Carbon material low-temperature expansion method and preparation method of low-temperature desulphurization and denitration agent for the same

A technology for desulfurization, denitrification, and carbon materials, which is applied in the field of ultrasonic activation to prepare low temperature desulfurization and denitrification agents, and ultrasonic low temperature expansion of carbon materials. The effect of strong catalytic denitration and desulfurization ability, short time and low carbon loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

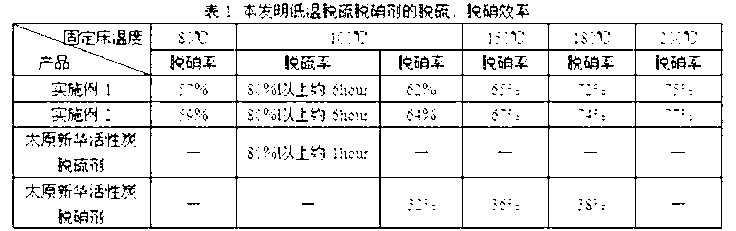

Embodiment 1

[0043] Weigh 60g of dried semi-coke with a particle size of 4-6 mesh in a glass beaker, add the prepared 7mol / L HNO 3 150 mL of the solution was put into a digitally controlled ultrasonic generator filled with distilled water, and ultrasonicated at 60°C, 70°C, and 80°C for 7 minutes at an ultrasonic frequency of 50 kHz and an ultrasonic power of 80 W. Pour out the deacid solution, wash with distilled water ultrasonically for 3 times, then pour 100mL of sodium metavanadate solution with a mass fraction of 4%, and under the conditions of ultrasonic frequency 50kHz and ultrasonic power 80W, the temperature is 60°C, 70°C and 80°C. Sonicate for 25 minutes; then filter and dry at 120°C for 5 hours to obtain a desulfurization and denitrification agent, which is put into a desiccator for use.

Embodiment 2

[0045] Weigh 60g of dry coke with a particle size of 4-6 mesh and put it in a glass beaker, add the prepared 4mol / L HNO 3 150mL of the solution was put into a digitally controlled ultrasonic generator filled with distilled water, and ultrasonicated at 60°C, 70°C, and 80°C for 10 minutes at an ultrasonic frequency of 50kHz and an ultrasonic power of 85W. Pour out the deacid solution, wash it ultrasonically for 3 times with distilled water, then pour 100mL ammonium metavanate solution with a mass fraction of 3%, and under the conditions of ultrasonic frequency 50kHz and ultrasonic power 85W, the temperature is 60°C, 70°C and 80°C. Sonicate for 20 minutes respectively; then filter and dry at 125°C for 4 hours to obtain a desulfurization and denitrification agent, which is put into a desiccator for use.

Embodiment 3

[0047] Weigh 60g of dry back coke with a particle size of 4-6 mesh in a glass beaker, add 150mL of the prepared 6mol / L HCl solution, and then put it into a numerically controlled ultrasonic generator filled with distilled water. Under the conditions of ultrasonic frequency 50kHz and ultrasonic power 90W , respectively at temperatures of 60° C., 70° C. and 80° C. for 7 minutes. Pour out the deacid solution, wash it ultrasonically for 3 times with distilled water, pour 100mL of sodium metavanadate and ammonium metavanadate solution with a mass ratio of 1:1 with a total mass fraction of 3%, and use it under the conditions of ultrasonic frequency 50kHz and ultrasonic power 70W Sonicate at 60°C, 70°C and 80°C for 30 minutes respectively; then filter and dry at 140°C for 3.5 hours to obtain a desulfurization and denitrification agent, which is put into a desiccator for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com