Cr2O3 doped silicon dioxide aerogel material and preparation method thereof

A silica and aerogel technology, which is applied in the field of Cr2O3 doped silica aerogel material and its preparation, can solve the problems of uneven distribution of doping ions, influence on thermal insulation stability, uneven distribution, etc. The effect of uniform dispersion, improved thermal insulation performance and stability, and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

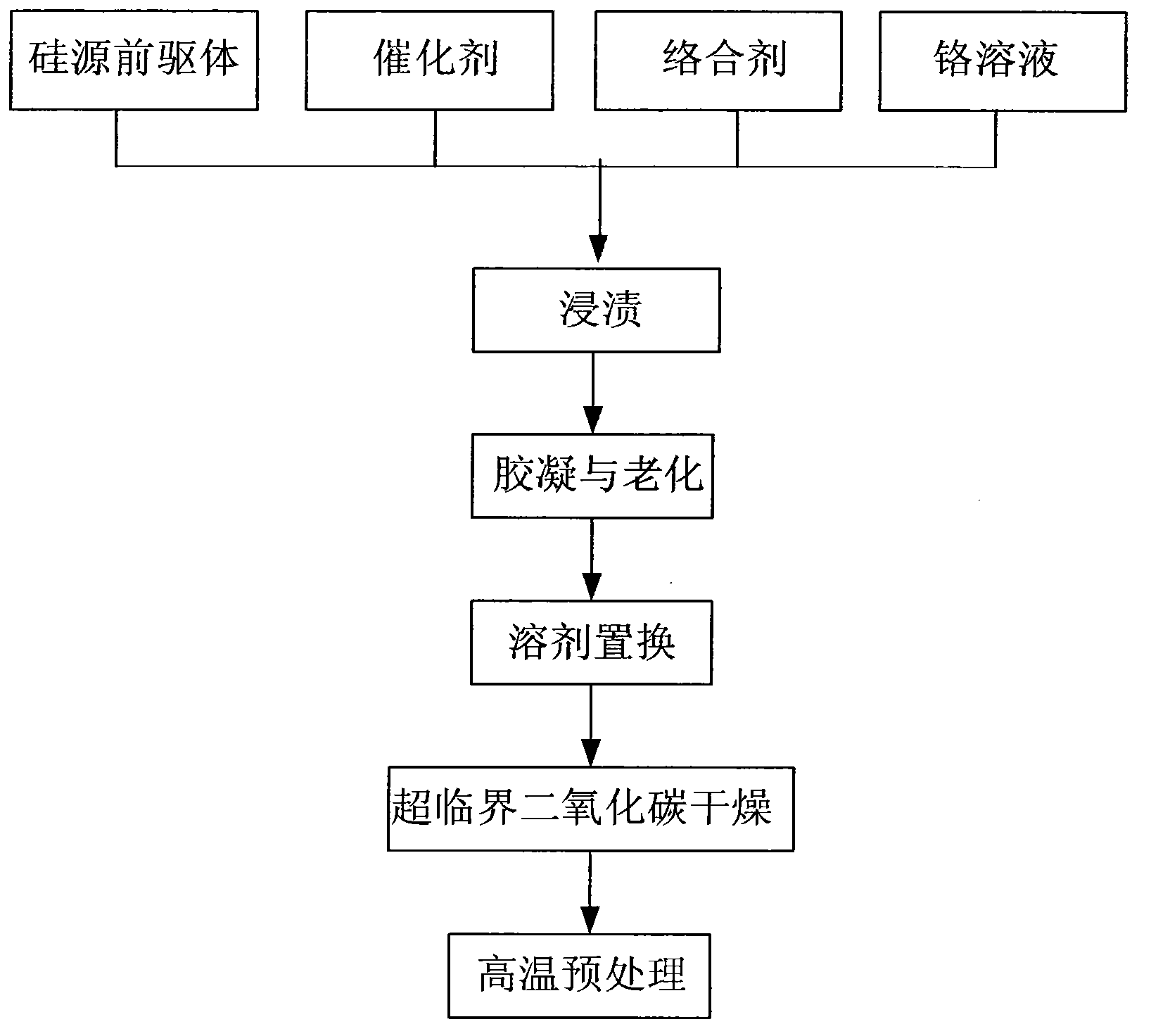

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of composite sol

[0041] Silica water sol, chromium chloride aqueous solution, and complexing agent are mixed in a molar ratio of 1:0.05:0.08, and an acid-base catalyst is added to form a composite sol.

[0042] (2) Dipping

[0043] Add the sol to a bulk density of 0.08g / cm 3 The mold of the mullite fiber felt relies on gravity impregnation.

[0044] (3) Gel and Aging

[0045] The mold was placed at 25° C. for 8 hours to form a gel, and then placed at 50° C. for 72 hours. After the mold was naturally cooled to room temperature, the mold was removed to obtain a fiber-reinforced wet gel.

[0046] (4) Solvent replacement

[0047] The wet gel is placed in absolute ethanol so that the water content is lower than 1% (mass ratio).

[0048] (5) Supercritical drying

[0049] Put the wet gel into the autoclave, inject 5MPa carbon dioxide, and keep it warm at 40°C for 15 hours; then raise the temperature to 50°C, and the carbon dioxide will bring the ethanol i...

Embodiment 2

[0054] The silicon dioxide hydrosol, the chromium acetate aqueous solution, and the complexing agent are mixed in a molar ratio of 1:0.10:0.08, and an acid-base catalyst is added to form a composite sol. Pre-impregnated with sol with a bulk density of 0.08g / cm 3 The quartz fiber felt is then loaded into the mold cavity, added with sol, and impregnated by pressure. The mold was placed at 40°C for 24 hours to form a gel, and then placed at 60°C for 48 hours. After the mold was naturally cooled to room temperature, the mold was removed to obtain a fiber-reinforced wet gel. The wet gel is placed in ethanol so that the water content is lower than 1% (mass ratio). Carry out supercritical drying according to the method described in Example 1. The obtained fiber-reinforced airgel insulation material was subjected to high-temperature pretreatment under the air condition of 800°C, the heating rate was 8°C / min, and the holding time was 2 hours. After high-temperature pretreatment, Cr ...

Embodiment 3

[0057] Methyl orthosilicate, chromium sulfate alcohol solution, and complexing agent are mixed in a molar ratio of 1:0.25:0.10, and a catalyst is added to form a composite sol. Directly pass the sol through a vacuum device and inject it into a device with a bulk density of 0.50g / cm 3 The glass fiber wool is impregnated in the mold cavity. The mold was placed at 40°C for 10 hours to form a gel, and then placed at 80°C for 96 hours. After the mold was naturally cooled to room temperature, the mold was removed to obtain a fiber-reinforced wet gel. The wet gel is placed in propanol so that the water content is lower than 1% (mass ratio). Carry out supercritical drying according to the method described in Example 1. The obtained fiber-reinforced airgel thermal insulation material is subjected to high-temperature pretreatment under the air condition of 600°C, the heating rate is 3°C / min, and the holding time is 2 hours. After high-temperature pretreatment, the airgel thermal insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com