Preparation method of Mg-Li matrix Mg-Li-Cu-Ni-Y series bulk amorphous alloy

An amorphous alloy, magnesium-lithium-based technology, applied in the field of preparation of high-strength amorphous alloy materials, can solve the problems of magnesium or lithium burning loss, large deviation, poor performance, etc., to reduce burning loss, reduce critical cooling rate, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

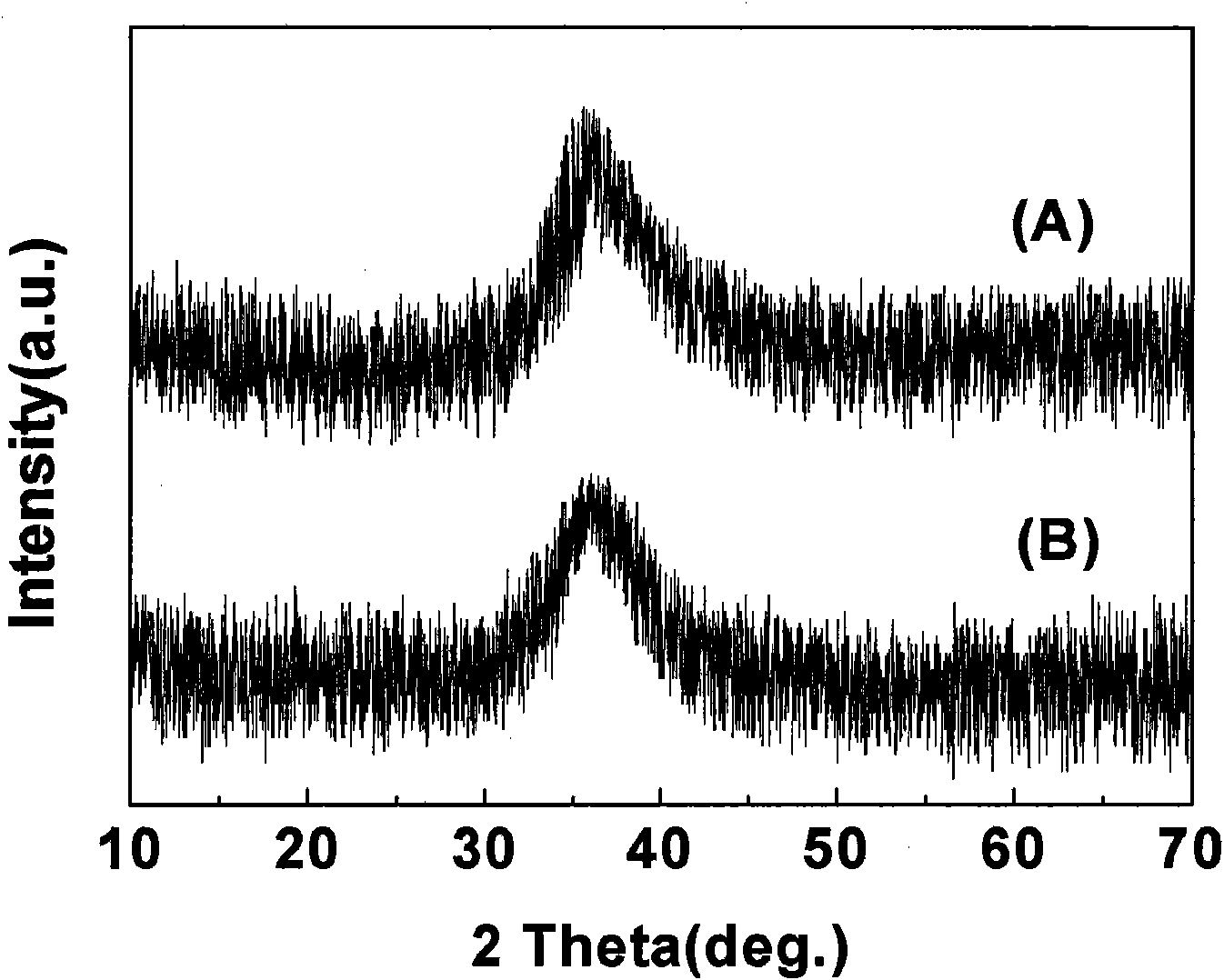

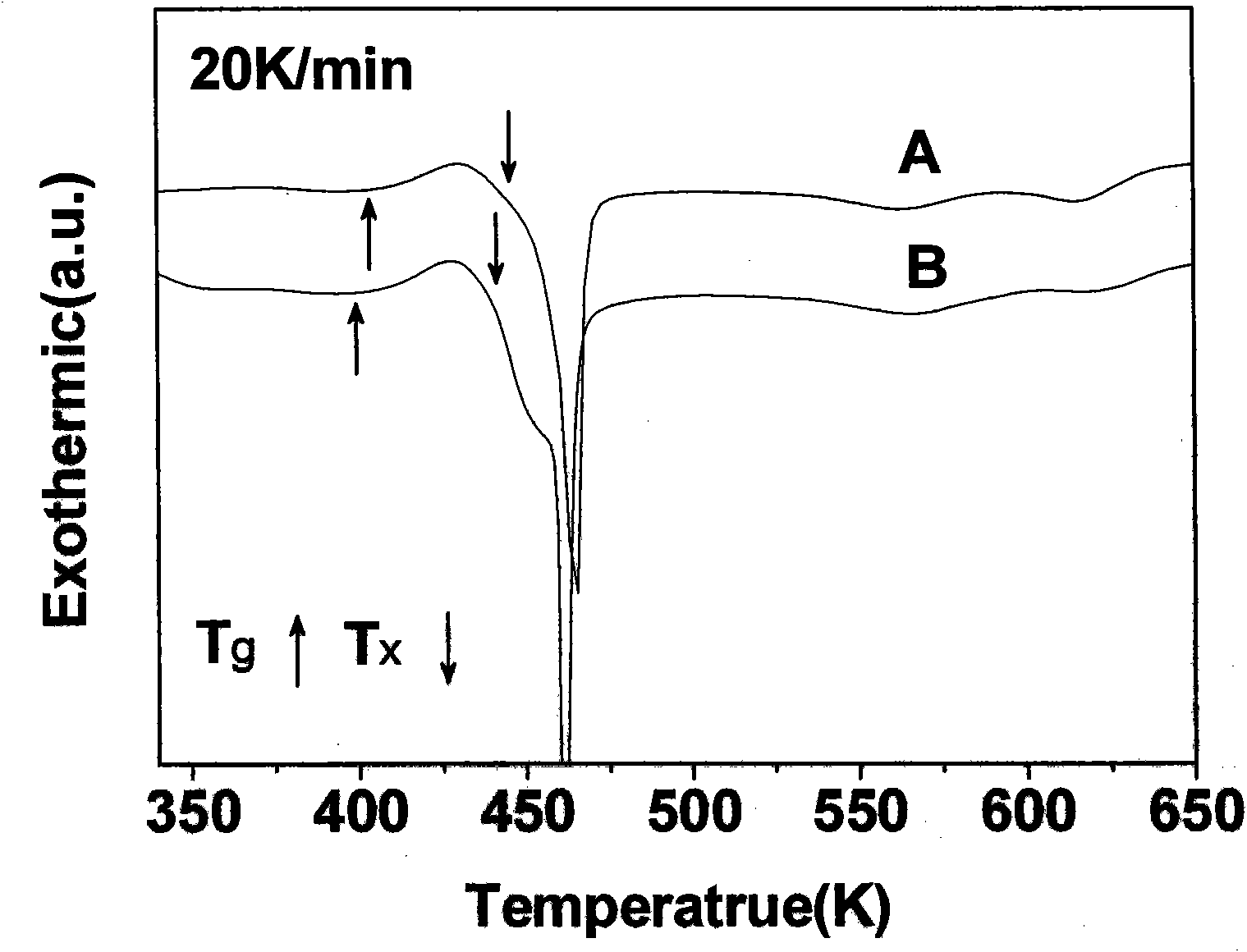

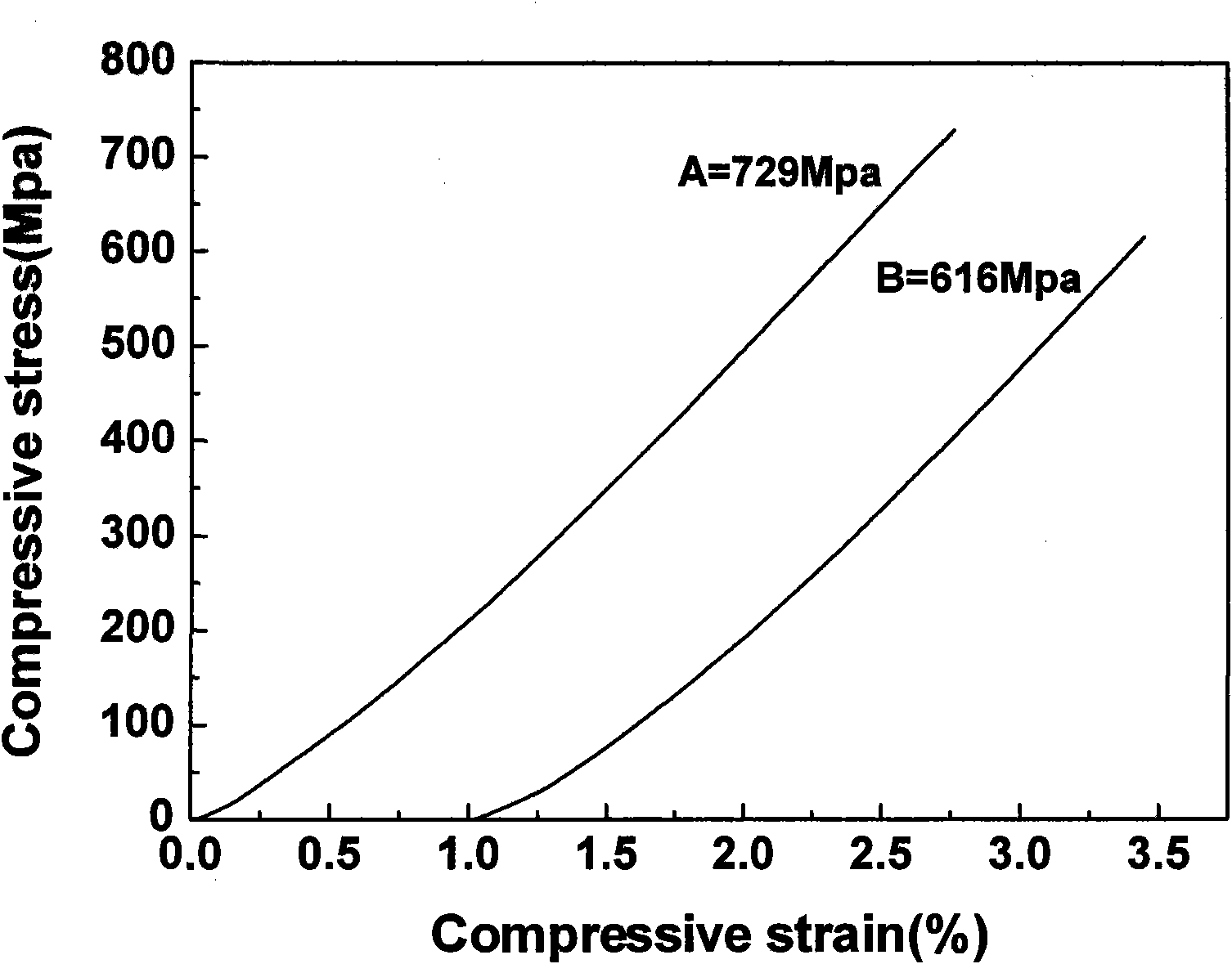

[0018] Choose to prepare x=2, that is, the composition is Mg 65 Li 2 Cu 18 Ni 5 Y 10 The bulk amorphous alloy, the sample diameter is 2mm.

[0019] Step 1: Preparation of master alloy: High-purity magnesium block with a purity of 99.99%, lithium block with a purity of 99.9%, nickel block with a purity of 