Patents

Literature

46results about How to "High strength high strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy and preparation method thereof

The invention discloses a low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy and a preparation method thereof. The low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy comprises, by mass, 0.5-3% of Zn, 0.1-0.5% of Ca, 0.1-0.5% of La, 0.1-0.4% of Mn and the balance Mg and unavoidable impurities. The preparation method comprises 1, preparing a magnesium alloy cast ingot, 2, preparing an extruded blank, and 3, carrying out extrusion deformation treatment to obtain the low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy. The low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy has thermal conductivity of 125-140W.(m.k)<-1>, tensile strength of 330-360MPa, yield strength of 310-330MPa and an elongation percentage of 15-35%.

Owner:BAOSHAN IRON & STEEL CO LTD

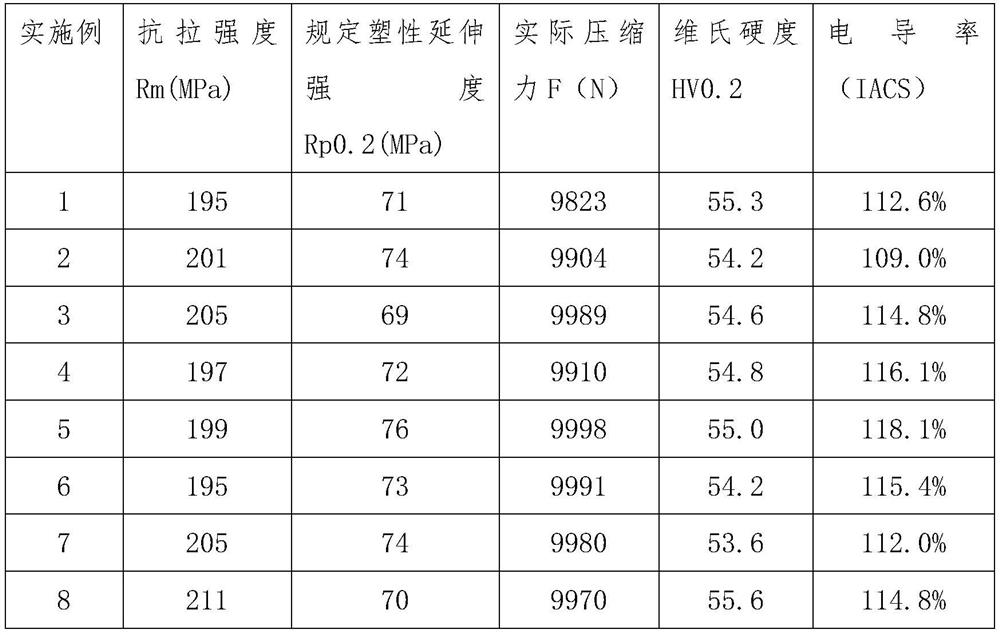

Manufacturing method of 6063T6 aluminum alloy large-scale bar for power equipment

The invention belongs to the technical field of aluminum alloy materials for power equipment, and particularly relates to a manufacturing method of a high-strength high-conductivity aluminum alloy large-scale bar. A 6063 high-strength high-conductivity large-specification bar is used for processing a high-strength high-conductivity large electric element in power equipment, particularly a 6063T6 aluminum alloy bar with a diameter over 150-300mm. A sixth-system round aluminum alloy ingot is adopted and contains the following elements in percentage by mass: 0.40-0.44% of Si, less than or equal to 0.13% of Fe, less than or equal to 0.1% of Cu, less than or equal to 0.10% of Mn, 0.55-0.60% of Mg, less than or equal to 0.05% of Zn, less than or equal to 0.05% of Ti, less than or equal to 0.10% of Cr, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of all impurities and the balance of Al. The problems in production and delivery can be effectively solved, the strength and conductivity of the large-specification aluminum alloy bar are improved, and the processing and application are facilitated; by adopting the method, the mechanical properties and conductivity are stable; and through repeated reproduction operations, the national standard for a diameter below 150mm can be met, the national standard for bars with diameters over 150-300mm can be supplemented or completed, and all performance indexes are introduced into the national standard.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

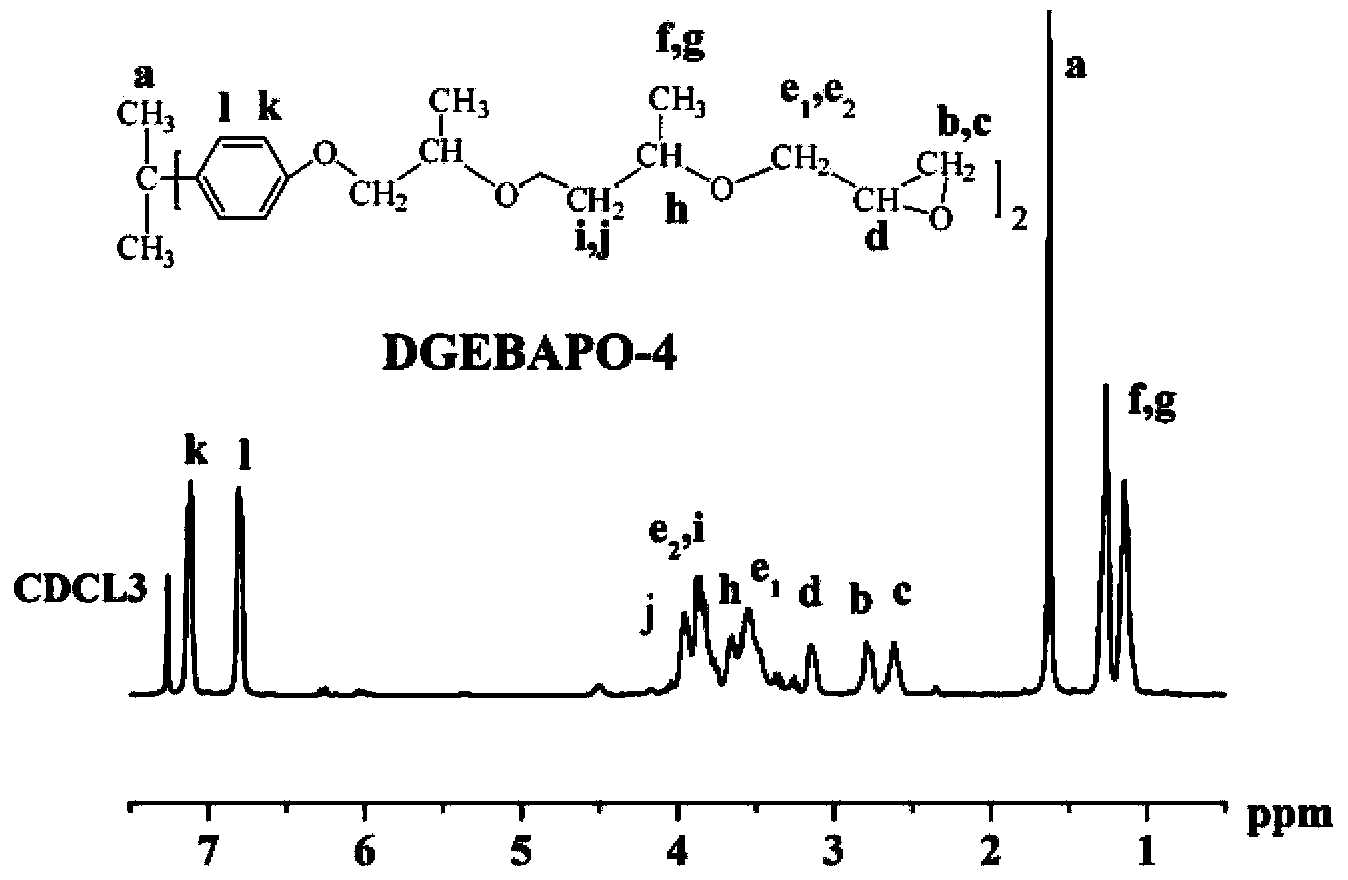

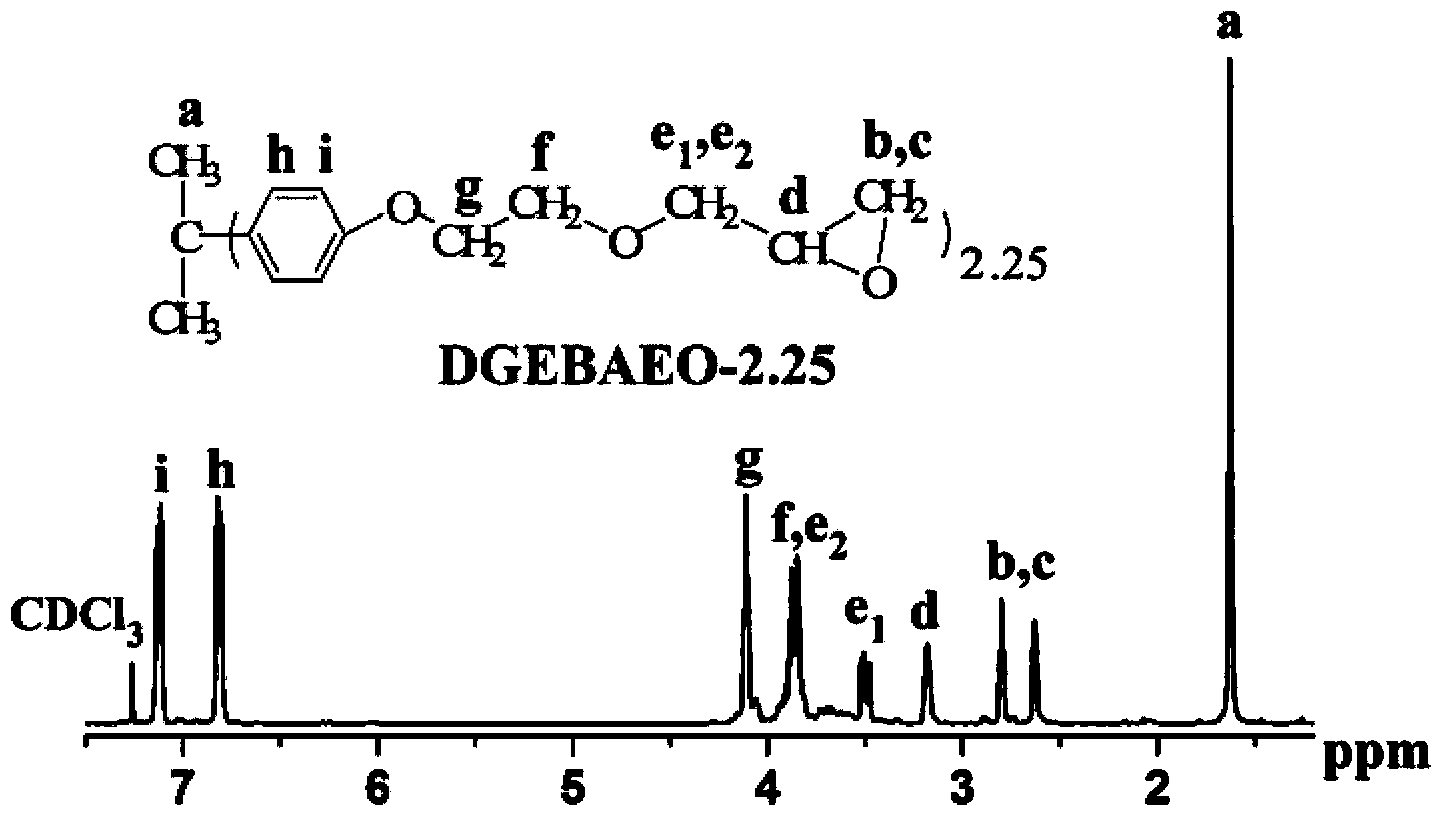

High strength and high toughness epoxy resin composition applicable for hot melt method preparation of carbon fiber reinforced composite prepreg

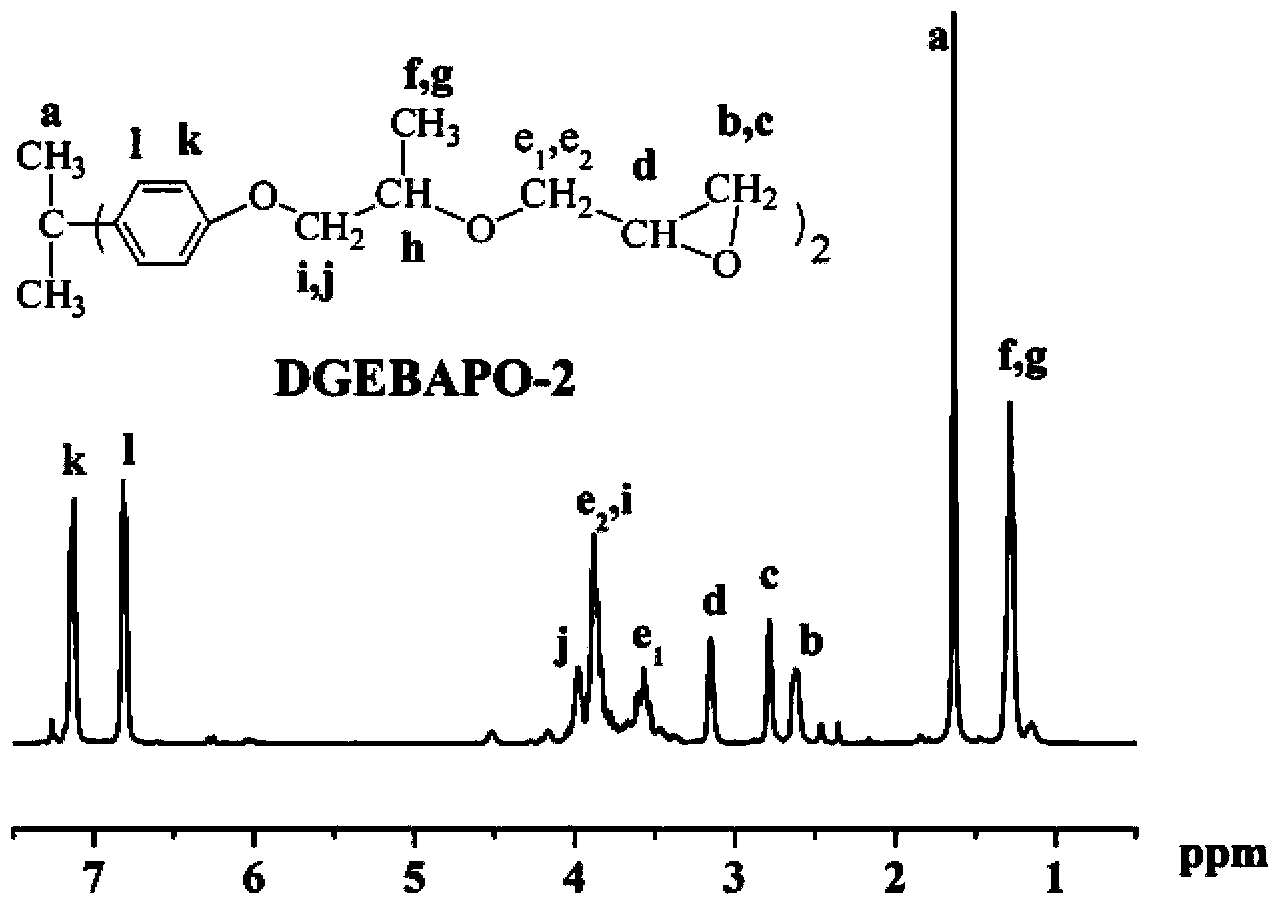

The invention relates to a high strength and high toughness epoxy resin composition applicable for hot melt method preparation of a carbon fiber reinforced composite prepreg. The high strength and high toughness epoxy resin composition comprises epoxy resin with multiple degrees of functionality and high epoxy value, bisphenol A polyether epoxy resin with low viscosity, high performance thermoplastic resin and a solid curing agent. The high strength and high toughness epoxy resin composition provided by the invention has the advanategs of flexible formula, simple preparation process and adjustable viscosity, is especially suitable for hot melt preparation of prepreg; and the cured material has the characteristics of high strength and high toughness, and can used for preparation of composite materials with high mechanical properties.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-strength copper alloy for thin-belt continuous casting crystallization roller and method for manufacturing same

The invention discloses a high-strength and high-conductive copper alloy of continuous casting thin-belt crystal roll, which comprises the following parts: 1-2.5% Ni, 0.05-0.2% Si,0.05-0.2% Zr, 0.2-0.4% Cr, 0.05-0.1% Sn, one or more of Fe, Co and Mg with total quantity less than 0.15% and Cu, wherein the rate of Ni and Si is more than 8: 1. The making method comprises the following steps: adding Ni, Zr, Co and Sn to exert alloy element action; heating; obtaining the copper alloy material without beryllium.

