Farmland chromium pollution remediation method under planting production condition

A technology of production conditions and repair methods, applied in the field of soil pollution prevention and control, can solve the problems of large environmental disturbance, high cost, and low environmental risk of heterogeneous treatment, and achieve the effect of meeting the requirements of the conditions, low cost, and low repair cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

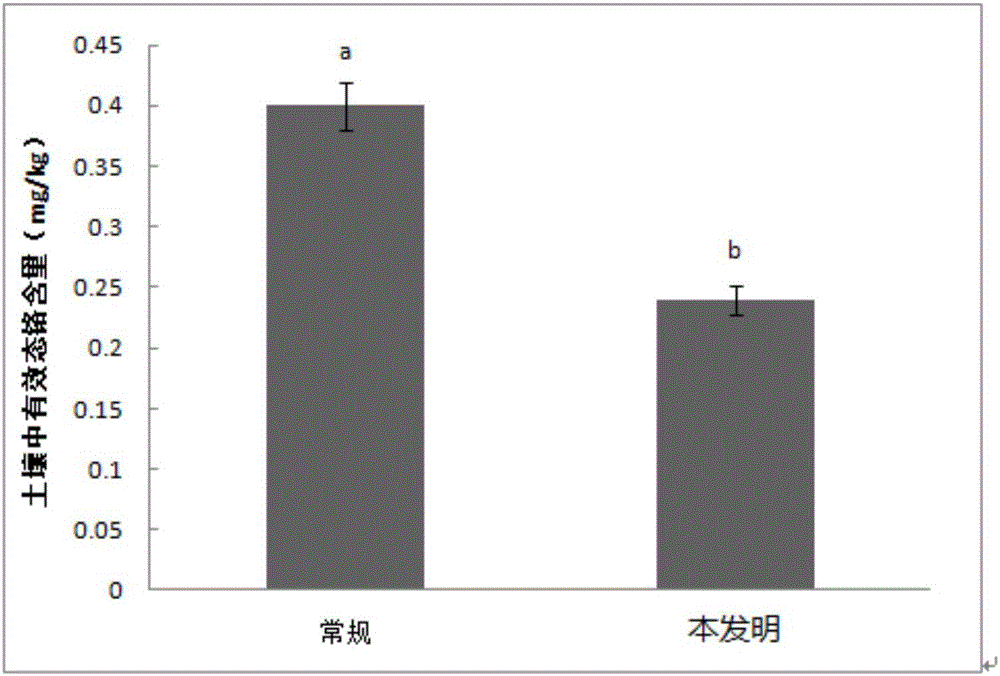

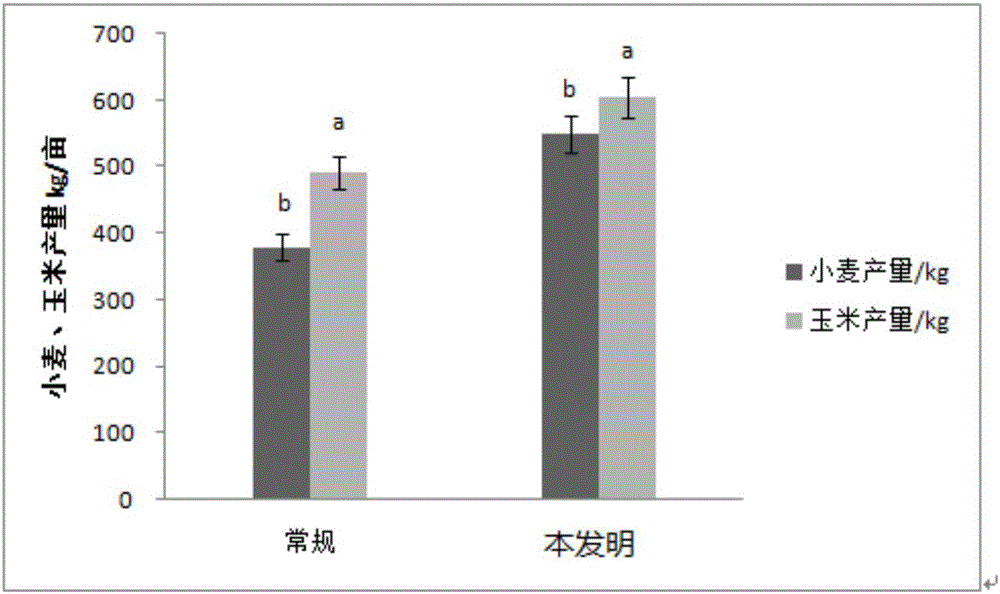

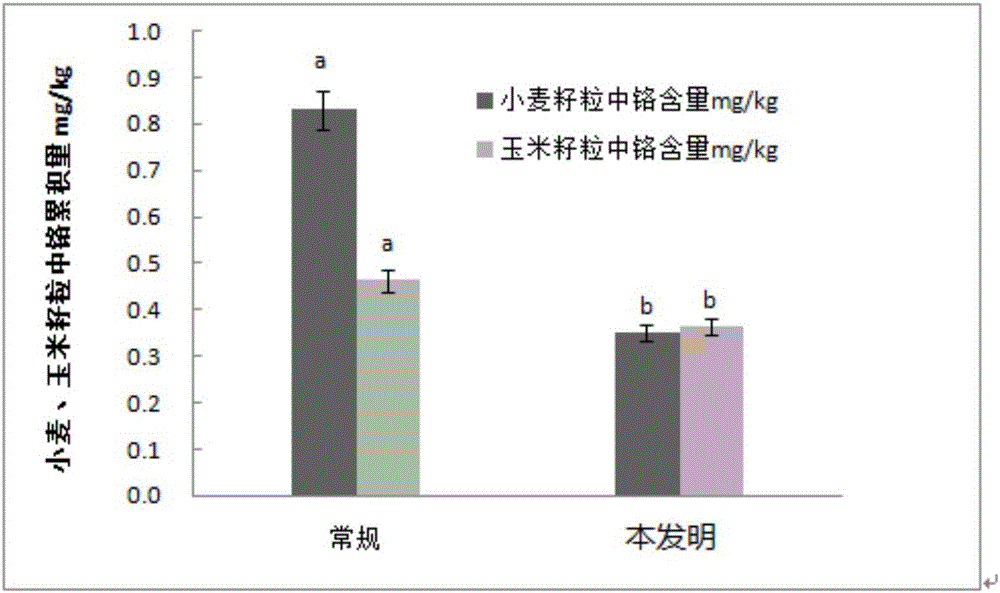

[0053] A method for remediating farmland chromium pollution under planting and production conditions. The heavy metal chromium-contaminated soil in Jinan City, Shandong Province is selected for remediation, and wheat-corn crop rotation is carried out according to the growing season on the soil to be treated. The specific steps are as follows:

[0054] The heavy metal-contaminated soil to be repaired was tested, and the soil contained 127-310 mg / kg of heavy metal chromium; the area was 10 mu, and the land was prepared and leveled in September 2014, and chemical fertilizers were applied (N:P:k:10:10:5 kg / mu). Passivator and organic fertilizer, passivator application rate: 200 kg / mu, organic fertilizer application rate 200 kg / mu, and then deep plowing;

[0055] The raw material components of the heavy metal passivator and their weight percentages are as follows: 75% of ferrous sulfate, 0.8% of mixed bacteria agent, and 24.2% of aluminum oxide.

[0056] In the mixed microbial agen...

Embodiment 2

[0061] A method for repairing chromium pollution in farmland under planting and production conditions. The chromium pollution in Zhaoyuan, Shandong Province was repaired in 2014-2015, and wheat-corn crop rotation was carried out on the soil to be treated according to the growing season. The specific steps are as follows:

[0062] The heavy metal-contaminated soil to be repaired is tested, and the chromium content in the soil is 237-369mg / kg. The area is 50 mu. In the first ten days of March 2014, the land was prepared and leveled, chemical fertilizers were applied (N:P:k:10:10:5 kg / mu), passivating agents and organic fertilizers were applied, and the application rate of passivating agents: 200 kg / Mu, the application rate of organic fertilizer is 200 kg / mu, and then deep plowing;

[0063] The raw material components of the heavy metal deactivator and their weight percentages are as follows: 70% of ferrous sulfate, 0.5% of mixed bacteria agent, and 29.5% of aluminum oxide.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com