99.5%, high-purity copper ingot with a purity of 99.8%, high-purity copper ingot with a purity of 99.99% Yttrium block according to composition ratio Mg 65 Li 2 Cu 18 Ni 5 Y 10 Weigh the raw materials; first put the alloy raw materials Cu, Ni, Y into the quartz test tube, place it in the center of the induction coil to avoid contact with the coil, close the furnace door of the intermediate frequency induction melting furnace, and then evacuate to 10 -4 Pa, filled with 10 -2 The argon gas of Pa was repeated three times and the alloy was smelted under the protection of argon gas. In order to make the alloy composition uniform, the alloy was smelted repeatedly 3 to 5 ti...

Embodiment 2

[0025] Choose to prepare x=4, that is, the composition is Mg 65 Li 4 Cu 16 Ni 5 Y 10 The bulk amorphous alloy, the sample diameter is 2mm.

[0026] Step 1: Preparation of master alloy: High-purity magnesium block with a purity of 99.99%, lithium block with a purity of 99.9%, nickel block with a purity of 99.5%, high-purity copper ingot with a purity of 99.8%, high-purity copper ingot with a purity of 99.99% Yttrium block according to composition ratio Mg 65 Li 4 Cu 16 Ni 5 Y 10 Weigh the raw materials; first put the alloy raw materials Cu, Ni, Y into the quartz test tube, place it in the center of the induction coil to avoid contact with the coil, close the furnace door of the intermediate frequency induction melting furnace, and then evacuate to 10 -4 Pa, filled with 10 -2 The argon gas of Pa was repeated three times and the alloy was smelted under the protection of argon gas. In order to make the alloy composition uniform, the alloy was smelted repeatedly 3 to 5 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com