Owner:BAOSHAN IRON & STEEL CO LTD

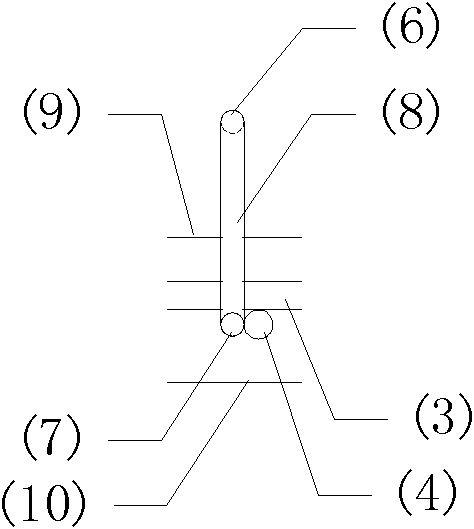

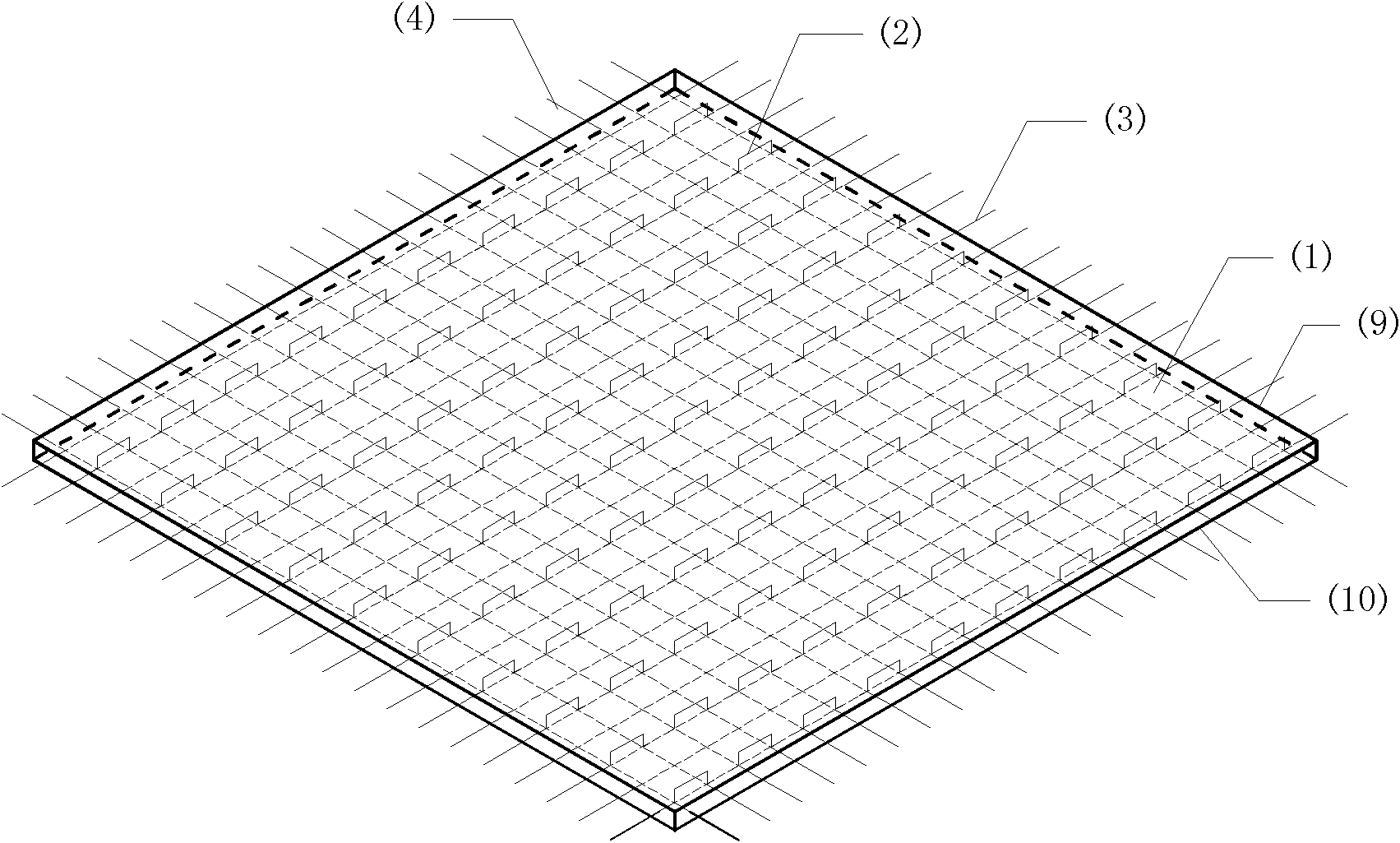

Ultrahigh-strength and ultrathin bottom board for laminated slab and production method thereof

InactiveCN102121289AHigh strengthImprove crack resistanceFloorsCeramic shaping apparatusSocial benefitsCrack resistance

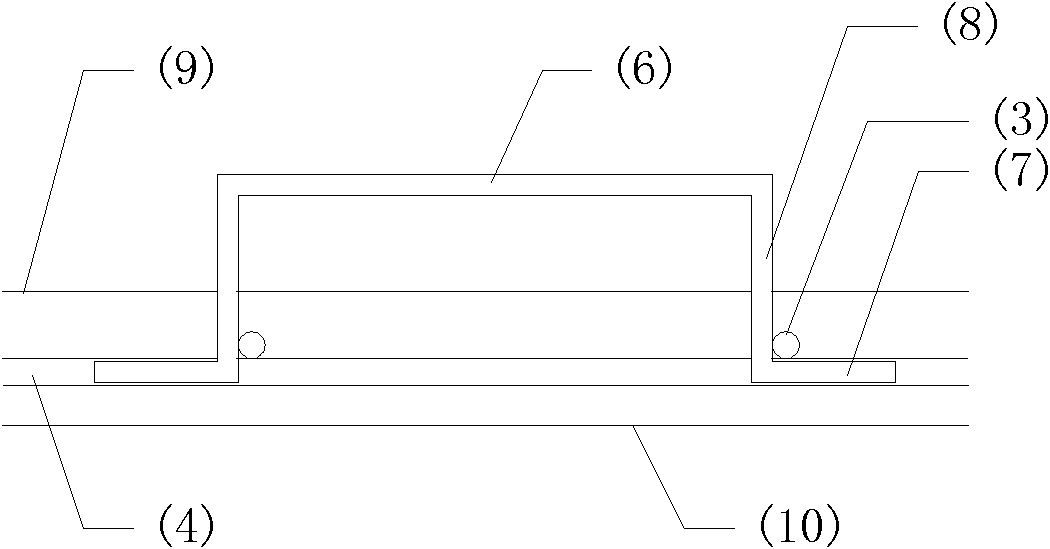

The invention provides an ultrahigh-strength and ultrathin bottom board for a laminated slab and a production method thereof. The ultrahigh-strength and ultrathin bottom board comprises a bottom board made of a fiber-toughened cement-based composite material, wherein a longitudinally and horizontally-distributed steel wire mesh formed by longitudinally-distributed bars and horizontally-distributed steel bars is arranged in the bottom board, and an interface shear-resistant connecting piece is arranged on the steel wire mesh. The ultrahigh-strength and high-performance fiber-toughened cement-based composite material is applied to the design of a bottom board of the laminated slab, so that ultrahigh-strength and ultrathin bottom board for the laminated slab is formed. The bottom board has the advantages of ultrahigh strength, thin thickness, high crack resistance, light weight, durability and the like, and can create great economic and social benefits after being popularized.

Owner:HARBIN ENG UNIV

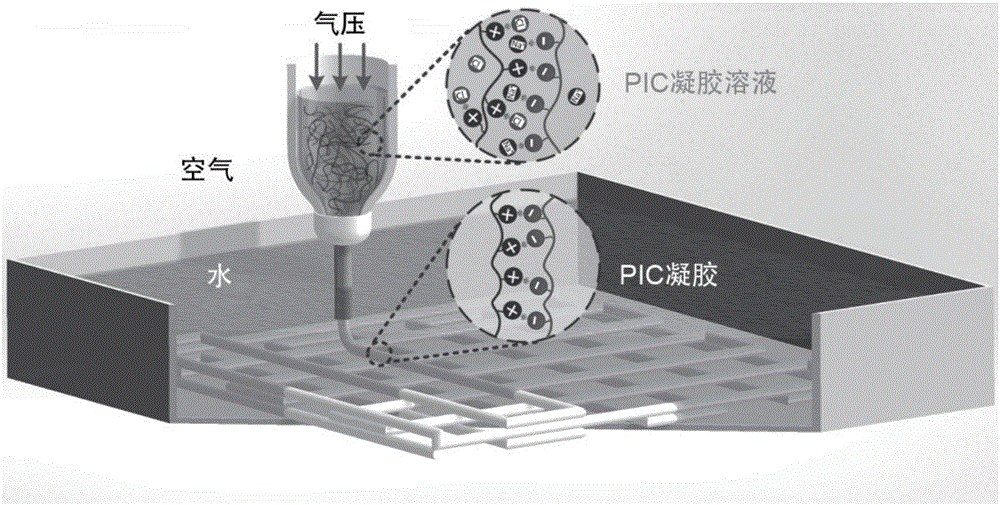

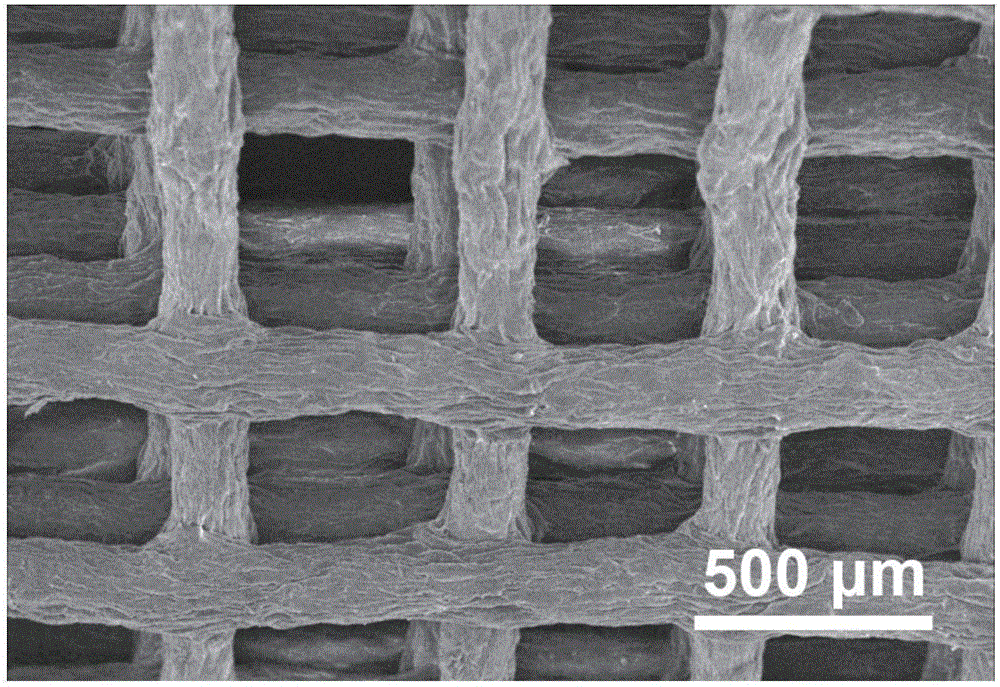

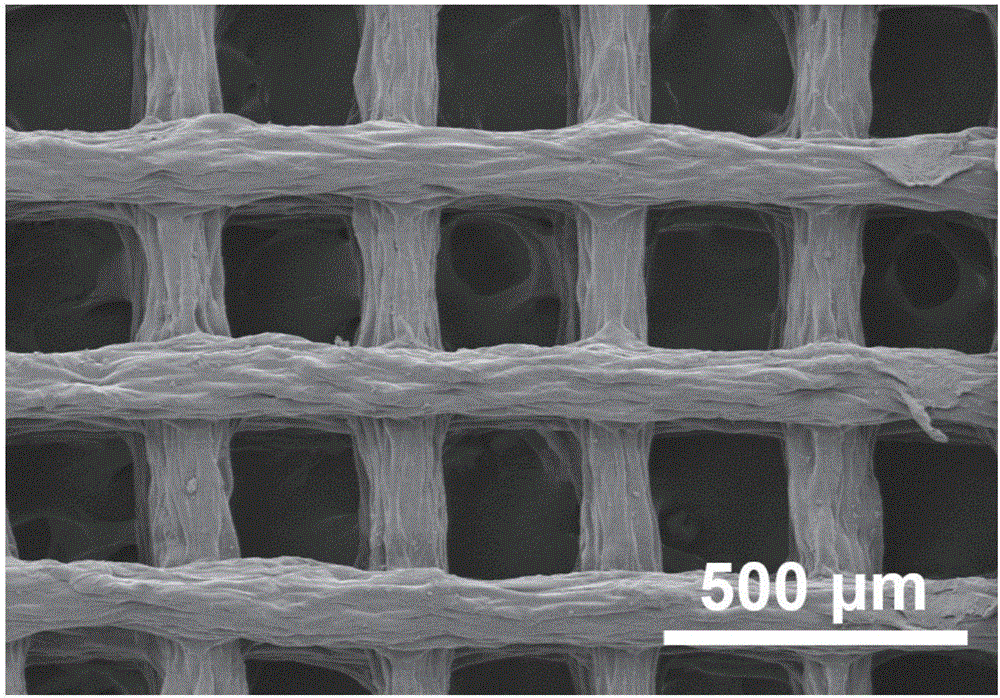

Method for preparing high-strength and high-toughness poly-ion hydrogel support through 3D printing

ActiveCN106267366AHigh strengthImprove toughnessAdditive manufacturing apparatusProsthesisCross-linkPolymer science

The invention discloses a method for preparing a high-strength and high-toughness poly-ion hydrogel support through 3D printing. The method includes the steps that an N,N,N-trimethyl-3-(2-methyl allyl acylamino)-1-propyl ammonia chloride solution to which a photoinitiator is added and a sodium p-styrenesulfonate solution are put below an ultraviolet lamp to be irradiated, solutions of two polymers are obtained, and two kinds of polymer powder are obtained after purifying, drying and grinding are completed; the two kinds of polymer powder are prepared into a water solution, the water solution is mixed and stirred, polyion compound precipitates are obtained, collected and dried, and polyion compound powder is obtained; saline is added into the polyion compound powder, the materials are stirred to be uniform, and polyion gel is obtained; a 3D printer is used for extruding the polyion gel in pure water under set printing parameters, and the poly-ion gel support is obtained after soaking and cross-linking forming. According to the method, bio-supports with different micro-structures and macro-appearances can be printed by correcting the printing parameters while it is guaranteed that the support has good mechanical performance.

