Pipe type lifting-flow air cathode microbiological fuel cell

An air cathode and fuel cell technology, applied in the field of electrochemical energy, to achieve the effects of reducing basic cost, reducing ohmic internal resistance and activation internal resistance, and improving processing capacity and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

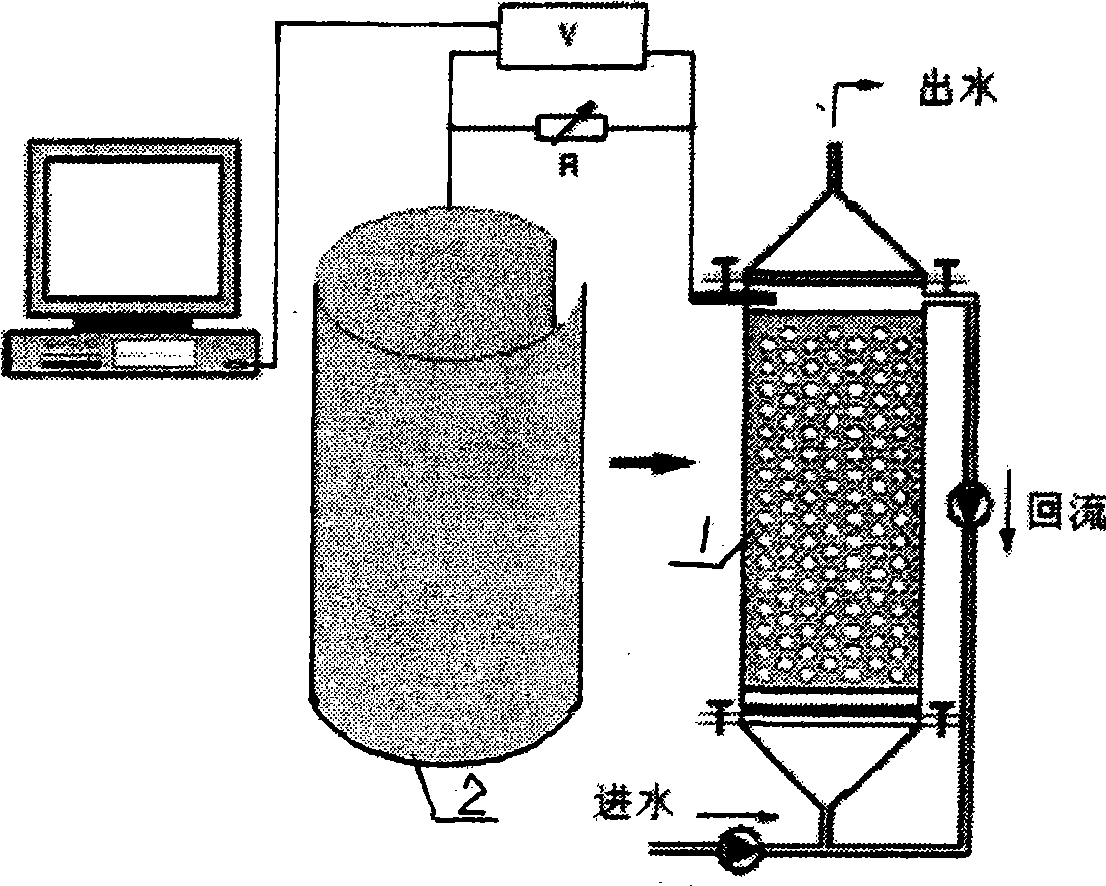

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0027] combine Figure 1-Figure 3 , In the present embodiment, the tubular upflow air cathode microbial fuel cell (TUAMFC) consists of a cylindrical plexiglass tube with a diameter of 3 cm and a height of 13.5 cm, with a wall thickness of 0.2 cm and a total volume of 95 mL. A feed inlet is set at the bottom of the battery, and a water outlet is set at the top. Small holes with a diameter of 2.0mm are evenly drilled on the tube wall of the anode area, and the protons are transmitted through these holes. The total area of the holes is 60cm 2 . The tube is filled with granular activated carbon (diameter 3mm ~ 5mm) as the battery anode. The solution volume in the anode zone was 55 mL. The anode 1 is inserted into a carbon rod (diameter 1 cm, length 5 cm) to export electrons. Cathode 2 is made of carbon cloth (30% waterproof treatment, 10cm * 10cm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com