Perlite production equipment

A production equipment and perlite technology, which is applied in the building material production industry and the field of energy conservation and environmental protection, can solve the problems of serious environmental pollution, low output, and high energy consumption, and achieve the goals of improving the working environment, reducing energy consumption, and increasing equipment utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

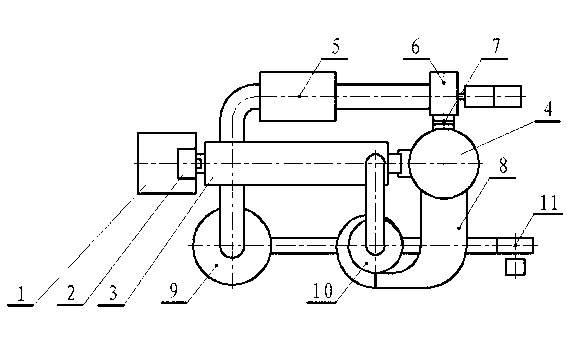

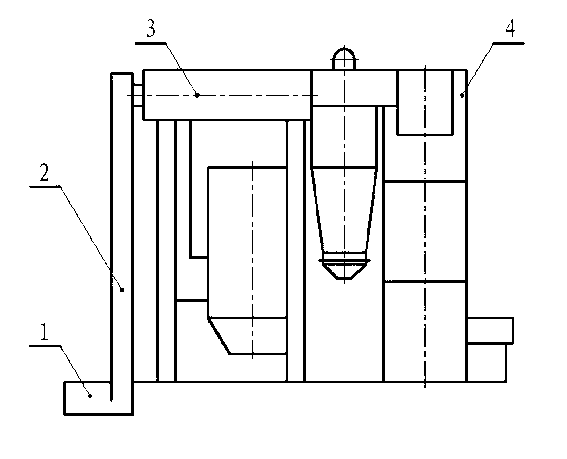

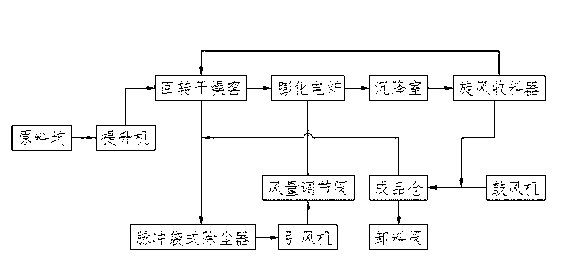

[0010] The present invention is described in detail below in conjunction with accompanying drawing: As shown in the figure, a kind of perlite production equipment mainly consists of raw material pit 1, elevator 2, rotary drying kiln 3, puffing furnace 4, dust collector 5, induced draft fan 6, air volume Regulating valve 7, settling chamber 8, finished product warehouse 9, cyclone receiver 10, blower 11 and joint ventilation pipe; the lower end of the elevator 2 is in the raw material pit 1, the upper end is connected with the rotary drying furnace 3, and the outlet of the rotary drying furnace 3 The feed port is connected to the feed port of the puffing furnace 4, and the rotary drying furnace 3 is also connected to the dust collector 5 by a pipe. 4 is connected to the settling chamber 8, and the settling chamber 8 is connected to the cyclone receiver 10. One side of the cyclone receiver 10 is connected to the finished product warehouse 9 by the air duct, and the other side is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com