Owner:ZHEJIANG UNIV

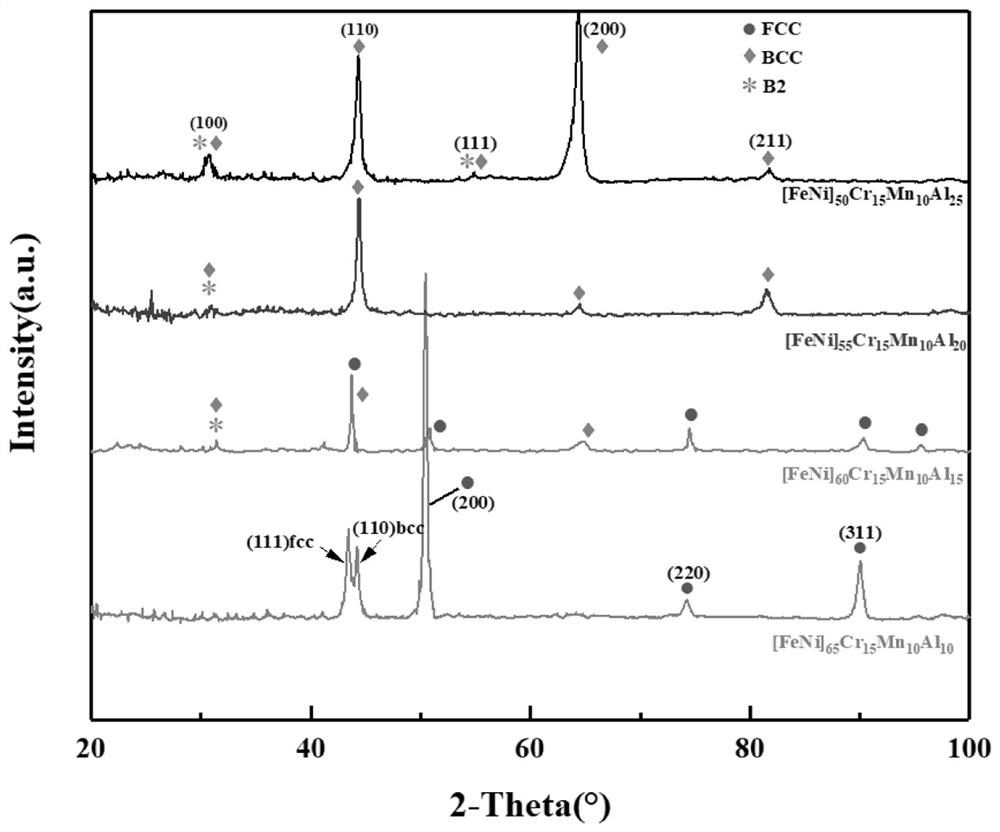

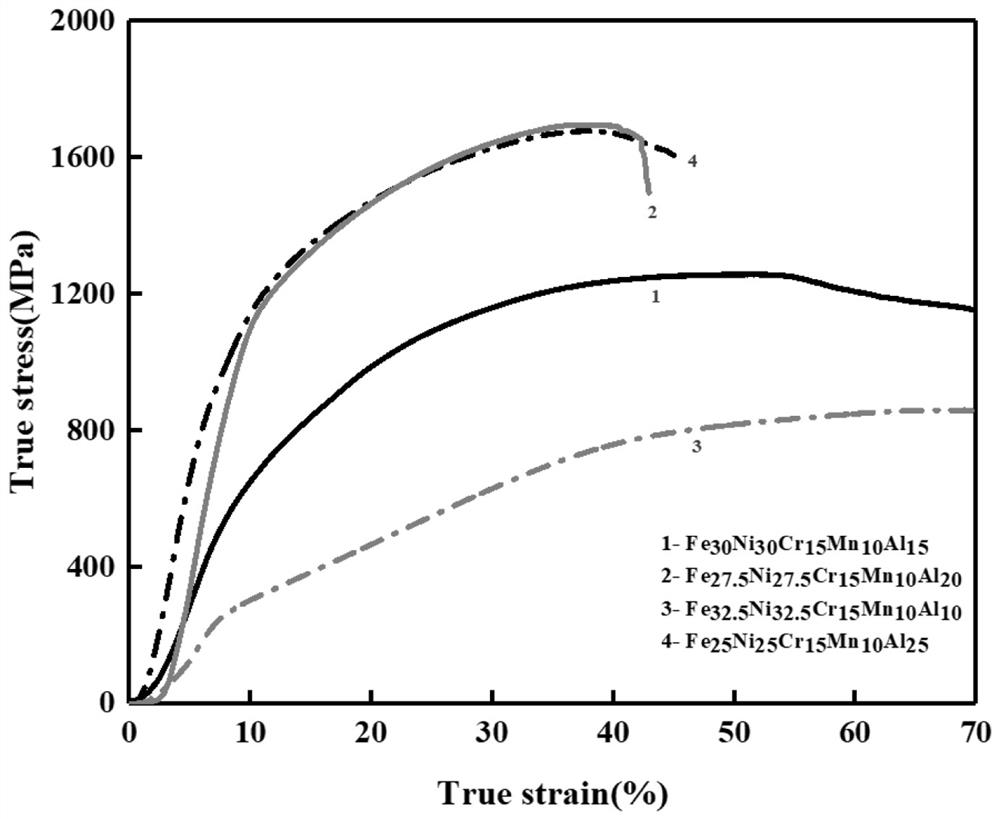

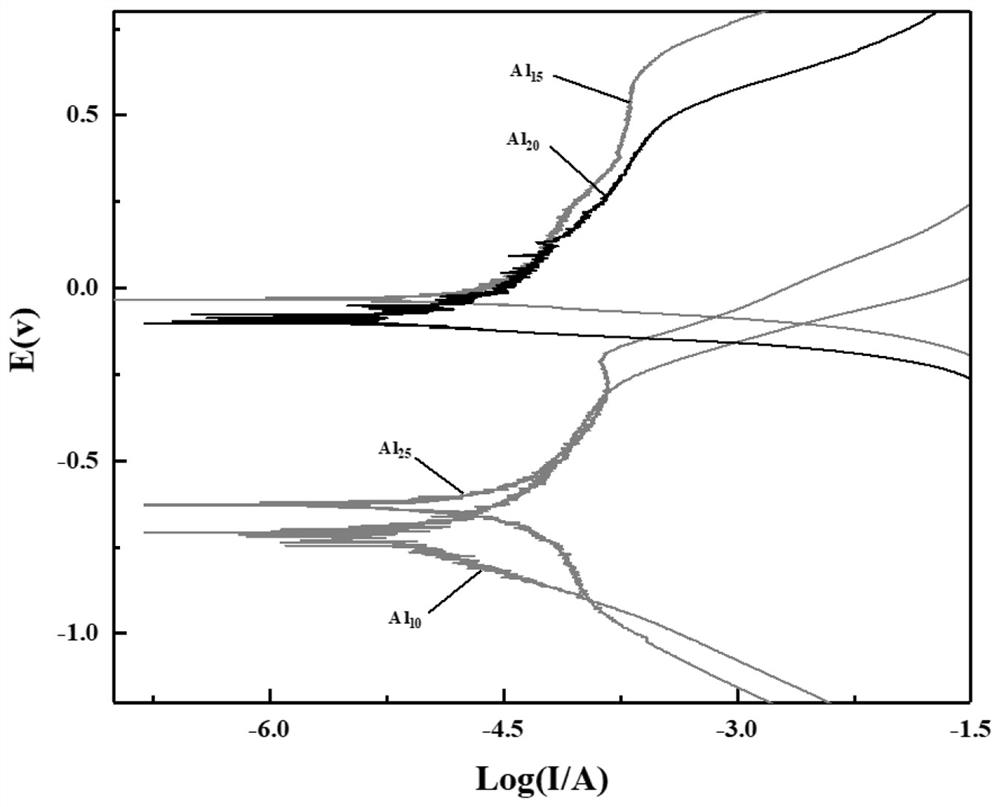

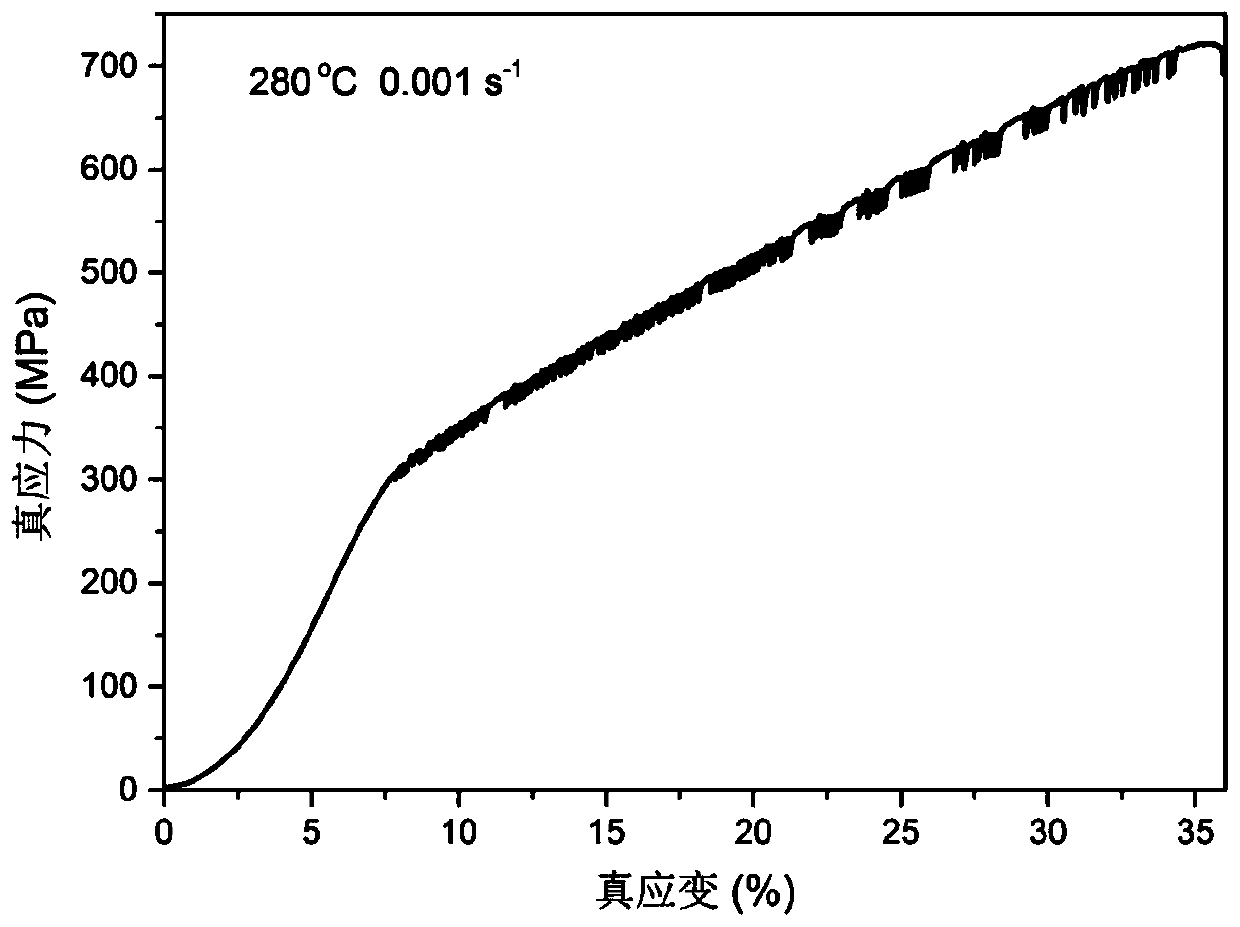

High-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy and preparation method thereof

The invention discloses high-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy and a preparation method thereof. In the high-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy, the atomic percent of Fe: Ni: Cr: Mn: Al is 30-27.5% : 30-27.5% : 15% : 10% : 15-20%. A preparation technology of the high-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy comprises the following steps: selecting the five elements including Fe, Ni, Cr, Mn and Al with the purity of each being 99.9wt% as the raw material for batching, and utilizinga non self-consuming electric arc furnace to prepare the high-entropy alloy through smelting. The high-entropy alloy is uniform in texture, shows excellent comprehensive mechanical property, does notcontain the expensive Co element and is low in price. The yield strength of the high-entropy alloy is equal to or greater than 770MPa, the breaking strain is equal to or greater than 45%, the corrosion resistance of the high-entropy alloy to 3.5wt.% NaCl is better than the corrosion resistance of stainless steel SUS 304 to 3.5wt.% NaCl, and the application prospect is broad.

Owner:CHINA THREE GORGES UNIV

Ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy and preparation method thereof

The invention provides an ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy which contains nickel, tine, yttrium, niobium, scandium and cerium elements. The total mass of theyttrium, niobium, scandium and cerium elements is less than or equal to 0.5 percent of the mass of the copper-nickel-tin alloy. The copper-nickel-tin alloy has high strength, toughness and conductivity, and is wide in application range. The invention further provides a preparation method of the copper-nickel-tin alloy. The preparation method of the copper-nickel-tin alloy concretely comprises thesteps of preparing materials according to the mass percent of element compositions, and adopting a gas atomization method for preparing to obtain alloy powder; adopting hot isostatic pressure sintering on the alloy powder to obtain a copper-nickel-tin alloy ingot blank; and carrying out solution treatment and warm deformation strengthening treatment on the copper-nickel-tin alloy ingot blank so as to obtain the ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy. According to the preparation method, multiple compound factor strengthening and toughening copper alloys are implemented and utilized, and the obtained copper-nickel-tin alloy has the characteristics of refined crystalline strengthening, strain strengthening, dispersion strengthening and precipitation hardening at the same time so as to obtain high strength, toughness and conductivity.

Owner:CENT SOUTH UNIV

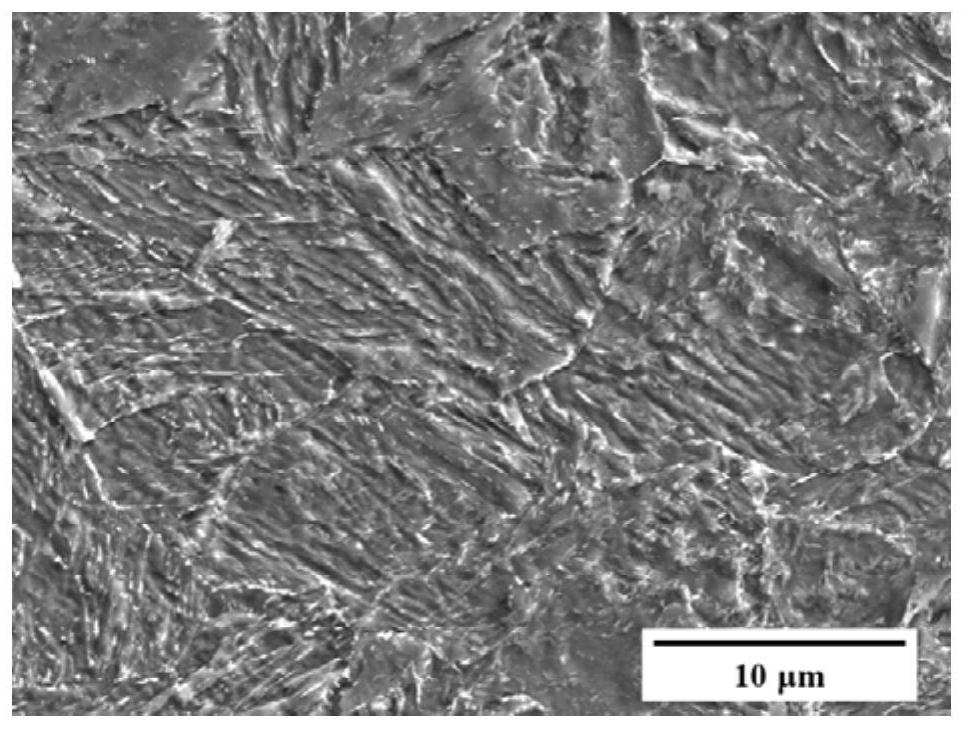

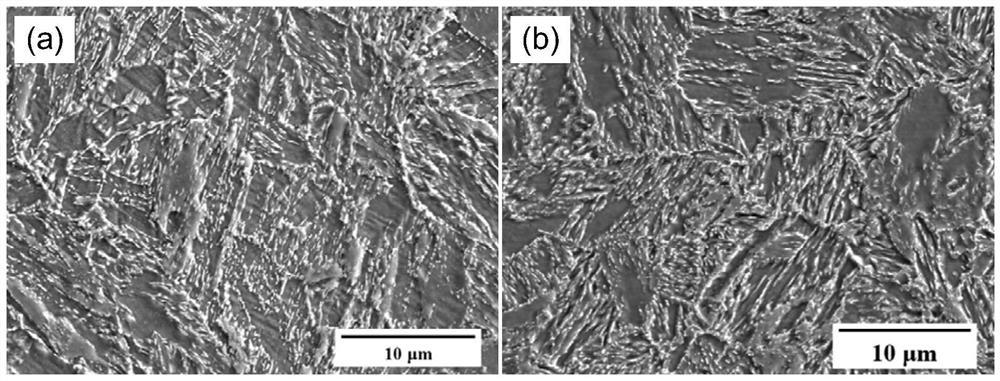

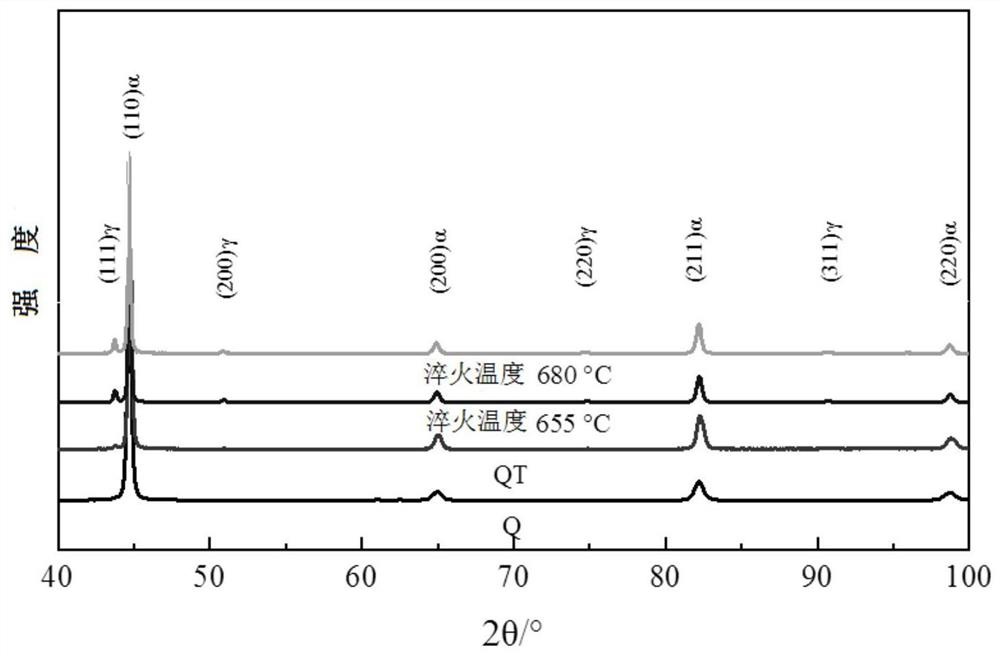

Low-yield-ratio, ultra-high-strength and high-tenacity steel for pressure-resisting shell, and preparation method of low-yield-ratio, ultra-high-strength and high-tenacity steel

