A weld

A welding seam and micro-welding seam technology, applied in laser welding equipment, welding equipment, thin plate connection, etc., can solve the problems of unreliable laser seam, hard and brittle laser seam, undesired and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

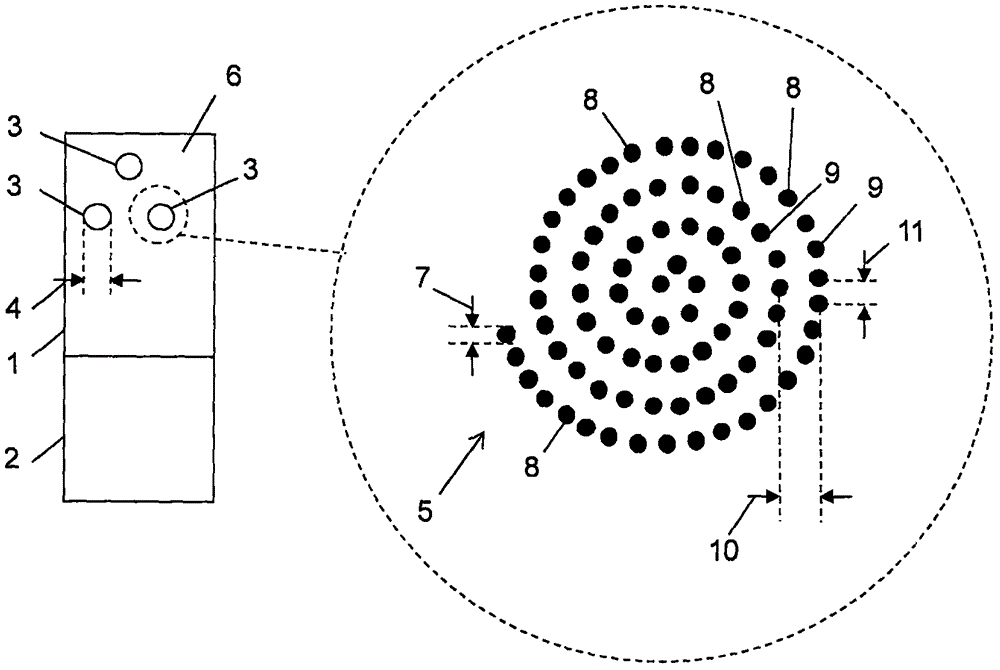

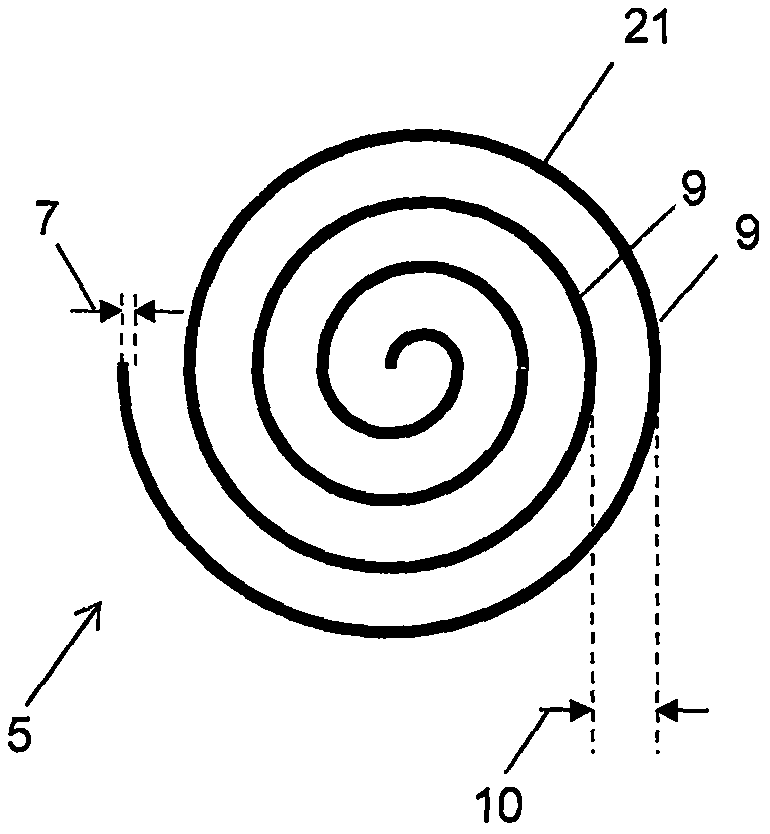

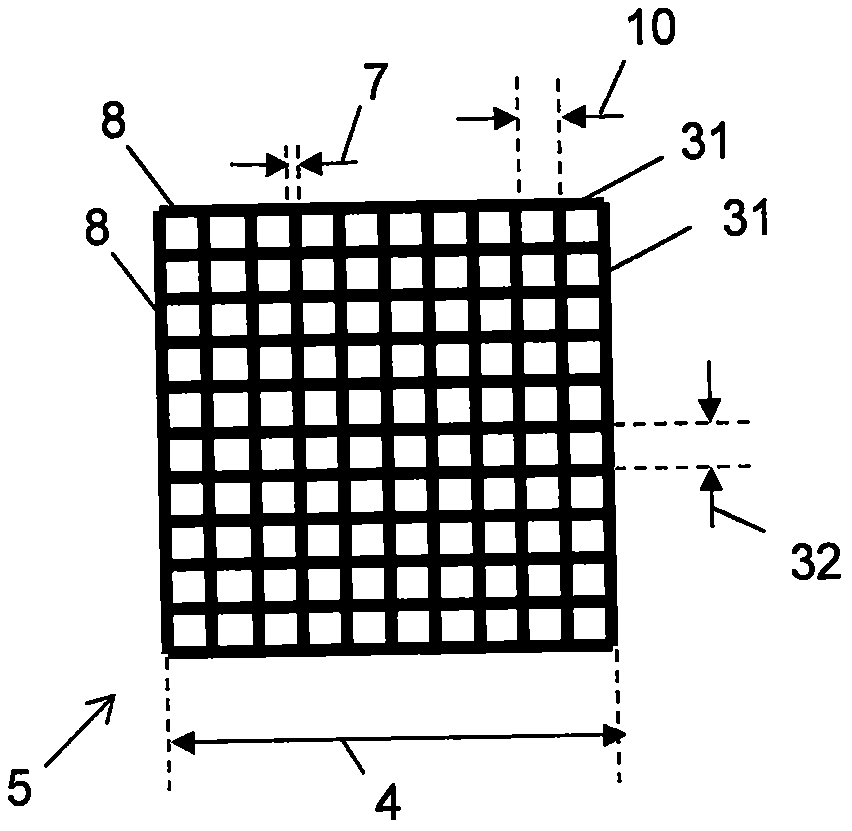

[0061] Figure 15 Shown is a cross-section of an artistically processed weld 150 formed between copper having a thickness 151 of 100 μm and aluminum having a thickness 152 of 400 μm. Weld seam 150 is spiral type, as figure 2 As shown, the first spacing 10 between the helical arms is 50 μm and the diameter 4 is 1 mm. The width 74 of the hole 71 is approximately 5 μm to 20 μm. The weld seam is formed using multiple pulses from the laser 61 overlapping each other on the first material 1 with an area of 95%-98%. The laser 61 cuts the first material 1 copper and the second material 2 (aluminum) flows into the hole 71 . At least a portion of the first material 1 is impregnated into the second material 2 , as seen in the region 121 comprising the first material 1 . The region 121 extends approximately 300 μm-400 μm into the second material 2 . Voids 122 also appear. A triangular-like heat-affected zone 155 , shown in dashed lines, appears below the aperture 71 . Only one he...

example 2

[0066] Figure 17 A cross-section of a weld 170 formed between a first material 1 copper and a second material 2 brass is shown. Weld 170 can also be formed as Figure 13The quasi-spiral pattern of the weld shown. Surprisingly, the brass has flowed into the copper material, forming a weld 170 with very little intermetallic mixing. The weld 170 is substantially non-uniform. (missing sentence) Copper and brass flow but do not mix together to form a new homogeneous material phase. The material phases of copper and brass are largely unmixed, and both copper and brass are primary material phases. Especially surprising is that brass is an alloy of copper and zinc. Inside the second material 2 there is some first material 1 . These are also voids 122 . The final joint formed by weld 170 has good shear strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com