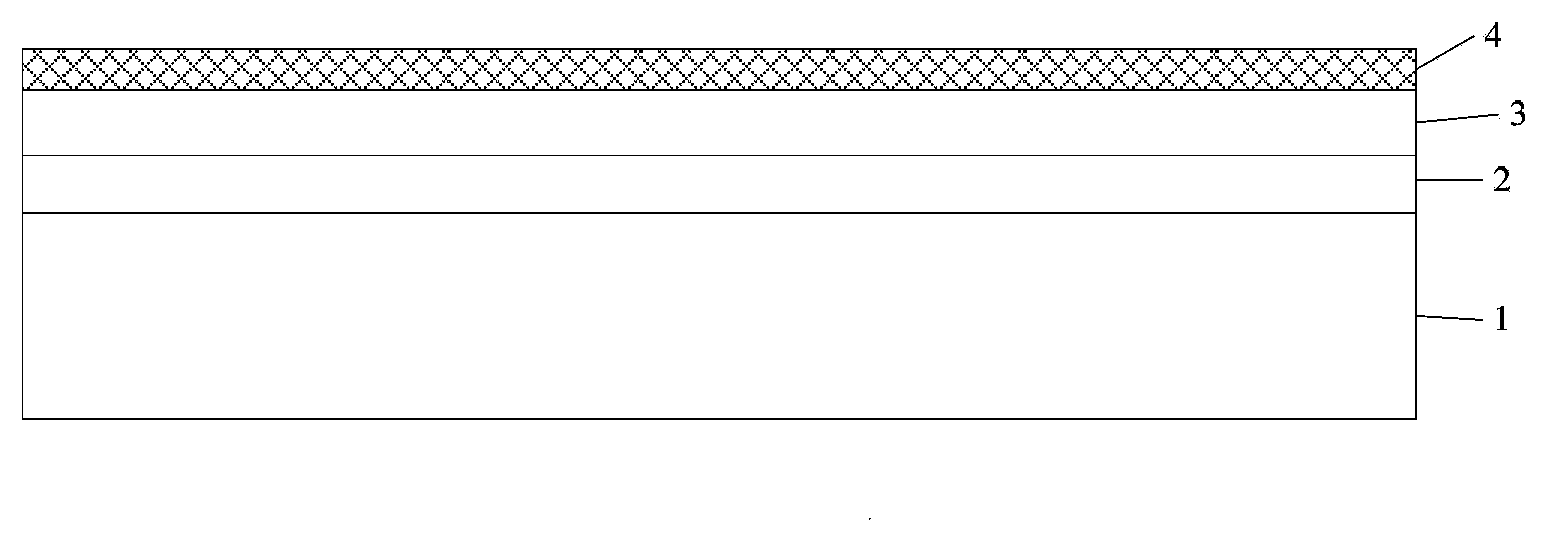

Image

Examples

Embodiment 1

[0033] In nickel oxide with Y 2 o 3 Stable ZrO 2 Sputtering Dense Y on Composite Anode Substrate 2 o 3 Doped ZrO 2 (Y 0.08 Zr 0.92 o 2 ) Electrolyte film, after cleaning the anode substrate ultrasonically with acetone, ethanol, and distilled water and drying it, put it into the vacuum chamber of the magnetron sputtering instrument, adjust the target base distance to about 6cm, and use yttrium / zirconium alloy material as Target material, the purity of the target material is above 99.99%, the molar ratio of yttrium / zirconium is 8 / 92, and the vacuum is 8*10 -4 Pa, then turn on the substrate table to heat, the temperature rises to 400°C, the flow rate of argon gas is 10.0 sccm, the flow rate of oxygen is 1.0 sccm, and the sputtering power is 10W / cm 2 , the sputtering air pressure is 0.5Pa, the rotation speed of the substrate table is set at 5 cycles / min, and the thickness is about 1 μm. 0.08 Zr 0.92 o 2 After sputtering, anneal at 1200°C for 2 hours in the air atmospher...

Embodiment 2

[0036] In nickel oxide with Y 2 o 3 Stable ZrO 2 Sputtering Dense Y on Composite Anode Substrate 2 o 3 Doped ZrO 2 (Y 0.08 Zr 0.92 o 2 ) Electrolyte film, after cleaning the anode substrate ultrasonically with acetone, ethanol, and distilled water and drying it, put it into the vacuum chamber of the magnetron sputtering instrument, adjust the target base distance to about 7cm, and use yttrium / zirconium alloy material as Target material, the purity of the target material is above 99.99%, the molar ratio of yttrium / zirconium is 8 / 92, and the vacuum is 8*10 -4 Pa, then turn on the substrate table to heat, the temperature rises to 800°C, the flow ratio of oxygen and argon is 1 / 5, and the sputtering power is 12W / cm 2 , the sputtering pressure is 0.3Pa, the rotation speed of the substrate table is set to 8 cycles / min, the thickness is about 0.8μm, and the dense Y 0.08 Zr 0.92 o 2 After sputtering, replace the yttrium / zirconium alloy target with a cerium / samarium alloy tar...

Embodiment 3

[0039] In nickel oxide with Y 2 o 3 Stable ZrO 2 Sputtering Dense 10mol%Sc on Composite Anode Substrate 2 o 3 with 1mol%CeO 2 Co-doped ZrO 2 (Ce 0.01 sc 0.1 Zr 0.89 o 2 ) Electrolyte film, after cleaning the anode substrate ultrasonically with acetone, ethanol, and distilled water and drying it, put it into the vacuum chamber of the magnetron sputtering instrument, adjust the target base distance to about 7cm, use scandium / cerium / zirconium alloy The material is a target, the purity of the target is above 99.99%, the molar ratio of scandium / cerium / zirconium is 10 / 1 / 89, and the vacuum is 8*10 -4 Pa, then turn on the substrate table to heat, the temperature rises to 600°C, the flow ratio of oxygen and argon is 1 / 8, and the sputtering power is 9W / cm 2 , the sputtering pressure is 0.5Pa, the rotation speed of the substrate stage is set to 6 cycles / min, the thickness is about 0.8μm, and the dense Ce 0.01 sc 0.1 Zr 0.89 o 2 After the sputtering of , replace the Ce / Gd (9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com