ActiveCN111705268AHigh strengthImprove plasticityFurnace typesHeat treatment furnacesTemperingUltimate tensile strength

The invention discloses low-yield-ratio, ultra-high-strength and high-tenacity steel for a pressure-resisting shell, and a preparation method of the low-yield-ratio, ultra-high-strength and high-tenacity steel. The low-yield-ratio, ultra-high-strength and high-tenacity steel is prepared from the chemical components in percentage by weight: 0.05-0.10% of C, 0.15-0.35% of Si, 0.60-1.00% of Mn, 0.10-0.50% of Cu, 0.10-1.00% of Mo, 0.40-0.70% of Cr, 0.05-0.15% of V, 5.00-10.00% of Ni, and the balance of Fe and inevitable impurities. According to the technical scheme, two times of quenching heat treatment is adopted, first-time quenching is conducted to enable the steel to be completely austenitized, then second-time quenching and tempering are conducted, finally heterogeneous structures such astempered martensite, critical ferrite and residual austenite are obtained, and thus performance index requirements of a low yield ratio, ultra high strength and high tenacity are met, so that application of the low-yield-ratio, ultra-high-strength and high-tenacity steel in practice is promoted.

Owner:NORTHEASTERN UNIV LIAONING

High-strength and high-toughness wear-resistant composite steel plate and manufacturing method thereof

ActiveCN109835014AImprove performanceImprove refinementFurnace typesMetal rolling arrangementsWear resistantHardness

The invention discloses a high-strength and high-toughness wear-resistant composite steel plate. The composite steel plate comprises a substrate layer and a composite layer compounded to one side or two sides of the substrate layer; and the substrate layer is a carbon steel layer, the composite layer is an ultrahigh-manganese steel layer, and the content of Mn element in the composite layer is 16.00-25.00 wt.%. The invention also discloses a manufacturing method of the high-strength and high-toughness wear-resistant composite steel plate. The manufacturing method comprises the following steps:(1) producing a substrate layer slab and a composite layer slab; (2) assembling the slabs; (3) heating: raising the temperature to 1150-1250 DEG C, and keeping the temperature for 1-3 h; (4) carryingout composite rolling: rolling at an initial rolling temperature of 1120-1220 DEG C and a finishing rolling temperature of 1050-1200 DEG C, and controlling the reduction ratio to be 50% or above; and5) cooling after rolling. The high-strength and high-toughness wear-resistant composite steel plate of the invention has the advantages of high strength and hardness, good toughness, high wear resistance and excellent comprehensive performances.

