A white fast setting rapid hardening high belite sulfoaluminate cement clinker, its application and its production process

A special sulfoaluminate and cement clinker technology, applied in the field of building materials, can solve the problems of low early strength, low strength, slow coagulation, etc., and achieve the effects of reducing raw material consumption, reducing heat consumption and reducing exhaust gas emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

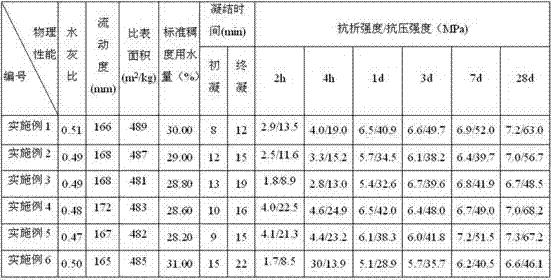

Examples

preparation example Construction

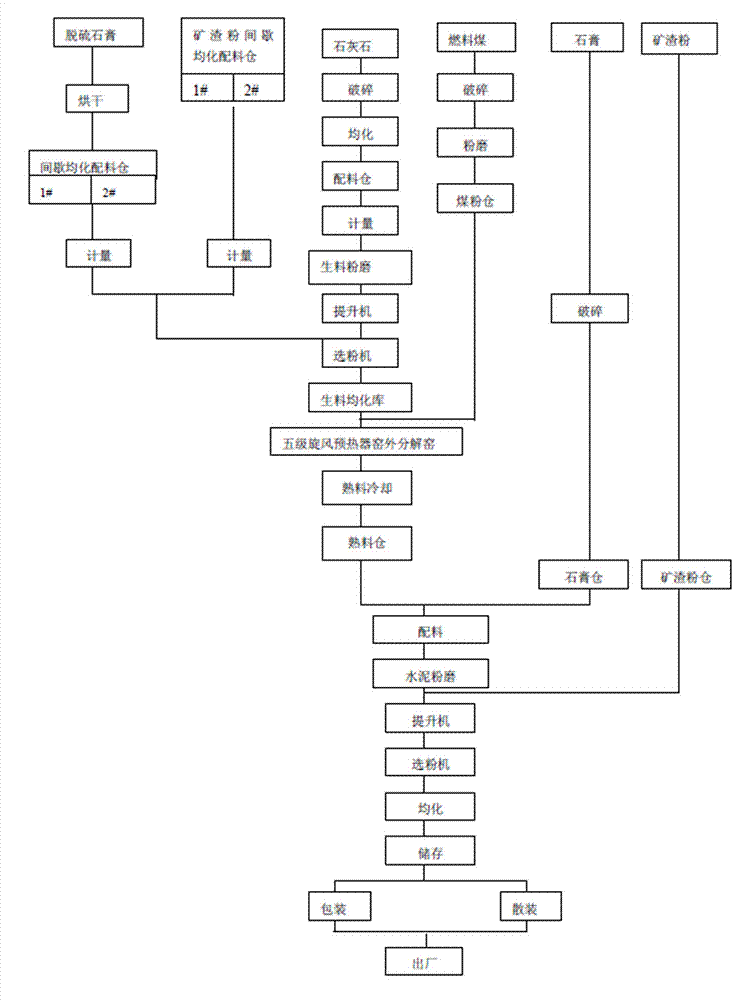

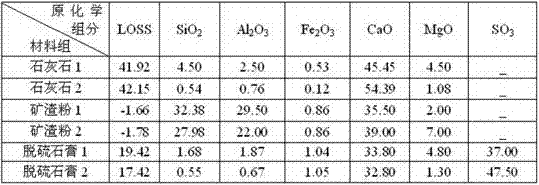

[0068] ① Preparation of raw meal: According to the ratio of raw meal in Table 2, weigh the limestone whose chemical composition is shown in Table 1, put it into the raw meal mill, and then enter the raw meal mill tail elevator; at the same time According to the raw material ratio in Table 2, weigh the slag powder and desulfurized gypsum with the chemical composition shown in Table 1, and transport them to the tail elevator of the raw material mill synchronously with the ground limestone, and then transport the three materials to Powder classifier, after being air-selected and mixed by the powder classifier, the qualified raw meal is transported to the raw meal homogenization warehouse, and the unqualified raw meal is sent back to the raw meal mill for further grinding; after homogenization, the raw meal is sent to the kiln.

[0069] In this step, the qualified powder in slag powder and desulfurized gypsum does not enter the raw meal mill, but directly enters the powder classifi...

Embodiment 45

[0103] The cement corrosion resistance test of the present invention selects the cement of cement embodiment 30 to do the corrosion resistance test, and the test results are shown in Table 10-A and Table 10-B. All test blocks are put into the solution after 7 days of standard maintenance, and the implementation standard: cement sulfate corrosion resistance Quick test method GB / T2420 / 1981; three corrosion resistance coefficients of sodium sulfate, sodium carbonate, and sodium chloride with a concentration of 3%: 1.46, 1.41, and 1.51 respectively; three kinds of cements in 3% magnesium sulfate and 3% magnesium chloride solutions The corrosion resistance coefficients in are all greater than or equal to 1.0, and the corrosion resistance coefficient is extremely high.

[0104] Table 10-A

[0105]

[0106] Table 10-B

[0107]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com