Method for preparing phosphorus-magnesium compound fertilizer by utilizing raffinate and phosphate tailings with high magnesium content

A technology of compound fertilizer and high magnesium phosphorus tail is applied in fertilizer mixture, application, fertilization device and other directions, which can solve the problems of low industrialization value, high cost of impurity removal, and high cost, so as to improve the comprehensive utilization rate of resources and reliable product quality. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] raw material:

[0016] 1) Raffinic acid: w(P 2 o 5 )46.0%, w(MgO)3.0%;

[0017] 2) Phosphorus tailings slag: w(P 2 o 5 ) 5.5%, w (MgO) 16.2%.

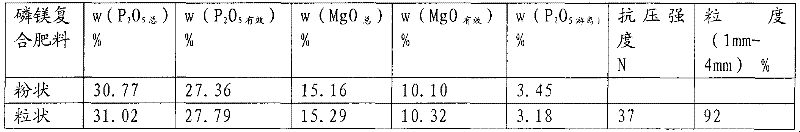

[0018] 1000g of by-product raffinate after purification by wet process phosphoric acid and 1001g of high-magnesium phosphorus tailings slag after drying and crushing are added to the reaction tank with agitator for acidification and mixing reaction, and 1.002g of surfactant dodecylbenzene is added Sodium sulfonate, the reaction temperature is controlled at 40°C during the reaction, and the reaction time is 20min. It is crushed and processed into powdery phosphorus and magnesium compound fertilizer products. The powder is agglomerated into granules by adding water on a disc granulator, dried, cooled, and sieved into a particle size of 1mm-4mm, which is a granular phosphorus-magnesium compound fertilizer product. The product quality analysis results are as follows:

[0019]

Embodiment 2

[0021] raw material:

[0022] 1) Raffinic acid: w(P 2 o 5 ) 44.6%, w (MgO) 5.4%;

[0023] 2) Phosphorus tailings slag: w(P 2 o 5 ) 7.0%, w (MgO) 19.0%.

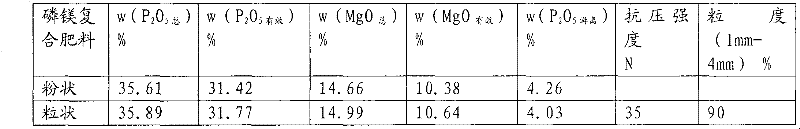

[0024] 1202g of by-product raffinate after purification by wet process phosphoric acid and 1002g of high-magnesium phosphorus tailings slag after drying and crushing are added to the reaction tank with agitator for acidification and mixing reaction, and 0.1002g of surfactant dodecylbenzene is added Sodium sulfonate, the reaction temperature is controlled at 50°C during the reaction, and the reaction time is 15min. After the reaction, the material is unloaded and put into a porcelain plate, dried and cooled to room temperature at 100±5°C, and the material is dry and hardened. It is crushed and processed into powdery phosphorus and magnesium compound fertilizer products. The powder is agglomerated into granules by adding water on a disc granulator, dried, cooled, and sieved into a particle size of 1mm-4mm, which is a gran...

Embodiment 3

[0027] raw material:

[0028] 1) Raffinic acid: w(P 2 o 5 )44.1%, w(MgO)6.0%;

[0029] 2) Phosphorus tailings slag: (P 2 o 5 ) 5.4%, w (MgO) 17.2%.

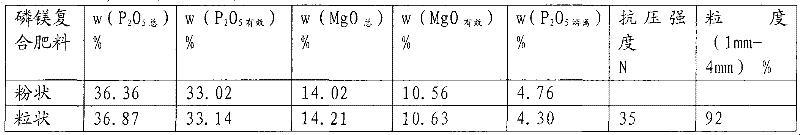

[0030] 1300g of by-product raffinate after purification by wet-process phosphoric acid and 1003g of high-magnesium phosphorus tailings slag after drying and crushing were added to the reaction tank with agitator for acidification and mixing reaction, and 0.1003g of surfactant AES was added. The reaction process The reaction temperature is controlled at 45°C, and the reaction time is 10 minutes. After the reaction, the material is unloaded and put into a porcelain plate, dried and cooled to room temperature at 100±5°C, the material is dry and hardened, and it is crushed and processed into powder Phosphate and magnesium compound fertilizer products. The powder is agglomerated into granules by adding water on a disc granulator, dried, cooled, and sieved into a particle size of 1mm-4mm, which is a granular phosphorus-magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com