Owner:BAOSHAN IRON & STEEL CO LTD

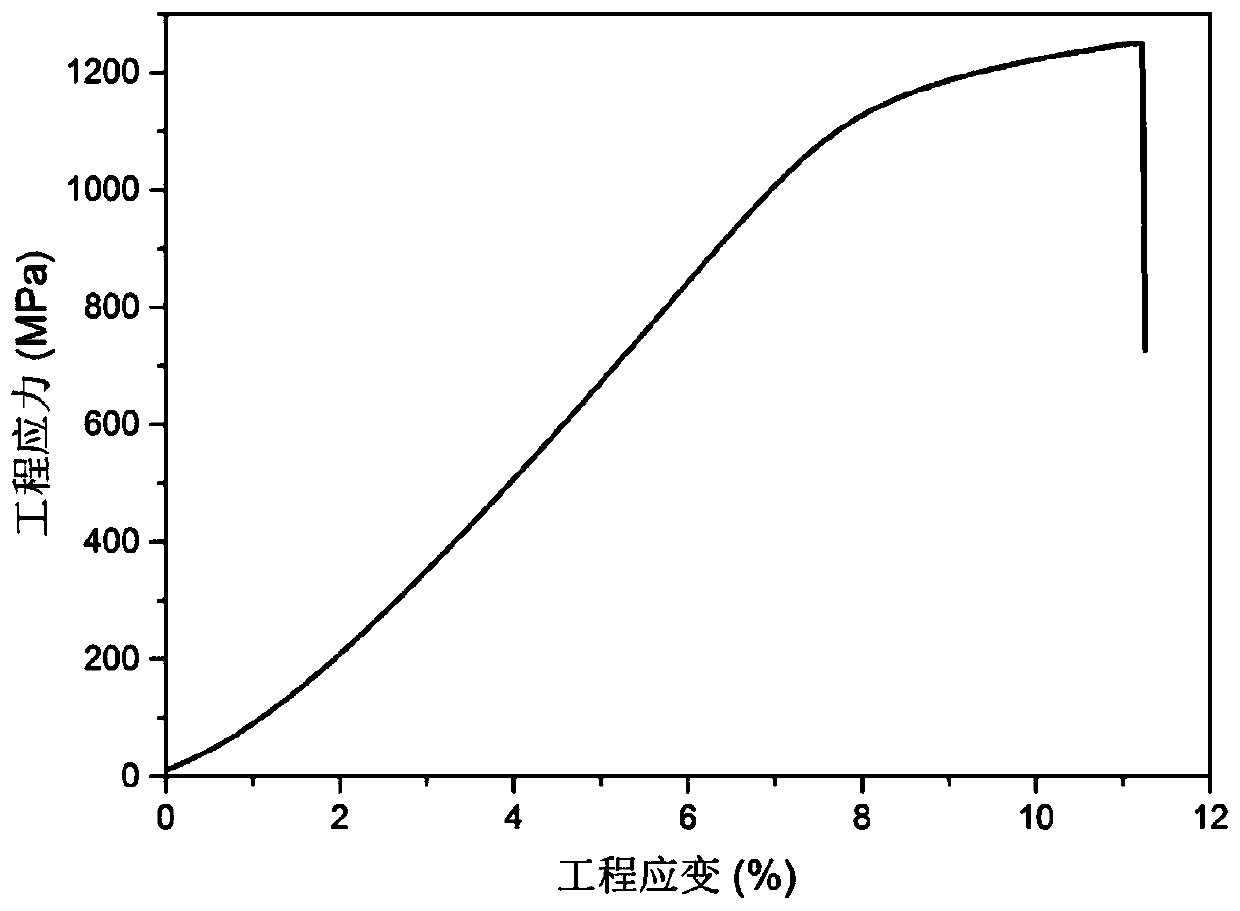

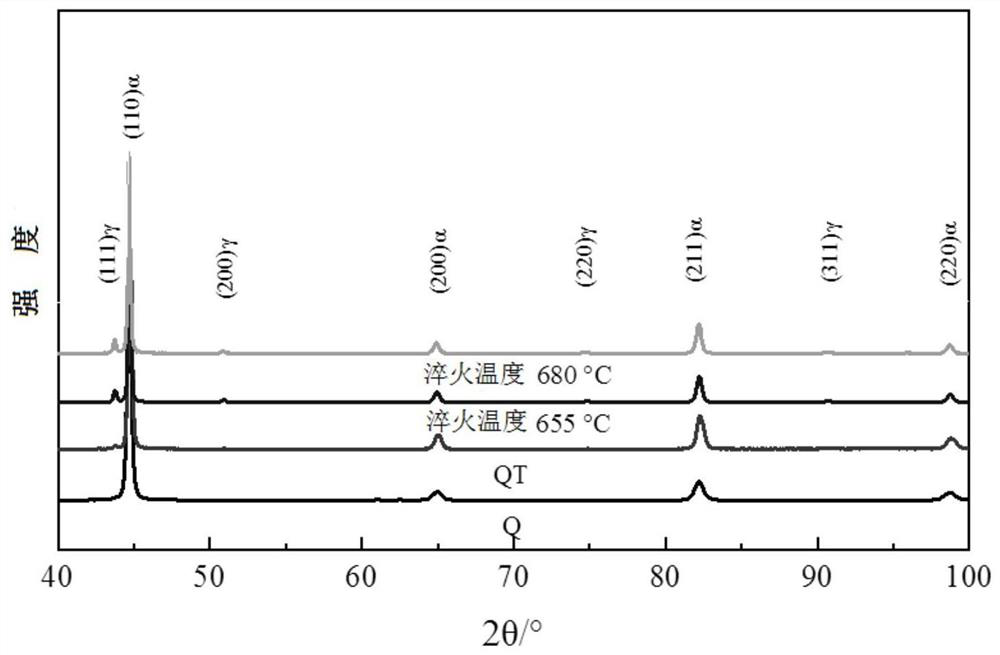

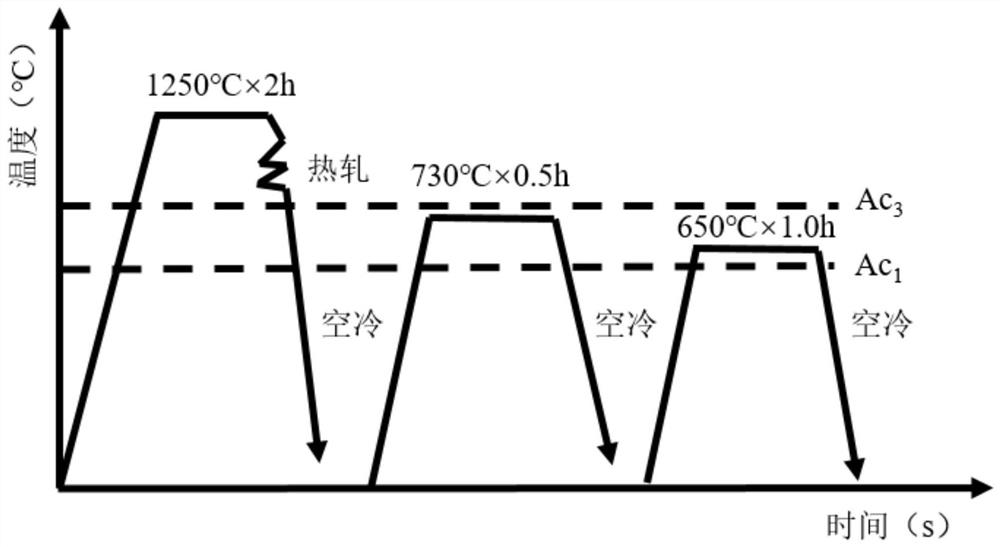

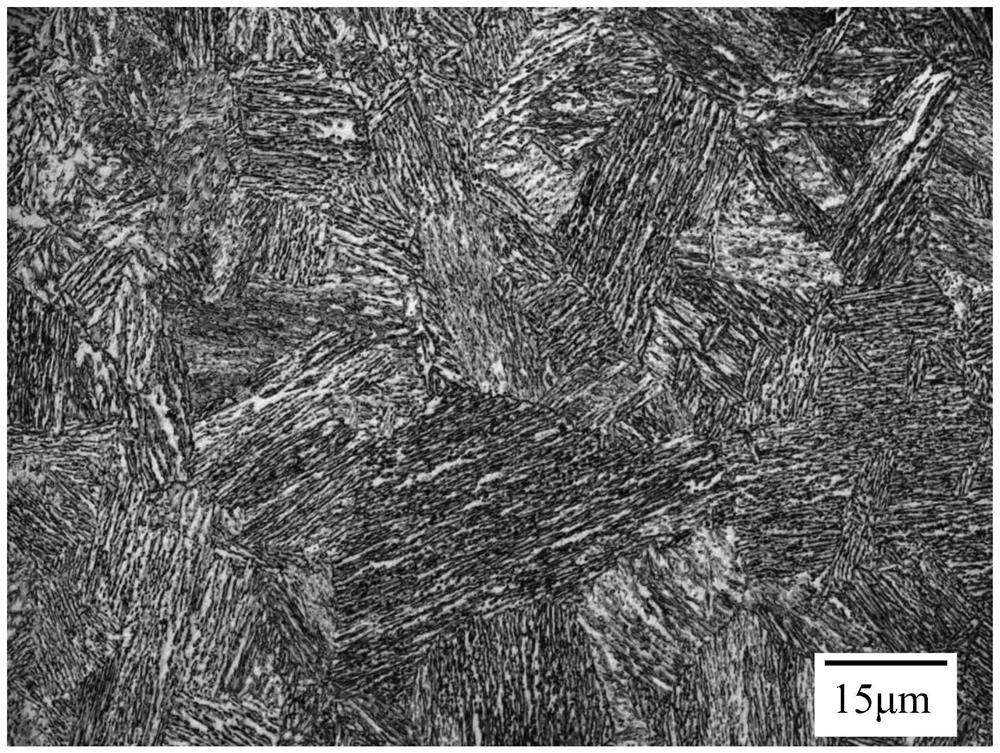

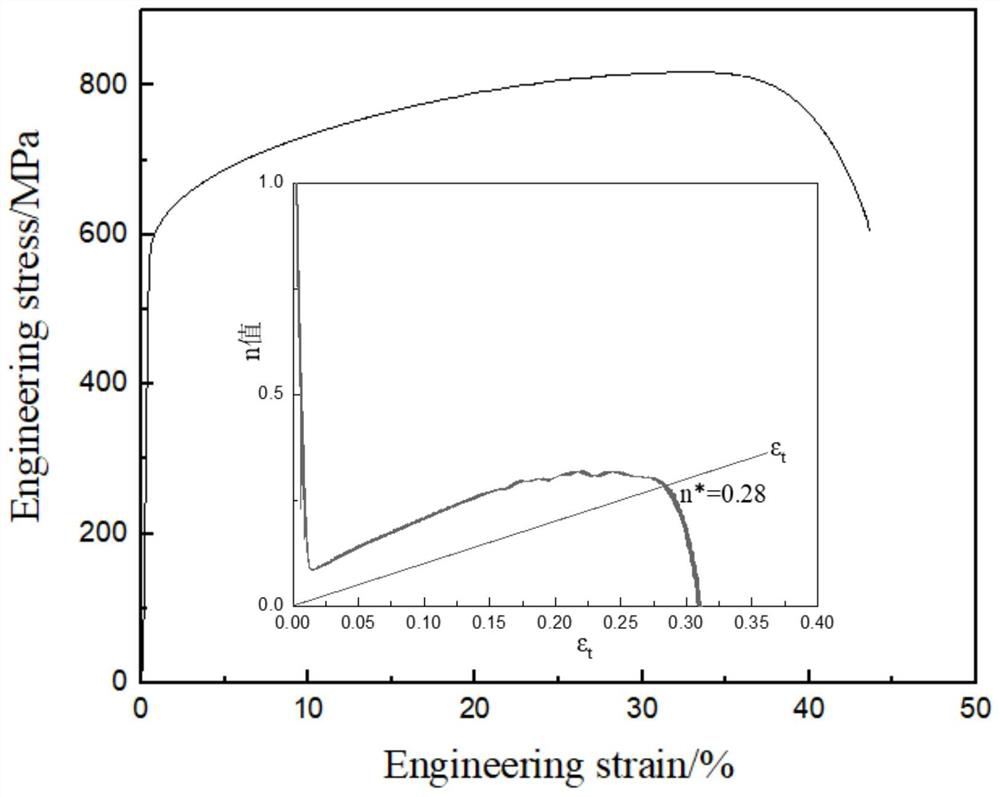

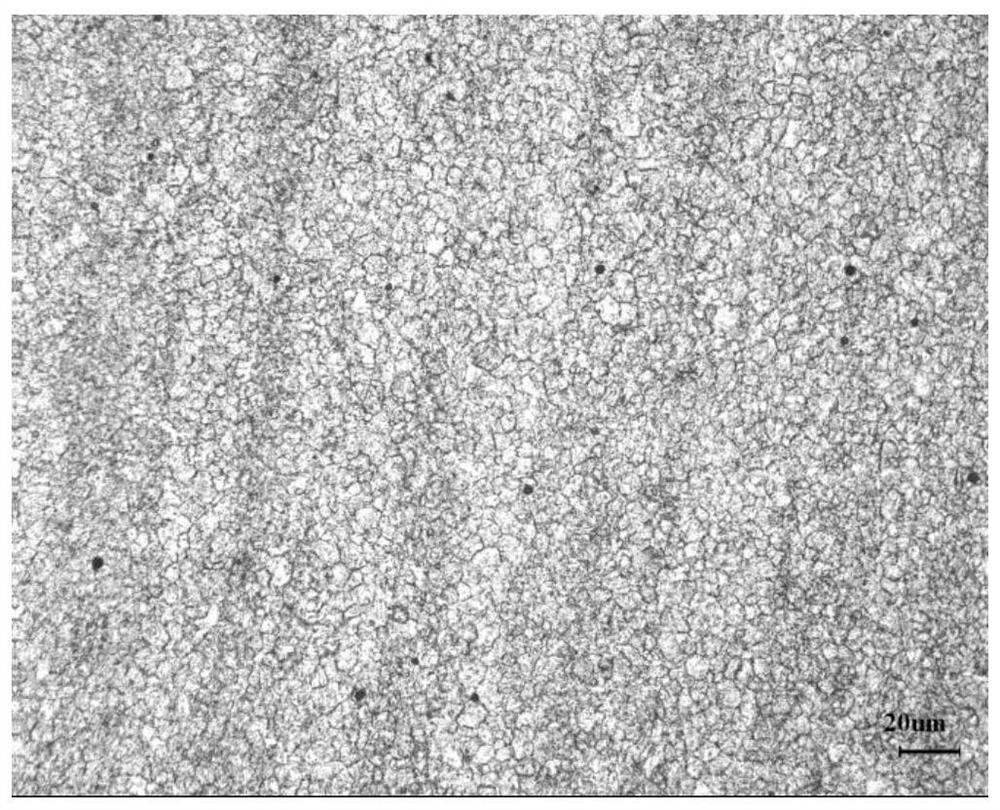

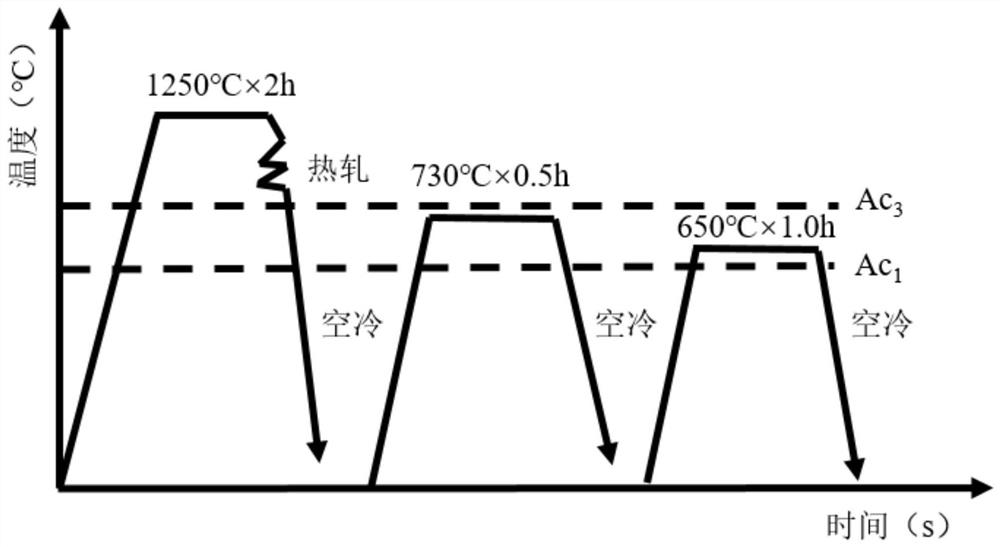

High-strength, high-plasticity, low-carbon and medium-manganese TRIP steel and preparation method thereof

ActiveCN112853224AHigh strengthImprove plasticityFurnace typesHeat treatment process controlPlasticityContinuous production

The invention discloses high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel and a preparation method thereof, and belongs to the technical field of high-strength and high-plasticity steel. The high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel comprises the following components in percentage by mass: 0.08%-0.16% of C, 2.9%-4.0% of Mn, 0.1%-1.5% of Si, 0.01%-0.08% of Al, 0.005%-0.04% of Ti, less than 0.015% of P, less than 0.003% of S, and the balance of Fe and inevitable impurity elements. According to the preparation method, the raw materials with the chemical components are subjected to smelting, casting, forging, hot rolling and two-step annealing treatment in a two-phase region, the high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel is high in strength, high in plasticity and good in impact toughness, the components of the high-strength, high-plasticity, low-carbon and medium-manganese TRIP steel and the heat treatment process are simple and feasible, and industrial continuous production is easy to achieve.

Owner:NORTHEASTERN UNIV

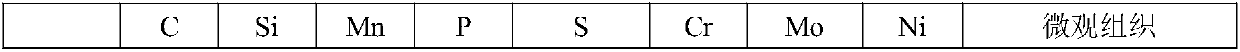

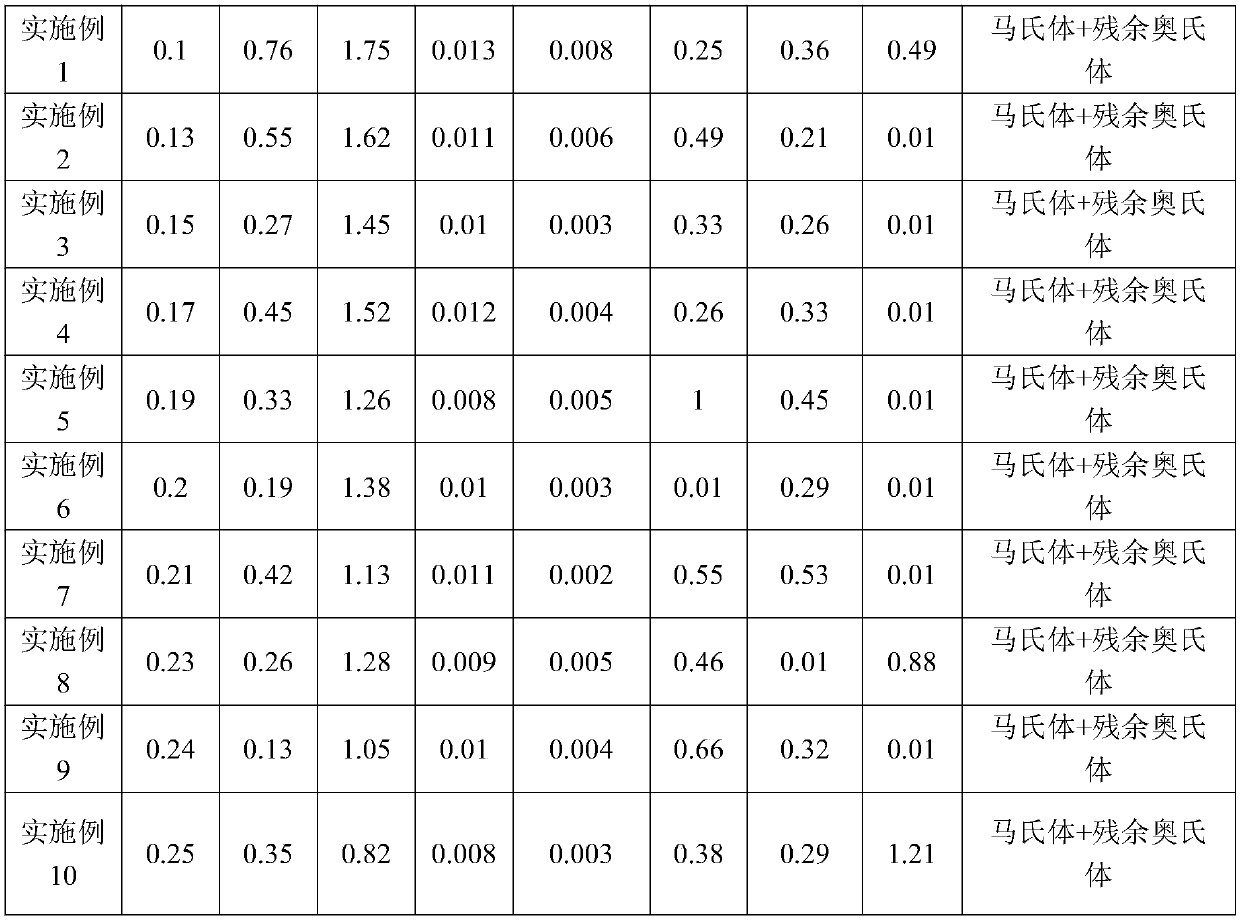

Thick-wall high-strength high-toughness oil casing pipe and manufacturing method thereof

The invention discloses a thick-wall high-strength high-toughness oil casing pipe which comprises the chemical elements in percentage by mass: 0.22 to 0.30 percent of C, 0.1 to 0.4 percent of Si, 0.5to 1.2 percent of Mn, 0.8 to 1.3 percent of Cr, 0.6 to 1.2 percent of Mo, 0.02 to 0.06 percent of Nb, 0.2 to 0.3 percent of V, 0.02 to 0.06 percent of Ti, 0.0015 to 0.005 percent of B, 0.01 to 0.05 percent of Al, 0.0005 to 0.005 percent of Ca, and the balance Fe and inevitable impurities. The invention further discloses a manufacturing method of the thick-wall high-strength high-toughness oil casing pipe. The manufacturing method of the thick-wall high-strength high-toughness oil casing pipe comprises the steps of (1) smelting and continuous casting; (2) perforating and continuous rolling; and(3) adopting heat treatment processes for two times, wherein during heat treatment for the first time, a two-phase region quenching process is adopted, so that austenite formed by dispersed distribution of a two-phase region is quenched so as to form martensite, and other tissues keep as bainite; and during heat treatment for the second time, a process of water quenching and tempering after complete austenitizing is adopted. The thick-wall high-strength high-toughness oil casing pipe provided by the invention is low in cost, has high strength and high toughness at the same time, and can meetthe demand of an oil field on high-performance oil well pipes.

