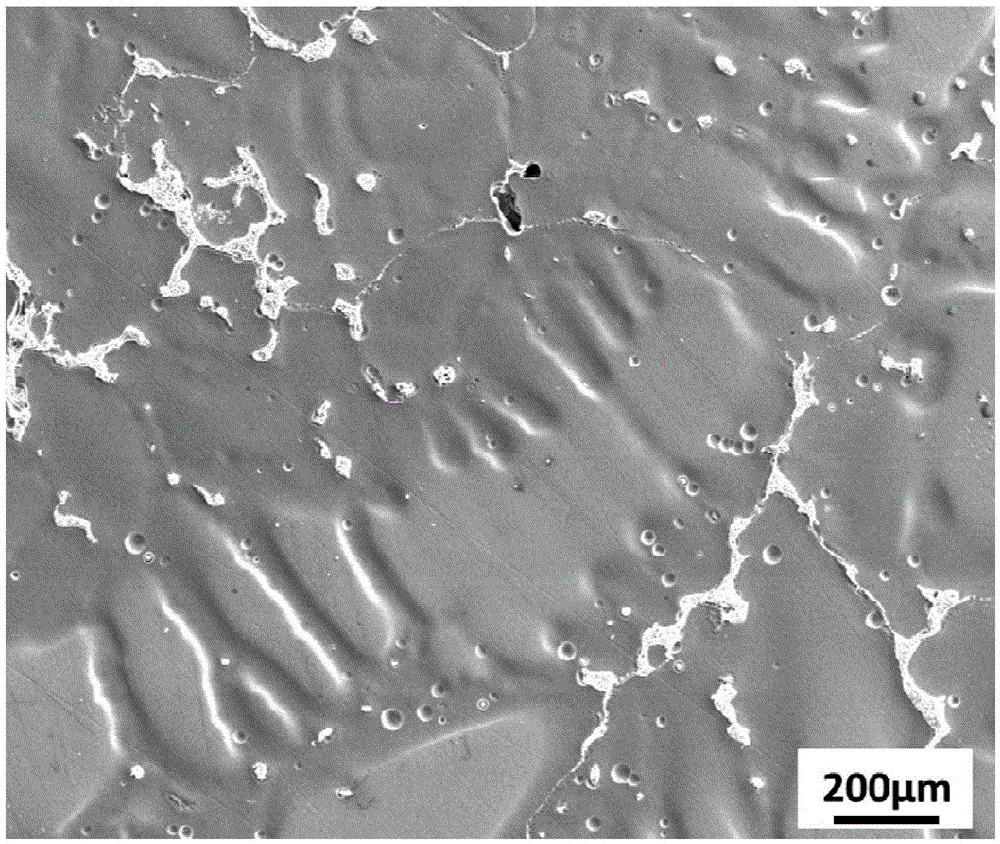

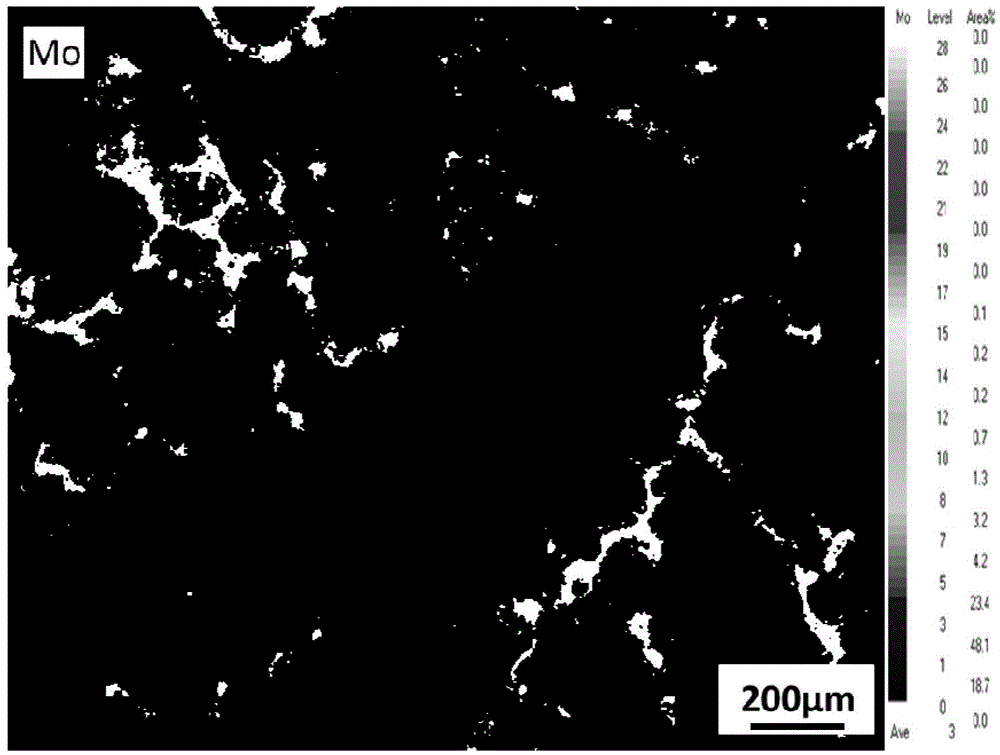

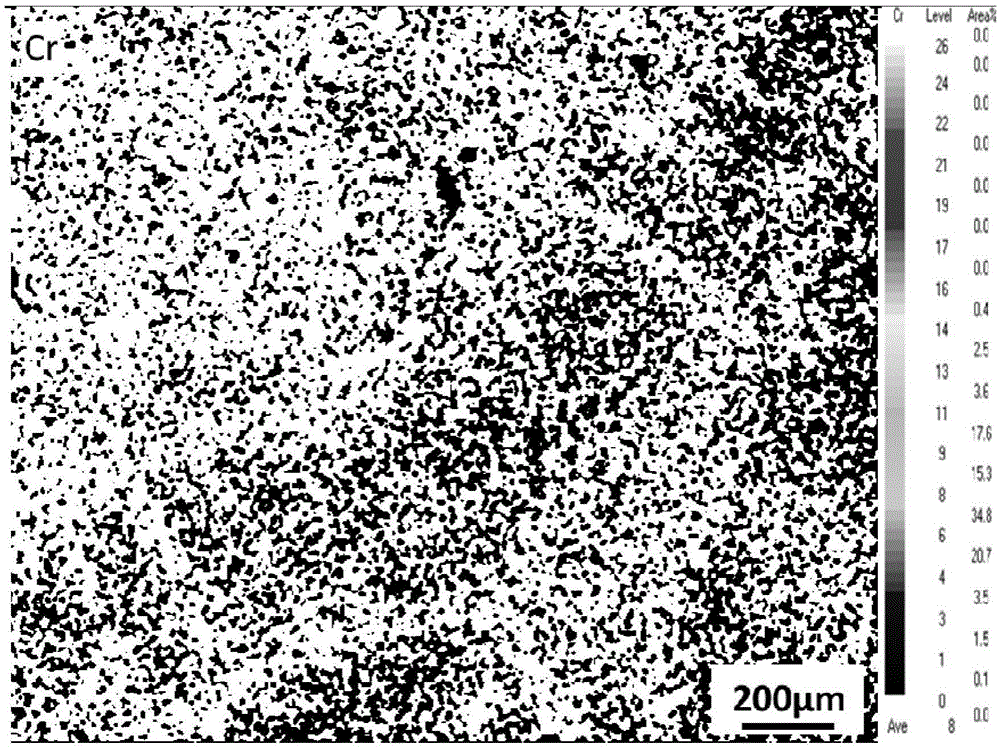

Cast-rolling method for restraining Cr element and Mo element of super-austenitic stainless steel from center segregation

A technology of austenitic stainless steel and super austenite, which is applied in the field of super austenitic stainless steel preparation, can solve problems such as unfavorable economic and environmental sustainable green development, increased material burning loss and energy consumption, and increased environmental tolerance. To achieve the effect of promoting sustainable green development, saving energy and reducing production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A casting-rolling method for suppressing central segregation of chromium and molybdenum elements in super austenitic stainless steel, comprising the following steps:

[0034] Step 1: Weigh the raw materials according to the composition ratio of super austenitic stainless steel, and keep each raw material at 200°C for 120 minutes. Among them, the composition mass percentage of super austenitic stainless steel strip is: C≤0.03%, N: 0.2 %, Si: 0.5%, Cu: 0.35%, Mn: 1.0%, Mo: 6.0%, Cr: 20%, Ni: 24%, P≤0.04%, S≤0.03%, the balance is Fe and unavoidable impurities;

[0035] Step 2: Classify each raw material, put it into a vacuum induction melting furnace step by step, and the vacuum degree is 5Pa, and smelt to obtain molten steel;

[0036] Step 3: Under the protection of high-purity nitrogen, pour molten steel into a twin-roll strip casting and rolling machine for casting and rolling. The pouring temperature is 1520°C, the casting and rolling speed is 27m / min, and the casting...

Embodiment 2

[0040] A casting-rolling method for suppressing central segregation of chromium and molybdenum elements in super austenitic stainless steel, comprising the following steps:

