Low-alloy high-intensity high-toughness steel and production method of low-alloy high-intensity high-toughness steel

A production method and low-alloy technology, applied in the field of metal materials, can solve problems affecting performance, plastic toughness, wear resistance, etc., and achieve the effect of simple manufacturing and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

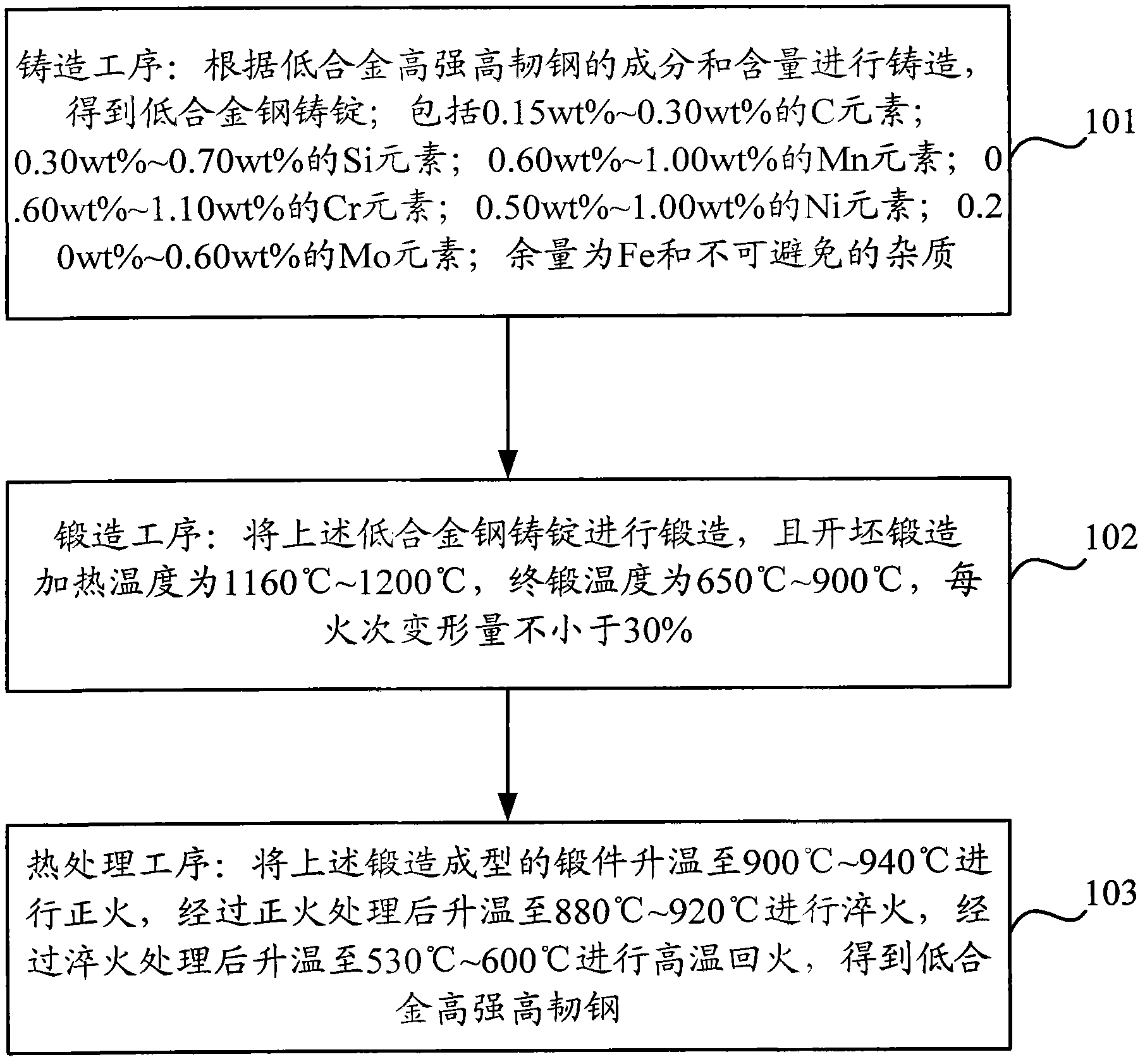

Method used

Image

Examples

Embodiment 1

[0059]Based on the composition and content of the above-mentioned low-alloy high-strength high-toughness steel, Embodiment 1 of the present invention provides a production method of low-alloy high-strength high-toughness steel to realize low-alloy high-strength high-toughness steel with a yield strength of 1000 MPa; and the low-alloy high-strength steel High-toughness steel can solve problems such as alloy chemical element content, material forming process, and increase strength level; this method performs large deformation forging on the as-cast material, and forging can break the as-cast structure, refine the grain, and increase the dislocation density. , improve strength, and at the same time heal some defects formed by casting to prevent the reduction of plasticity and toughness; after forging, quenching + high temperature tempering heat treatment is carried out to obtain tempered sorbite structure, which can obtain high toughness while maintaining high strength.

[0060] ...