Owner:BAOSHAN IRON & STEEL CO LTD

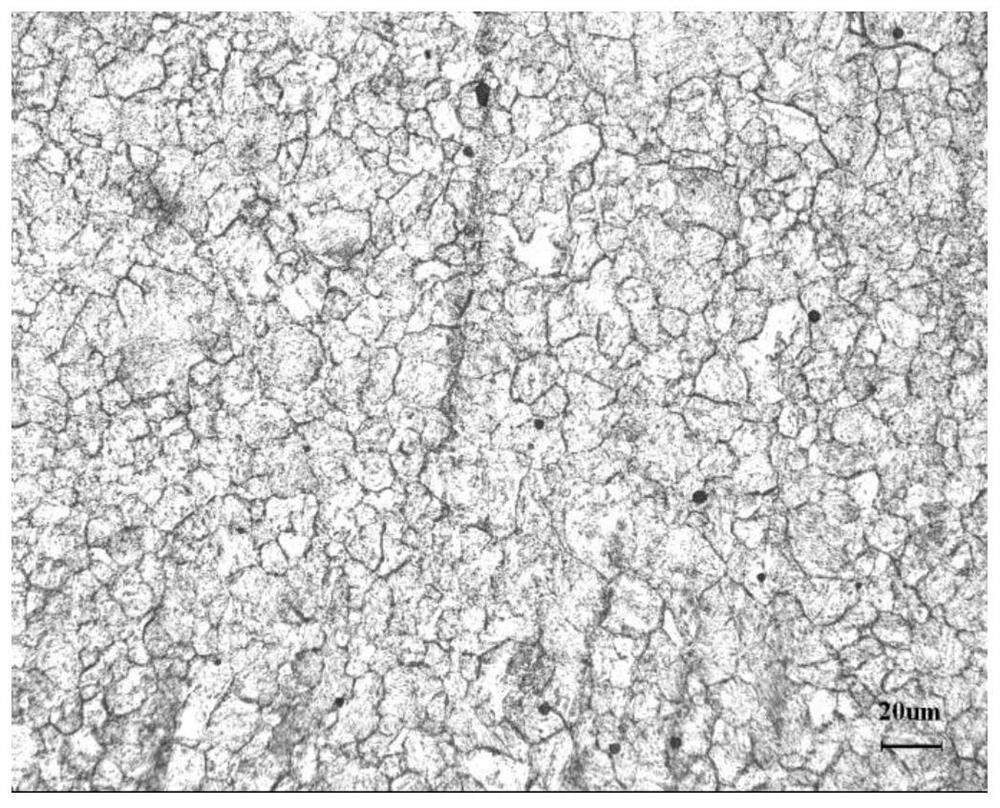

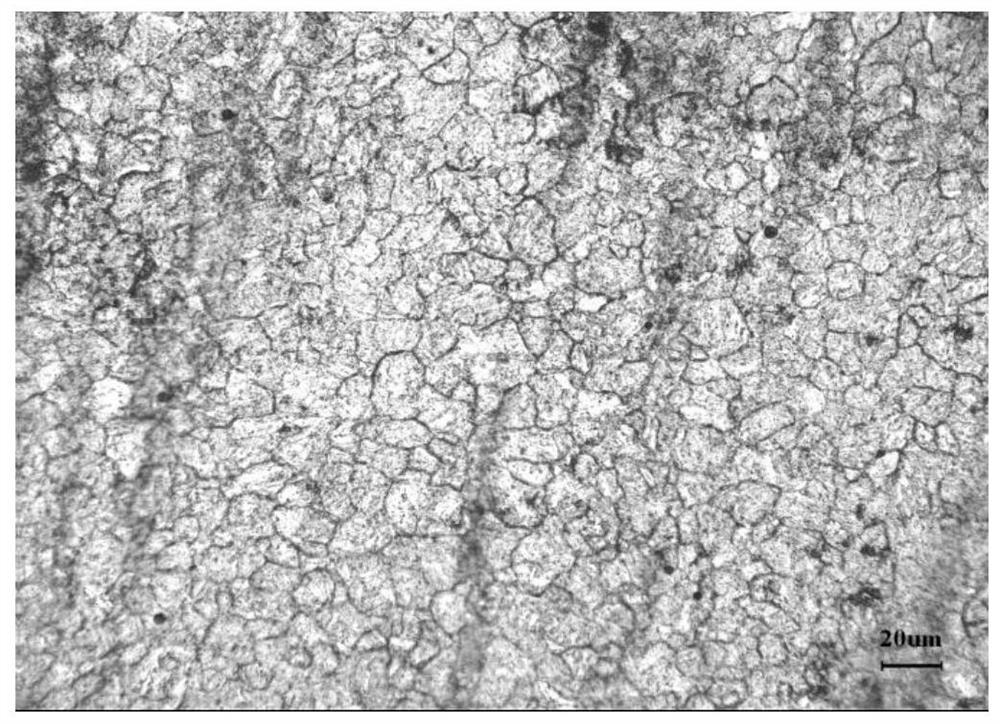

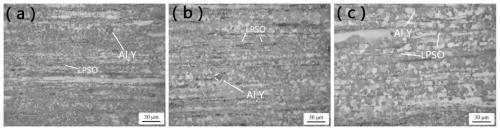

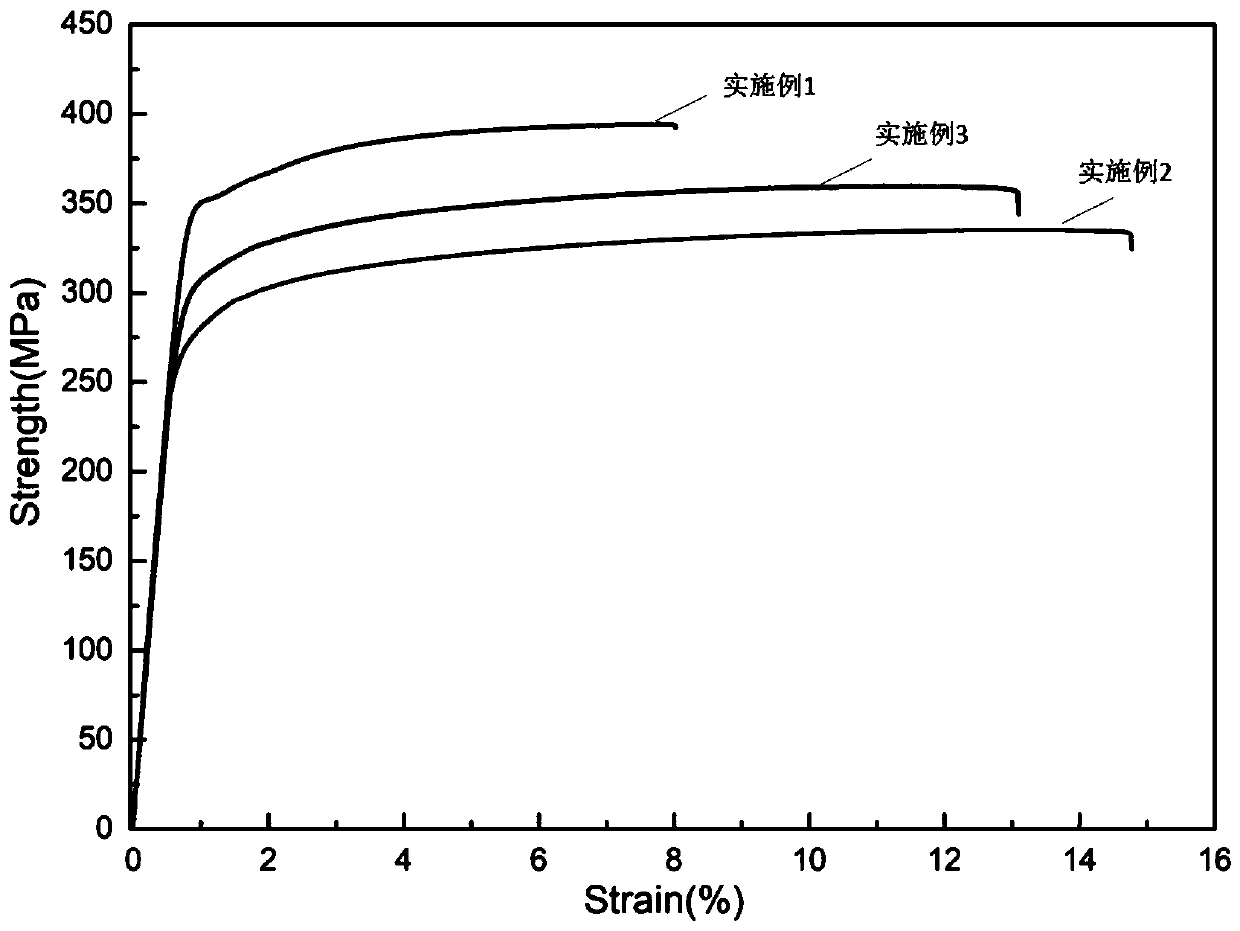

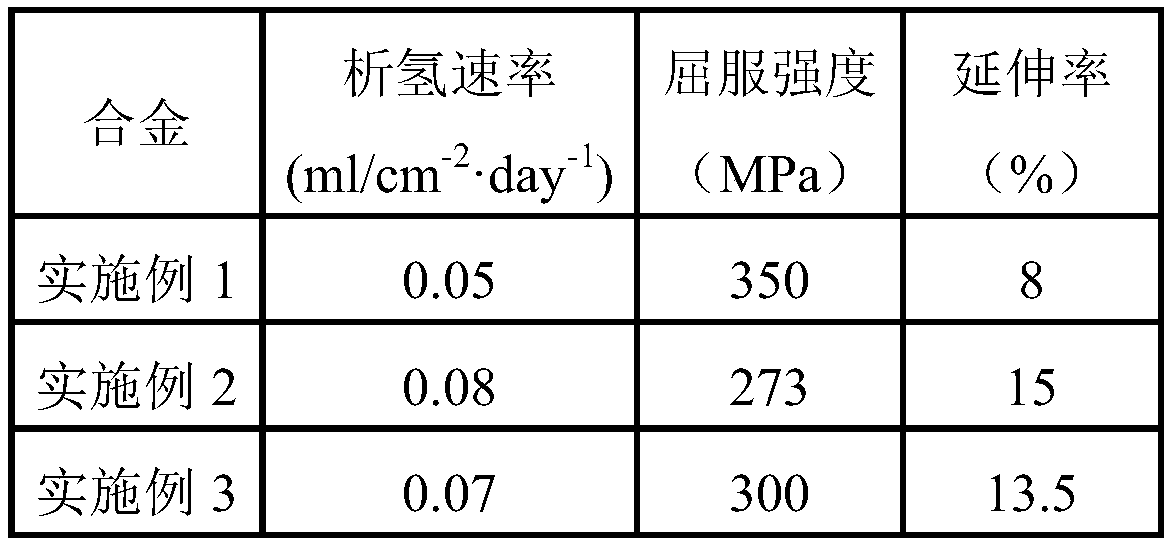

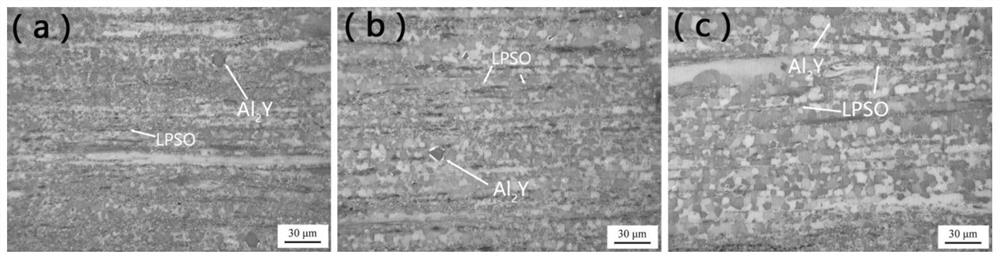

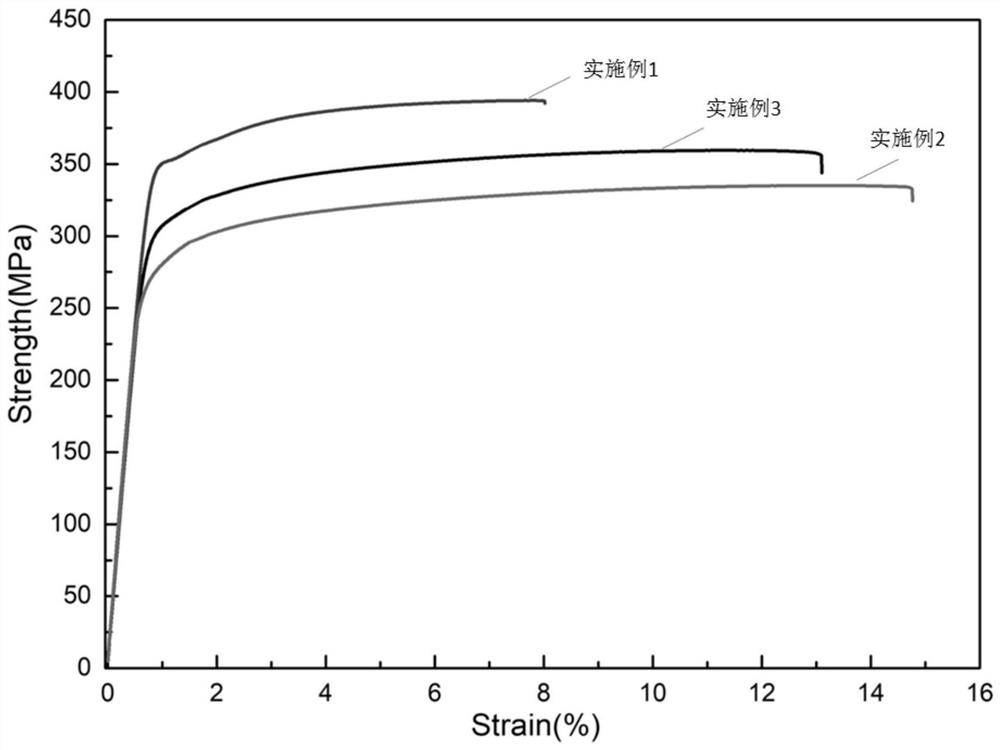

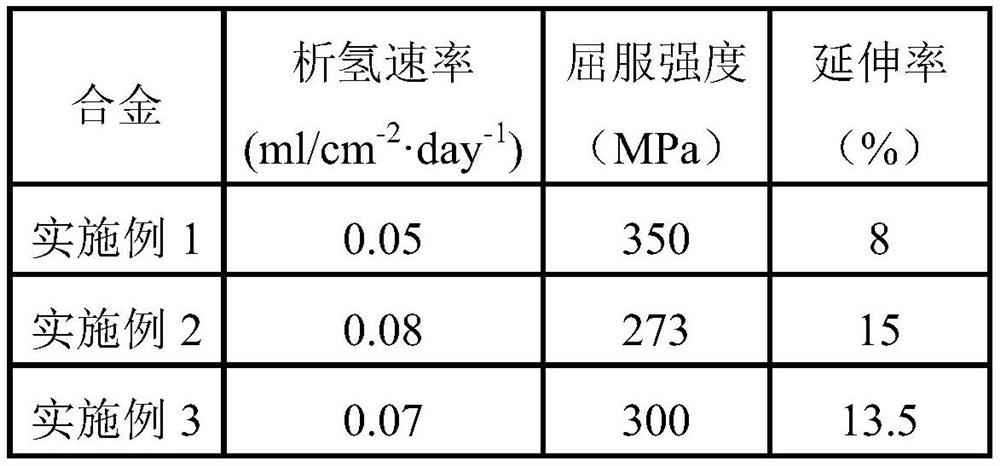

High-strength and high-corrosion-resistance ternary magnesium alloy and preparation method thereof

The invention relates to a high-strength and high-corrosion-resistance ternary magnesium alloy and a preparation method thereof. The magnesium alloy comprises, by mass, 8-12 wt% of Y, 0.6-3 wt% of Aland the balance Mg. The method comprises the following steps that (1) under a protective atmosphere, a Mg-Y intermediate alloy, an aluminum ingot and a magnesium ingot are prepared to prepare a magnesium alloy melt; (2) under the protective atmosphere, the magnesium alloy melt stands after being stirred, refining and degassing, and slag removal are carried out, and the magnesium alloy melt standsagain and preserves heat to obtain magnesium alloy liquid; (3) the magnesium alloy liquid is cast into a mold under the protective atmosphere to form a cast ingot; and finally, the high-strength and high-corrosion-resistance ternary magnesium alloy is obtained through the above three steps. Compared with the prior art, the method has the advantages of being good in corrosion resistance, high in mechanical property, low in sensitivity to impurity iron elements and simple in preparation process.

Owner:SHANGHAI JIAO TONG UNIV

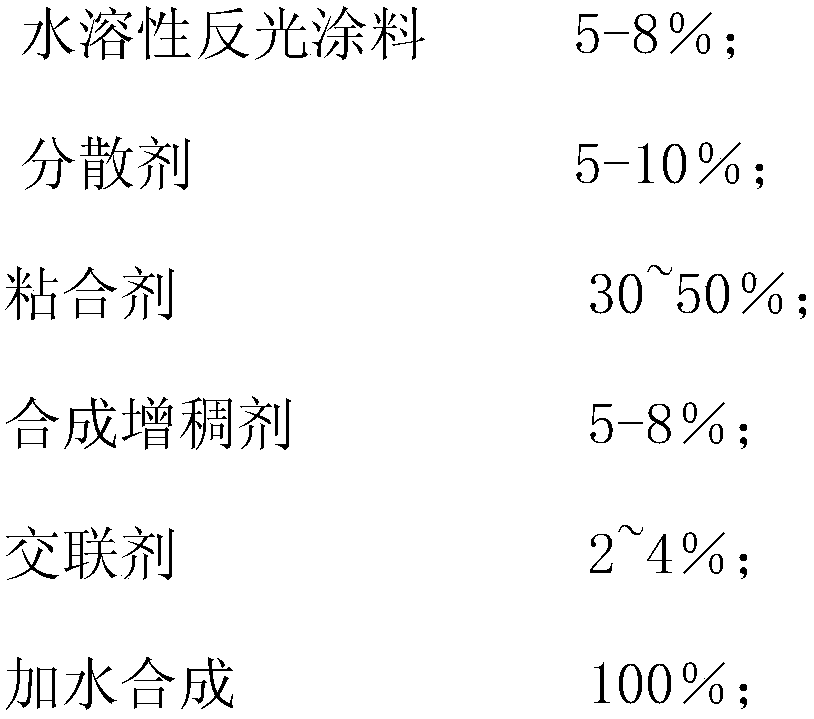

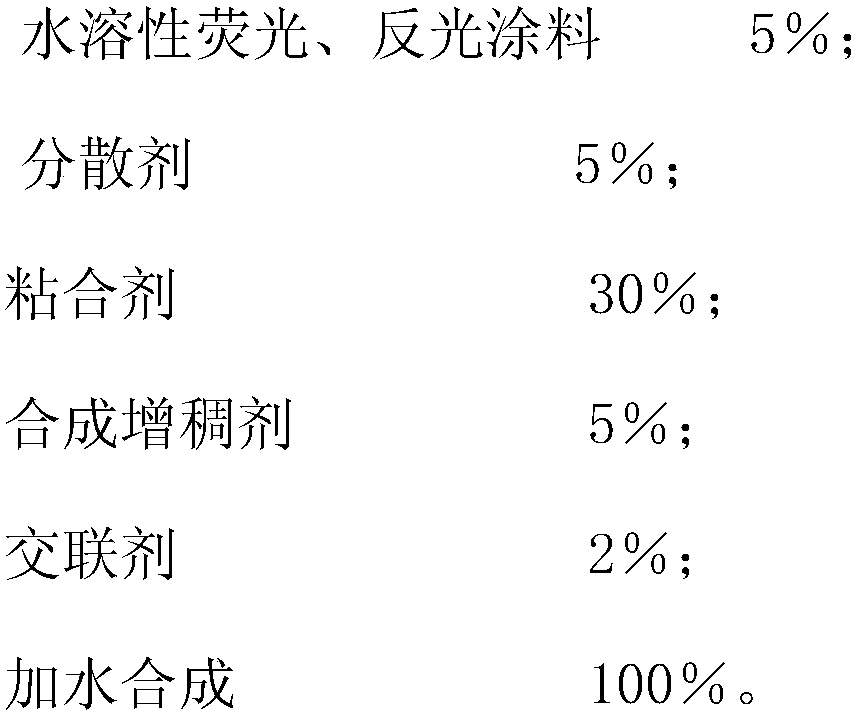

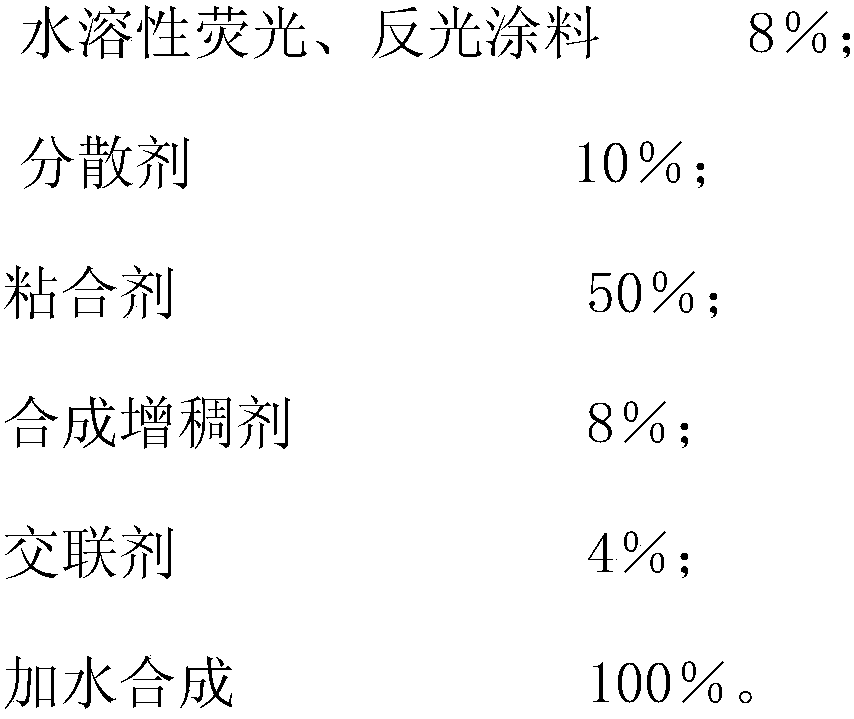

Method for producing high-strength and high-modulus fluorescent and reflective polyethylene cable

The invention discloses a method for producing a high-strength and high-modulus fluorescent and reflective polyethylene cable. Ultrahigh molecular weight polyethylene filaments are woven to form a rope, the rope is padded in a slurry containing fluorescent and reflective powder, the padded rope is reeled and then is dried, and the dried rope is baked to make the fluorescent and reflective powder uniformly distributed on the surface of the rope. The method includes the following steps: fluorescent and reflective slurry preparation, ultrahigh molecular weight polyethylene filament, weaving for forming the rope, padding in the fluorescent and reflective slurry, reeling, drying and baking. The high-strength, anti-corrosion, high-visibility and high-warning rope is formed in the invention, andcan catch the attention of passing ships at night in bad weather in order to reduce safety accidents and increase the visibility of rescue search. The high-strength and high-modulus fluorescent and reflective polyethylene cable has the advantages of extremely stable physical and chemical properties, strong environmental adaptability, long service life and small particles. The above fluorescent andreflective material is processed to form a water-soluble coating, and the water-soluble coating can be uniformly dispersed and applied on the rope.

