Preparation method of anode supporter of tube-type solid-oxide fuel battery

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, fuel cell components, fuel cells, etc., to achieve the effects of improving output characteristics, good output performance, and reducing ohmic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

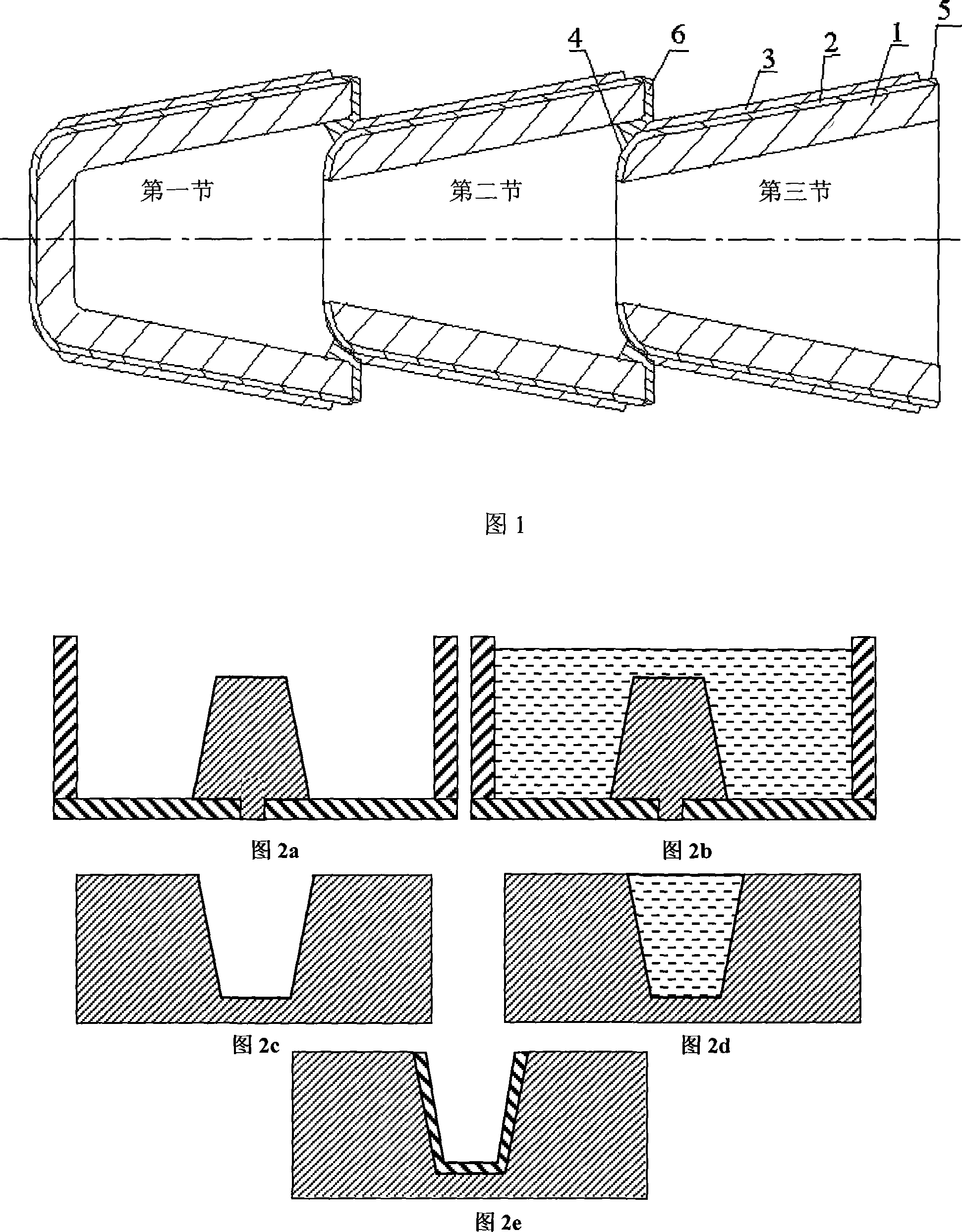

[0024] When the porous anode support body 1 is prepared by the plaster mold grouting method. In the first step, the gypsum mold is prepared by the cylindrical aluminum alloy mold shown in Figure 2a. The specific process is as follows: bake the anhydrous gypsum powder at 150°C for 5 hours, cool to room temperature and set aside; put the baked gypsum Mix the powder with water of equal mass and stir evenly to obtain gypsum slurry; quickly pour the gypsum slurry into the cylindrical metal mold shown in Figure 2a, after 30 minutes the gypsum solidifies, and the metal mold is removed to obtain the gypsum slurry shown in Figure 2c. A plaster mold for grouting the anode support tube as shown;

[0025] The second step is to inject the anode slurry into the plaster mold to obtain the anode support body. The specific process is as follows:

[0026] (1) Anode powder is obtained after uniformly mixing NiO and YSZ powders of equal mass; adding 85wt% water to the anode powder, and planetary...

Embodiment 2

[0029] When the porous anode support body 1 is prepared by the plaster mold grouting method. In the first step, the gypsum mold is prepared by the cylindrical aluminum alloy mold shown in Figure 2a. The specific process is as follows: bake the anhydrous gypsum powder at 160°C for 4 hours, and cool it to room temperature for use; Mix the powder with water of equal mass and stir evenly to obtain a gypsum slurry. Use a straw to add 3-5 drops of pyridine as a defoamer; as shown in Figure 2, quickly pour the gypsum slurry into the cylindrical metal as shown in Figure 2a In the mould, after 30 minutes, the gypsum is solidified, and the metal mold is removed to obtain the gypsum mold for grouting the anode support tube as shown in Figure 2c;

[0030] The second step is to inject the anode slurry into the plaster mold to obtain the anode support body. The specific process is as follows:

[0031] (1) The anode powder is obtained by uniformly mixing the equal mass of NiO and YSZ powder...

Embodiment 3

[0034]When the porous anode support body 1 is prepared by the plaster mold grouting method. In the first step, the gypsum mold is prepared by the cylindrical aluminum alloy mold shown in Figure 2a. The specific process is as follows: bake the anhydrous gypsum powder at 170°C for 3 hours, and cool it to room temperature for use; Mix the powder with water of equal mass, and stir evenly to obtain a gypsum slurry. Use a straw to add 3-5 drops of absolute alcohol as a defoamer; quickly pour the gypsum slurry into the cylindrical metal mold shown in Figure 2a, 30 Minutes later, the gypsum is solidified, and the metal mold is sloughed off to obtain the gypsum mold for grouting the anode support tube as shown in Figure 2c;

[0035] The second step is to inject the anode slurry into the plaster mold to obtain the anode support body. The specific process is as follows:

[0036] (1) Anode powder is obtained after uniformly mixing NiO and YSZ powders of equal mass; adding 45wt% water to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com