[0041] Step 1: Weigh the raw materials according to the composition ratio of super austenitic stainless steel, and keep each raw material at 200°C for 120 minutes. Among them, the composition mass percentage of super austenitic stainless steel is: C≤0.03, N: 0.2, Si: 0.5, Cu: 0.35, Mn: 1.0, Mo: 6.0, Cr: 20, Ni: 24, P≤0.04%, S≤0.03%, the balance is Fe and unavoidable impurities;

[0042] Step 2: Classify each raw material, put it into a vacuum induction melting furnace step by step, and the vacuum degree is 5Pa, and smelt to obtain molten steel;

[0043] Step 3: Under the protection of high-purity nitrogen, pour molten steel into a twin-roll strip casting and rolling machine for casting and rolling. The pouring temperature is 1520°C, the casting and rolling speed is 27m / min, and the casting and rolling for...

Embodiment 3

[0047] A casting-rolling method for suppressing central segregation of chromium and molybdenum elements in super austenitic stainless steel, comprising the following steps:

[0048] Step 1: According to the composition ratio of super austenitic stainless steel, weigh the raw materials, and keep each raw material at 200°C for 120 minutes. The composition mass percentage of super austenitic stainless steel is: C≤0.03, N: 0.2, Si: 0.5, Cu: 0.35, Mn: 1.0, Mo: 6.0, Cr: 20, Ni: 24, P≤0.04%, S≤0.03%, the balance is Fe and unavoidable impurities;

[0049] Step 2: Classify each raw material, put it into a vacuum induction melting furnace step by step, and the vacuum degree is 5Pa, and smelt to obtain molten steel;

[0050] Step 3: Under the protection of high-purity nitrogen, pour molten steel into a twin-roll thin strip casting and rolling machine for casting and rolling. The pouring temperature is 1520°C, the casting and rolling speed is 27m / min, and the casting and rolling force is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com