Owner:IANGSU COLLEGE OF ENG & TECH

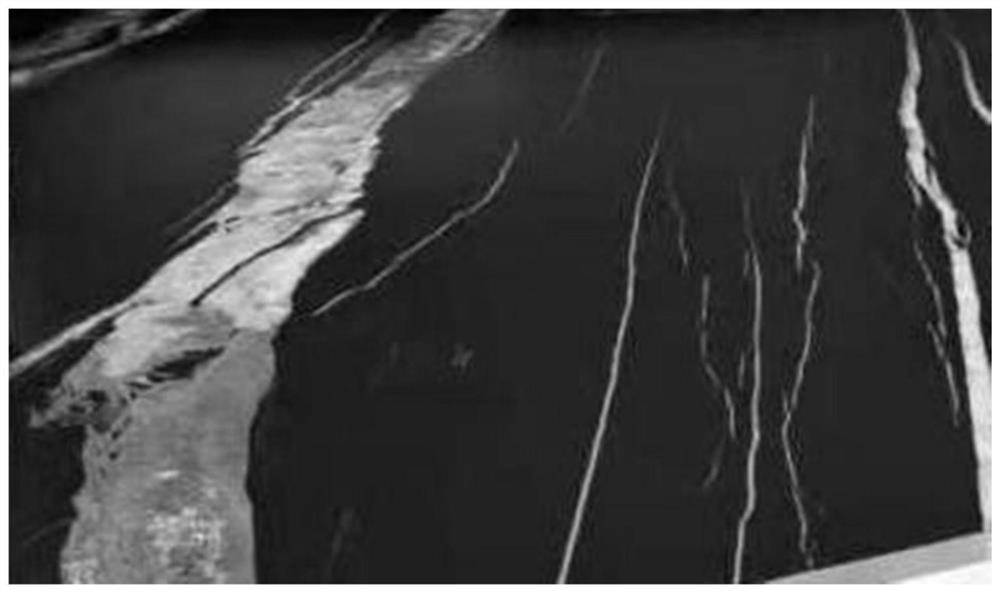

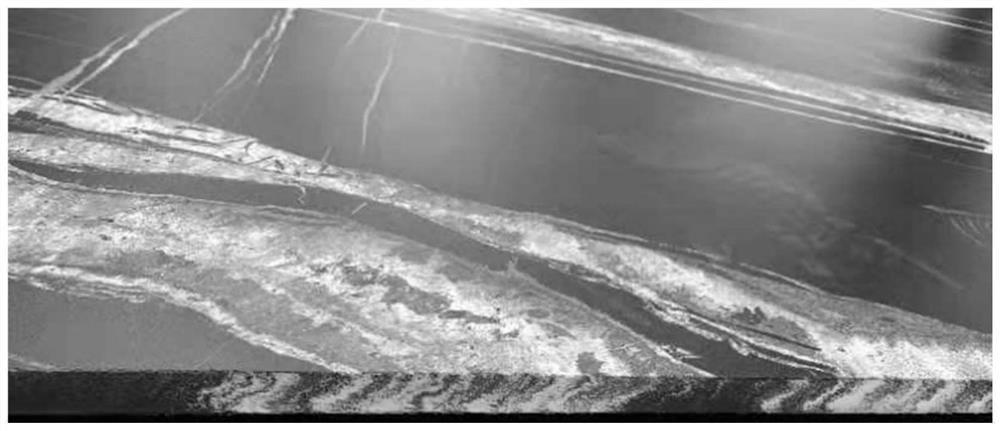

Super-thick rock plate as well as preparation method and application thereof

ActiveCN113121199ALow loss on ignitionImprove oxidation capacityCovering/liningsCeramic materials productionCellulosePhosphate

The invention discloses an ultra-thick rock plate and a preparation method and application thereof. The ultra-thick rock plate comprises a green body layer and a glaze layer, the green body layer comprises bentonite, kaolin, porcelain sand, sand powder, aluminum powder, wollastonite, feldspar and green body additives, and the green body additives comprise phosphate, humate, silicate and cellulose salt. The mass ratio of the bentonite to the kaolin is (1-2.5): (1-2). The bentonite is adopted to replace part of kaolin, so that the ignition loss is reduced, and the oxidation performance and hardness are improved. Phosphate, humate, silicate and cellulose salt are adopted as green body additives, the defect that the strength of the green body is reduced due to reduction of kaolin is overcome, and the product performance and the technological requirements of the production process are better met.

Owner:广东金牌陶瓷有限公司

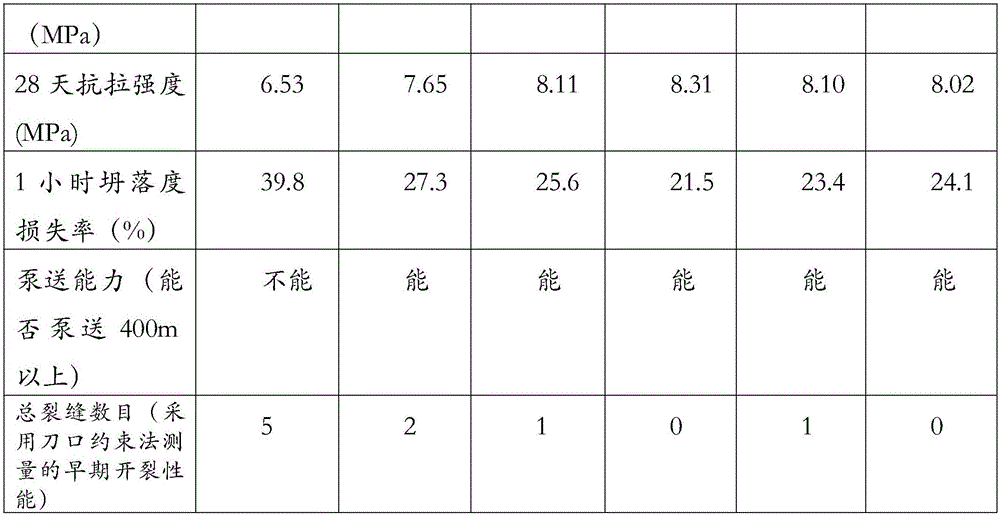

High-strength high-performance concrete

The invention relates to high-strength high-performance concrete. The concrete is prepared from the following components in parts by weight: 200-240 parts of cement, 20-30 parts of coal ash, 500-750 parts of sand, 800-1100 parts of rubbles, 10-30 parts of hemihydrate gypsum, 40-55 parts of kaolin, 20-40 parts of serpentine powder, 20-40 parts of zirconium silicate, 20-30 parts of polycarboxylene based superplasticizer, and 100-150 parts of water. The high-strength high-performance concrete disclosed by the invention ha the advantages of being high in strength, good in durability, good in construction liquidity, and hard to produce cracks, and the concrete is suitable for extensive popularization and application.

Owner:JINAN CHANGXING CONSTR GRP

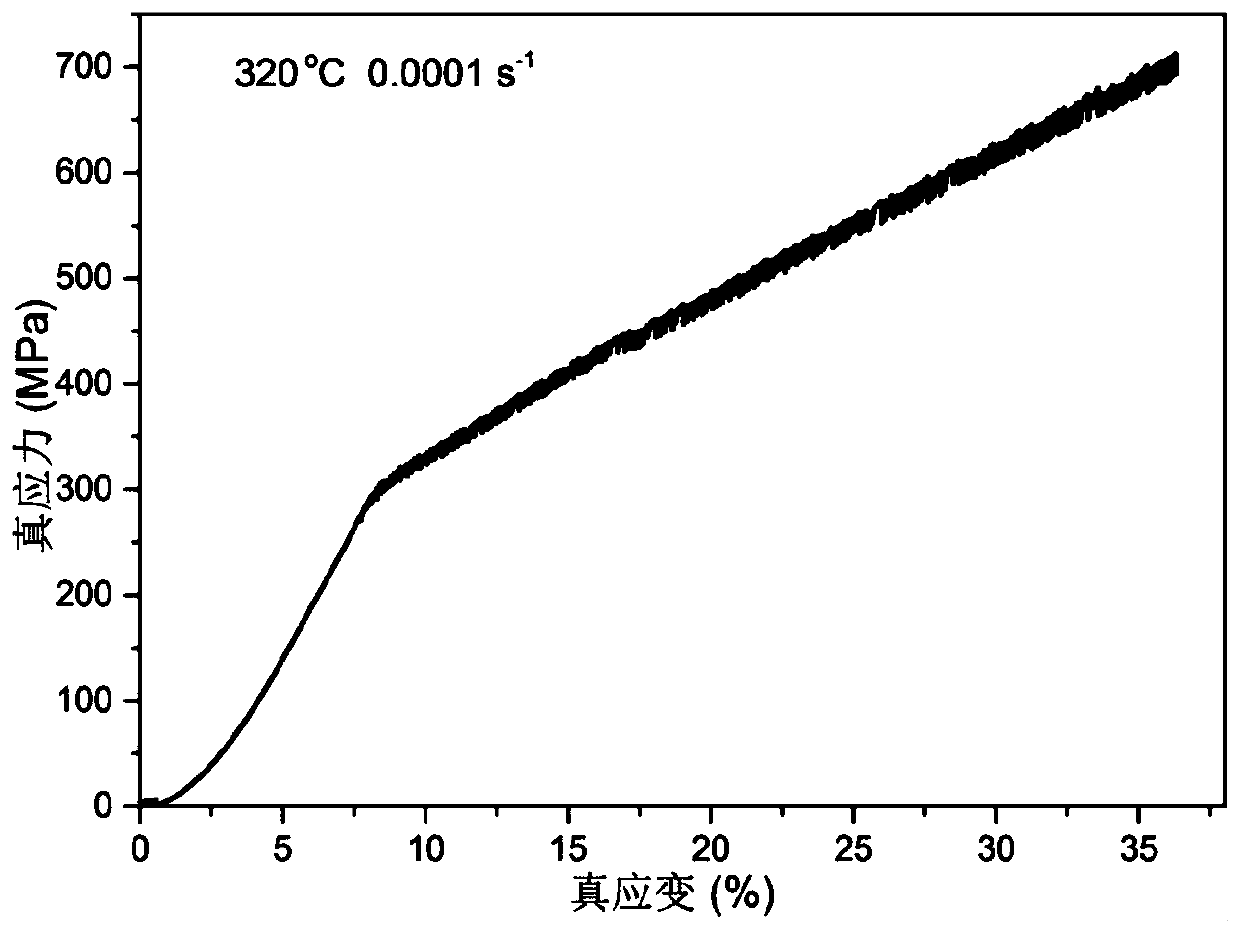

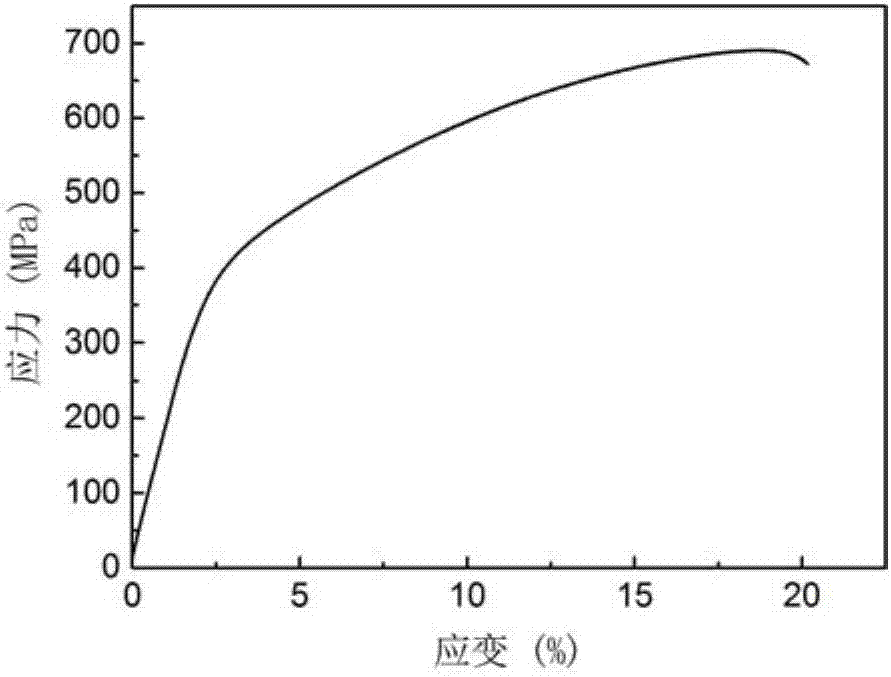

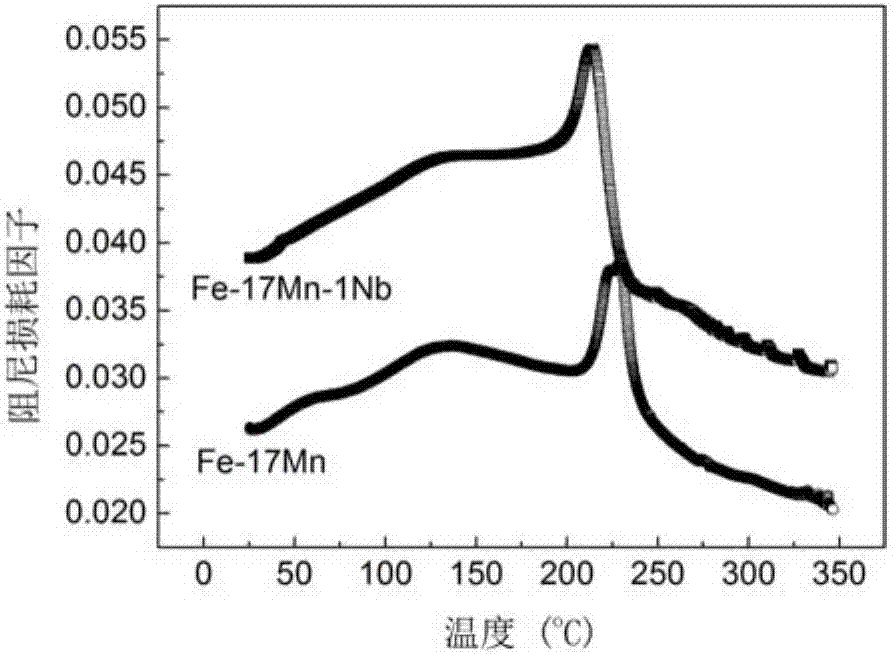

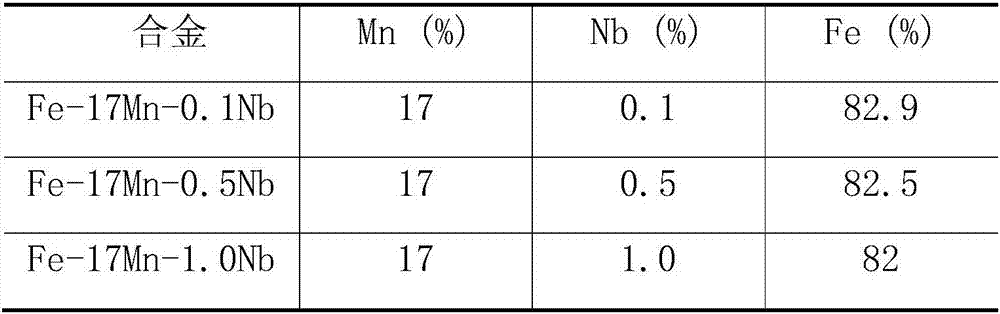

Nb-containing iron-manganese-based damping alloy and preparation method thereof

ActiveCN106282786BHigh strengthHigh damping characteristicsFurnace typesHeat treatment furnacesManganeseRoom temperature

The invention provides an Nb-containing ferrum-manganese-based damping alloy and a preparation method thereof. The alloy is composed of 17% by mass of Mn, 0.1-1% by mass of Nb and the balance of Fe, totaling 100%. The preparation method comprises the following steps of: firstly weighing the raw materials in percentages by mass; performing vacuum arc melting to obtain cast ingots; and then performing homogeneous thermal treatment, hot-rolling, sizing and solid solution treatment successively on the cast ingots. The maximum damping loss factor tandelta of a Fe-17 alloy is increased to 0.055, the temperature interval of high damping (tandelta is greater than 0.03) is increased to 25-330 DEG C, and meanwhile, a good mechanical property (the room temperature tensile strength reaches 691-834MPa and the ductility is 15.7-22.6%) is maintained at the same time. The raw materials are low in price, the thermal processing performance is excellent, the preparation method is relatively simple, and the alloy has the characteristics of high strength and high damping.

