Super-thick rock plate as well as preparation method and application thereof

A technology of rock slab and green body layer, which is applied in the field of ultra-thick rock slab and its preparation, which can solve the problems of insufficient strength of ceramic slabs, poor thermal stability, and large firing shrinkage, so as to avoid the reduction of green body strength , good thermal stability, good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

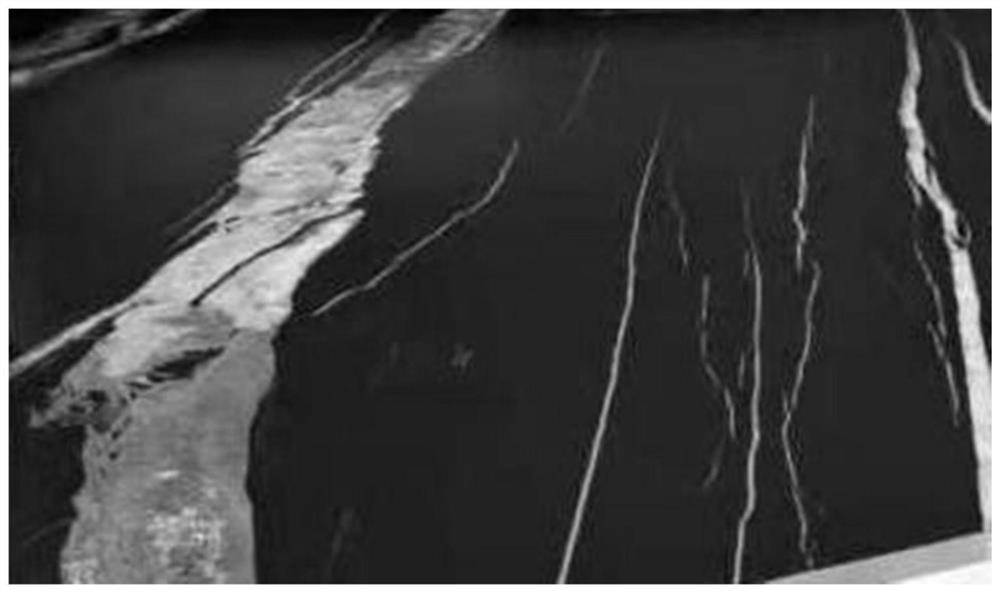

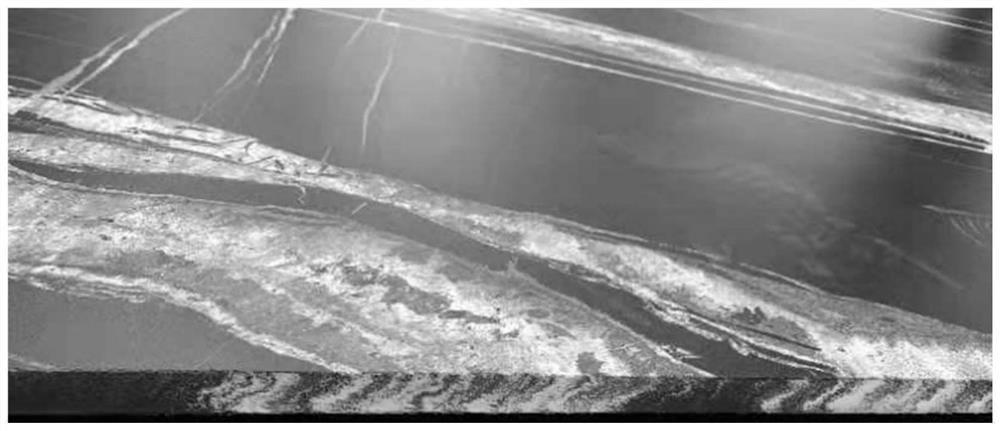

Image

Examples

Embodiment 1

[0051] The rock plate of the present embodiment consists of a billet layer and a glaze layer, and the green body layer consists of a weight percentage of raw materials: 18% bentonite, 13% calcined kaolin, 18% porcelain sand, 10% aluminum powder, 11% silicon Limestone, 10% long stone, 18% sand powder, 0.5% sodium hexose sodium, 0.5% sodium oxate, 0.5% water glass (900 degrees), 0.5% hydroxymethylcellulose sodium.

[0052] According to the mass percentage, the chemical composition of the billet raw material is: 62.4% silica, 21.5% alumina, 4.2% potassium oxide, 1.0% sodium oxide, 3.8% calcium oxide, 0.8% magnesium oxide, 0.3% iron oxide, 5% burning.

[0053] The glazed layer is divided into a glazed underlayer, a pattern layer, and a glazed surface layer. The glazed bottom layer is uniformly covered on the front surface of the billet layer, the pattern layer is printed on the upper surface of the glaze surface, and the glaze surface layer is covered in the pattern layer and glaze. U...

Embodiment 2

[0061] The rock plate of the present embodiment is composed of a blank layer and a glazed layer, and the blank layer consists of a weight percentage of raw materials: 13% bentonite, 20% calcined kaolin, 16% porcelain sand, 10% aluminum powder, 11% silicon Graystone, 10% long stone, 18% sand powder, 0.3% sodium hexose sodium, 0.7% otter sodium sodium, 0.5% water glass (900 degrees), 0.5% hydroxymethylcetulose sodium.

[0062] According to the percentage of mass, the chemical composition of the billet raw material is: 62.6% silica, 22.05% alumina, 4.1% potassium oxide, 1.0% sodium oxide, 3.3% calcium oxide, 0.6% magnesium oxide, 0.35% iron oxide, 6% burning.

[0063] The glaze layer of the present embodiment is consistent with the first embodiment.

[0064] The preparation method of the rock board is:

[0065] (1) Prepreatment of bentonite, calcined kaolin, porcelain sand, aluminum powder, silica grayite, longite, sand powder, sodium hexamphosphate, sodium oxide, water glass (900 de...

Embodiment 3

[0069] The rock plate of the present embodiment is composed of a blank layer and a glaze layer, and the billet layer consists of a weight percent raw material: 21.7% bentonite, 11.3% calcined kaolin, 16% porcelain sand, 10% aluminum powder, 11% silicon Graystone, 10% long stone, 18% sand powder, 0.7% sodium sodium phosphate, sodium 0.7% oxate, 0.7% water glass (900 degrees), 0.3% hydroxymethylcetulose sodium.

[0070] According to the percentage of mass, the chemical composition of the billet layer raw material is: 65.4% silica, 21.5% alumina, 4.0% potassium oxide, 1.0% sodium oxide, 3.7% calcium oxide, 0.8% magnesium oxide, 0.3% iron oxide, 3.3% of the burner.

[0071] The glaze layer of the present embodiment is consistent with the first embodiment.

[0072] The preparation method of the rock board is:

[0073] (1) Prepreatment of bentonite, calcined kaolin, porcelain sand, aluminum powder, silicahydrate, longite, sand powder, add sodium trimophosphate, sodium humid acid, water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com