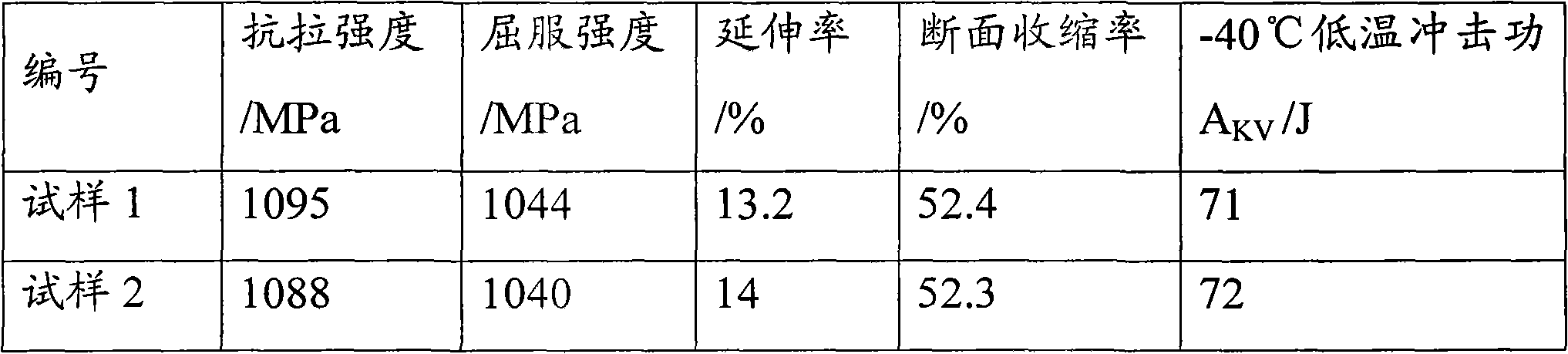

Embodiment 2

[0076] Step 1. Cast a low-alloy high-strength high-toughness steel ingot with the composition shown in Table 1, and the specification of the ingot is Φ100×110mm, and control the process of melting and pouring.

[0077] Table 1 Low alloy steel chemical composition (wt%)

[0078] C

S

P

mn

Si

Cr

Ni

Mo

Al

La

0.25

0.003

0.012

0.72

0.32

1.04

0.83

0.31

0.039

0.0009

[0079] Step 2, forging the ingot obtained in Step 1.

[0080] In the embodiment of the present invention, the heating temperature for blank forging is 1160-1200°C, the final forging temperature is 700°C, the deformation per firing is not less than 30%, and the cross-sectional specification of the forging is 16×80mm.

[0081] Step 3. Heating the forging obtained in step 2 to 930° C., keeping it warm for 3 hours, and cooling to room temperature in the air; this process is a normalizing process.

[...

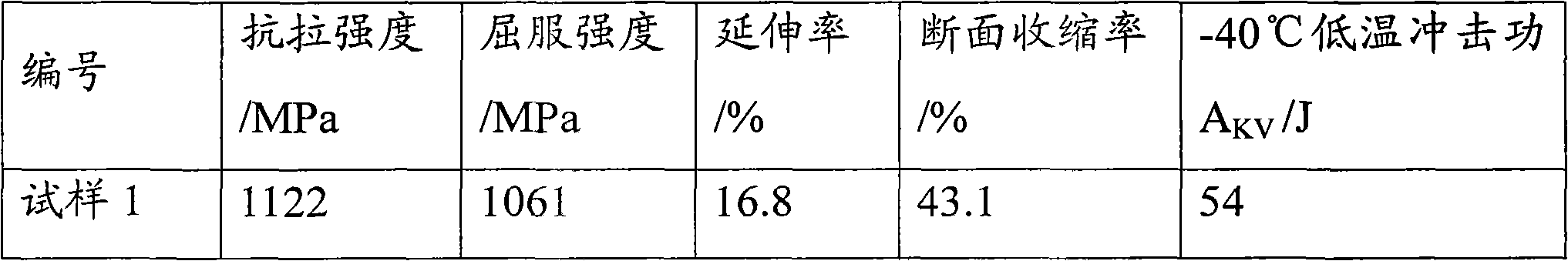

Embodiment 3

[0089] Step 1. Cast a low-alloy high-strength high-toughness steel ingot with the composition shown in Table 3, and the specification of the ingot is Φ100×110mm, and control the melting and pouring process.

[0090] Table 3 Chemical Composition of Low Alloy Steel (wt%)

[0091] C

S

P

mn

Si

Cr

Ni

Mo

Al

La

0.29

0.004

0.017

0.62

0.40

0.85

0.82

0.25

0.046

0.0005

[0092] Step 2, forging the ingot obtained in Step 1.

[0093] In the embodiment of the present invention, the heating temperature for blank forging is 1160-1200°C, the final forging temperature is 750°C, the deformation per firing is not less than 30%, and the cross-sectional specification of the forging is 16×80mm.

[0094] Step 3. Heating the forging obtained in step 2 to 930° C., keeping it warm for 3 hours, and cooling to room temperature in the air; this process is a normalizing process.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com