Owner:HARBIN ENG UNIV

A kind of high strength and high corrosion resistance ternary magnesium alloy and preparation method thereof

Owner:SHANGHAI JIAOTONG UNIV

High-strength and high-adhesion adhesive tape

The invention discloses a high-strength and high-adhesion adhesive tape. The high-strength and high-adhesion adhesive tape comprises a reinforcement layer, an adhesive layer, a substrate layer and a rubber layer which are stacked in sequence from top to bottom, wherein the reinforcement layer is a nylon thin film layer; the substrate layer is a polycarbonate fiber fabric layer; the rubber layer isa mixed adhesive layer of butyl rubber and chloroprene rubber; the polycarbonate fiber fabric layer and the nylon thin film layer are adhered through an adhesive to form a whole body. The high-strength and high-adhesion adhesive tape disclosed by the invention is simple in preparation and structure; the adhesion adhesive tape has good sealing performance, high strength and high impact resistanceand also has extremely good adhesion performance.

Owner:CHANGSHU CHANGJIANG TAPE

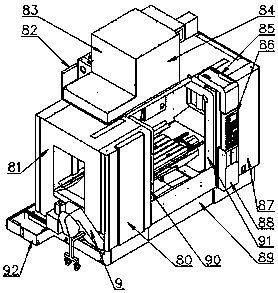

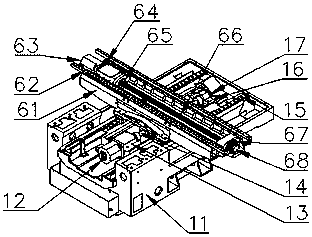

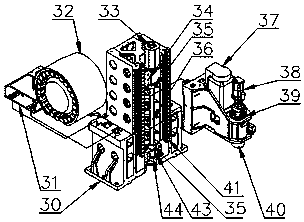

A high-strength and large-table CNC machining center

ActiveCN106112565BReduce thermal shiftIncrease powerLarge fixed membersPositioning apparatusNumerical controlMotor drive

The invention discloses a high-strength and large-workbench numerical control machining center. The structural performance of a base, an upright post, a bed saddle, a workbench and a spindle body are improved, so that power and torsion of a spindle motor driving system are increased; stress backflow analysis between the design span of the bed saddle and the workbench is strengthened, and the size of the workbench and the stroke of an X axis are increased, so that processing conditions are diversified and extended, and the high-strength and high-rigidity mechanical structure of a machine table and the heavy-cutting and high-stability processing conditions are comprehensively enhanced.

Owner:GOODWAY MACHINE WUJIANG CORP

A kind of high-strength high-plasticity low-carbon medium manganese trip steel and preparation method thereof

ActiveCN112853224BHigh strengthHigh strength high strengthFurnace typesHeat treatment process controlTRIP steelChemical composition

A high-strength, high-plasticity low-carbon medium-manganese TRIP steel and a preparation method thereof belong to the technical field of high-strength and high-plasticity steels. The high-strength and high-plasticity low-carbon medium-manganese TRIP steel includes components and the mass percentages of each component are: C: 0.08-0.16%, Mn: 2.9-4.0%, Si: 0.1-1.5%, Al: 0.01-0.08%, Ti : 0.005~0.04%, P<0.015%, S<0.003%, the balance is Fe and unavoidable impurity elements. Its preparation method adopts the raw materials of the above chemical composition through smelting, casting, forging, hot rolling, and two-step annealing in the two-phase zone. It has high strength, high plasticity, and good impact toughness. The heat treatment process is simple and feasible, and it is easy to realize industrial continuous production.

Owner:NORTHEASTERN UNIV LIAONING

A kind of steel with low yield strength ratio ultra-high strength and high toughness pressure-resistant shell and its preparation method

ActiveCN111705268BHigh strengthImprove plasticityFurnace typesHeat treatment furnacesTemperingMartensite

Owner:NORTHEASTERN UNIV LIAONING

Novel high-temperature-resistant hot inlay material

The invention relates to a novel hot inlay material for inlaying of a metallographic sample and relates to composition design and a curing process of a novel hot inlay material. The hot inlay materialconsists of a mixed liquid, aluminate cement and water. The inlay material consists of the following components in parts by mass: 4-5 parts of the mixed liquid, 13-16 parts of the aluminate cement and 1.5-4 parts of the water. The mixed liquid consists of the following components in parts by mass: 1 part of methyl hexahydrophthalic anhydride, 1 part of methyl nadic anhydride, and 3 parts of an epoxy resin. The curing process is carried out for 24-48 hours at 150-160 DEG C. The hot inlay material prepared according to the formula and the curing process is good in forming, high in hardness, high in strength, good in wear resistance, high in deformation resistance at a high temperature, and still hard and non-deformation at 300 DEG C, and in addition, the operation is easy, the cost is low and environmental friendliness is achieved.

Owner:HARBIN UNIV OF SCI & TECH

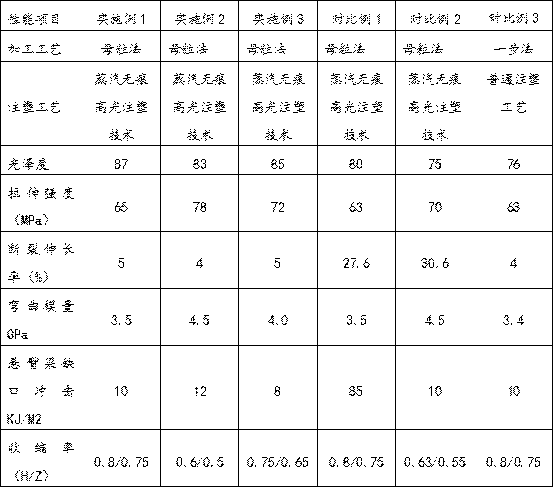

PC/ABS based low-shrinkage high strength and high gloss engineered polypropylene material and preparation method thereof

The invention relates to a PC / ABS based low-shrinkage high strength and high gloss engineered polypropylene material and a preparation method thereof. The material comprises: 65 weight parts of high fluidity polypropylene, 10 weight parts of grafted PP, 5 weight parts of POE, 5 weight parts of PA66 fiber, 15 parts of 5um glass fiber, 1.0 weight part of an anti-glass fiber exposure agent, and 0.3 weight part of an antioxidant. The preparation method mainly includes the following three processes: glass fiber masterbatch manufacturing, polypropylene and masterbatch granulation, and high gloss andtraceless injection molding. An internal mixer or an exhaust twin-screw extruder is adopted in the glass fiber masterbatch manufacturing process. Ultrafine glass fiber and flexible organic fiber areinnovatively used for strengthening, and 5% or more of high grafting rate polypropylene is used as an efficient compatilizer and greatly enhances the compatibility between fiber and polypropylene, also high gloss steam traceless injection molding technology is utilized in the injection molding process to further improve the gloss of the high gloss reinforced polypropylene product, and finally through combined action, the product glass can reach the requirements of high gloss exterior parts. The PC / ABS based low-shrinkage high strength and high gloss engineered polypropylene material provided by the invention is low in cost as the general purpose material PP, but has the gloss, water shrinkage, strength and the like reaching the standards of PC / ABS alloy, ABS, PA and other engineering materials, can be used as a substitute to lower the cost, and has enormous commercial value.

Owner:SHANDONG DAWN POLYMER CO LTD

MIM process for ultrahigh-strength and high-toughness steel parts

The invention discloses an MIM process for ultrahigh-strength and high-toughness steel parts, and belongs to the technical field of metal powder injection molding. The MIM process comprises the following steps of raw material selection, feed preparation, injection molding, catalytic degreasing, thermal degreasing and sintering, solution treatment and aging treatment, Wherein the procedure of thermal degreasing and sintering specifically comprises the step of a green body subjected to catalytic degreasing being sequentially subjected to thermal degreasing, deoxidation and decarbonization and sintering. The MIM process for the ultrahigh-strength and high-toughness steel parts has the characteristics of being simple, convenient, economical and efficient, metal parts which are ultrahigh in strength, high in toughness and high in hardness and have three-dimensional complex shapes can be manufactured in a large scale within a short time, by means of improvement on raw material components and a thermal degreasing and sintering process, the strength, toughness and hardness of the steel parts can be remarkably improved, the requirements of 3C and other industries for high-performance parts can be met, and huge economic benefits are generated.

Owner:SHENZHEN ELEMENT TECH CO LTD

Protecting paint used on polyurea coating and preparation method and construction method for protecting paint

InactiveCN102286244BHigh strengthHigh strength high strengthLiquid surface applicatorsPolyurea/polyurethane coatingsWeather resistancePolyol

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

Novel high-temperature-resistant cold mounting material

The invention relates to an ingredient designing and preparing method of a novel cold mounting material, in particular to a novel cold mounting material for metallographic specimen mounting. The coldmounting material is composed of, by mass, 5-8 parts of dental base acrylic resin liquid, 7-9 parts of dental base acrylic resin powder and 6-15 parts of aluminate cement. The preparation method includes: sufficiently mixing the dental base acrylic resin powder and the aluminate cement, and adding the dental base acrylic resin liquid. The cold mounting material prepared by the method is quick in curing, good in forming effect, high in hardness, wear resistance and deformation temperature and free of deformation after being formed below 200 DEG C.

Owner:HARBIN UNIV OF SCI & TECH

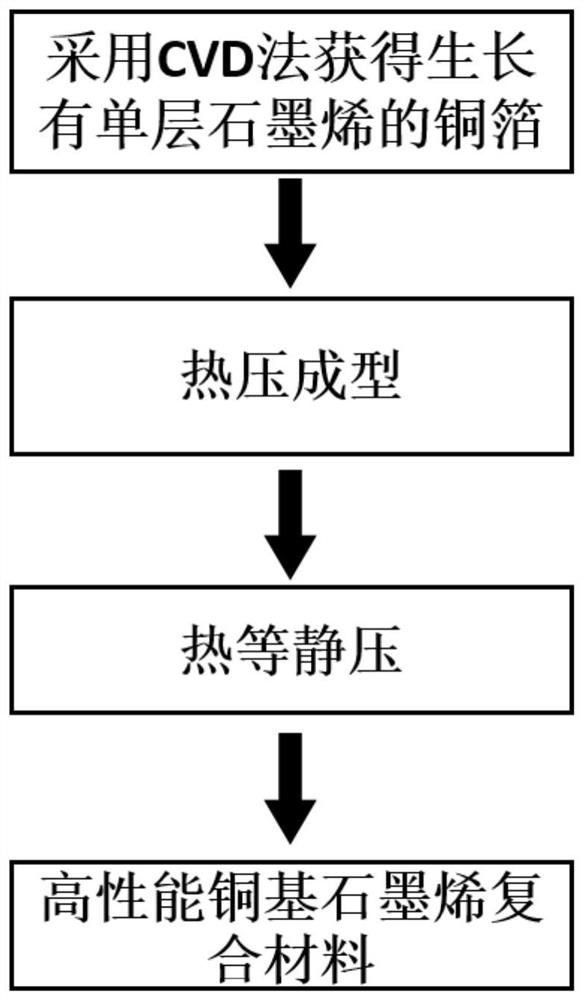

A high-strength and high-conductivity copper-based composite material and its preparation method

ActiveCN111145960BImprove composite effectHigh strengthConductive materialMetal/alloy conductorsComposite effectCopper foil

The invention relates to the field of metal composite materials, in particular to a high-strength and high-conductivity copper-based composite material and a preparation method thereof. The preparation method includes: (1) laminating two or more layers of copper foils deposited with graphene and performing hot pressing to form a graphene-copper composite material; (2) passing an inert gas at 700-900°C The graphene-copper composite material is subjected to hot isostatic pressing densification treatment under a pressure of 80-120 MPa. The metal high-strength and high-conductivity copper-based composite material prepared by the invention has good composite effect and has high strength and high conductivity. In addition, the preparation method has a short process and high efficiency, which is beneficial to reduce production costs and save resources, and is also environmentally friendly and convenient for popularization and application.

Owner:CRRC IND INST CO LTD

A kind of manufacturing method of high strength and high dimensional stability hmls polyester industrial yarn

ActiveCN113046851BGood dimensional stabilityHigh breaking strengthTextile/flexible product manufactureFilament-forming treatmentPolyesterYarn

The invention belongs to the technical field of polyester industrial yarn manufacturing, and in particular relates to a manufacturing method of high-strength and high-dimensional-stability HMLS polyester industrial yarn. In the present invention, conventional polyester chips are subjected to solid-phase polycondensation to form high-viscosity polyester chips, and then the high-viscosity polyester chips are passed through a spinning screw extruder to obtain a high-viscosity polyester melt, which is distributed to each melt through a melt main pipe. Body branch pipe, then enters the spinning assembly through the metering pump and extrudes from the spinneret of the assembly, heated by the heating cylinder, enters the blowing cooling, and then passes through the spinning tunnel; oils the surface of the silk, stretches at room temperature in the first stage, and stretches in the second stage Heat stretching, heat setting at high temperature and constant speed, and finally relaxation and setting, coiling and forming, the total stretching ratio is 1.75-2.20; and winding at 6400-7000 m / min, the polyester industrial yarn produced is strong It is 8.2‑8.5cN / dtex, and the dimensional stability is less than 8.0%. It can be widely used in the fields of light truck and car radial tires, V-belt hard cords, transmission belts, high-grade geogrids, high-end automobile tires, conveyor belts, hose tapes, etc. .

Owner:JIANGSU TAIJI IND NEW MATERIALS CO LTD

A kind of ultra-high-strength, high-toughness, high-conductivity copper-nickel-tin alloy and preparation method thereof

The invention provides an ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy which contains nickel, tine, yttrium, niobium, scandium and cerium elements. The total mass of theyttrium, niobium, scandium and cerium elements is less than or equal to 0.5 percent of the mass of the copper-nickel-tin alloy. The copper-nickel-tin alloy has high strength, toughness and conductivity, and is wide in application range. The invention further provides a preparation method of the copper-nickel-tin alloy. The preparation method of the copper-nickel-tin alloy concretely comprises thesteps of preparing materials according to the mass percent of element compositions, and adopting a gas atomization method for preparing to obtain alloy powder; adopting hot isostatic pressure sintering on the alloy powder to obtain a copper-nickel-tin alloy ingot blank; and carrying out solution treatment and warm deformation strengthening treatment on the copper-nickel-tin alloy ingot blank so as to obtain the ultrahigh-strength high-toughness high-conductivity copper-nickel-tin alloy. According to the preparation method, multiple compound factor strengthening and toughening copper alloys are implemented and utilized, and the obtained copper-nickel-tin alloy has the characteristics of refined crystalline strengthening, strain strengthening, dispersion strengthening and precipitation hardening at the same time so as to obtain high strength, toughness and conductivity.

Owner:湖南高创科惟新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com