A kind of sulfur reducing additive of hydrocarbon oil cracking product and its preparation and application

A sulfur-reducing aid and the technology of the aid are applied in the field of sulfur-reducing aids for cracked products containing zinc, which can solve the problems of low conversion capacity of heavy oil, low sulfur-reducing performance, poor wear resistance, etc., and achieve good sulfur-reducing effect and good The effect of wear resistance and high conversion rate of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In the preparation method of the sulfur-reducing additive provided by the present invention, in step (4), the slurry obtained in step (3) is spray-dried, and then calcined. The calcining temperature is preferably 500-700° C., and the calcining time is preferably 1-6 hours.

[0024] In order to make the prepared catalyst have better wear resistance and better sulfur reduction effect, in the preparation method of the auxiliary agent, step (2) adds clay to the slurry obtained in step (1), and step (3) Add binder in the slurry that step (2) obtains.

[0025] In the preparation method of the sulfur-reducing additive provided by the present invention, the methods of beating, spray drying and roasting are well known to those skilled in the art, and will not be repeated in the present invention.

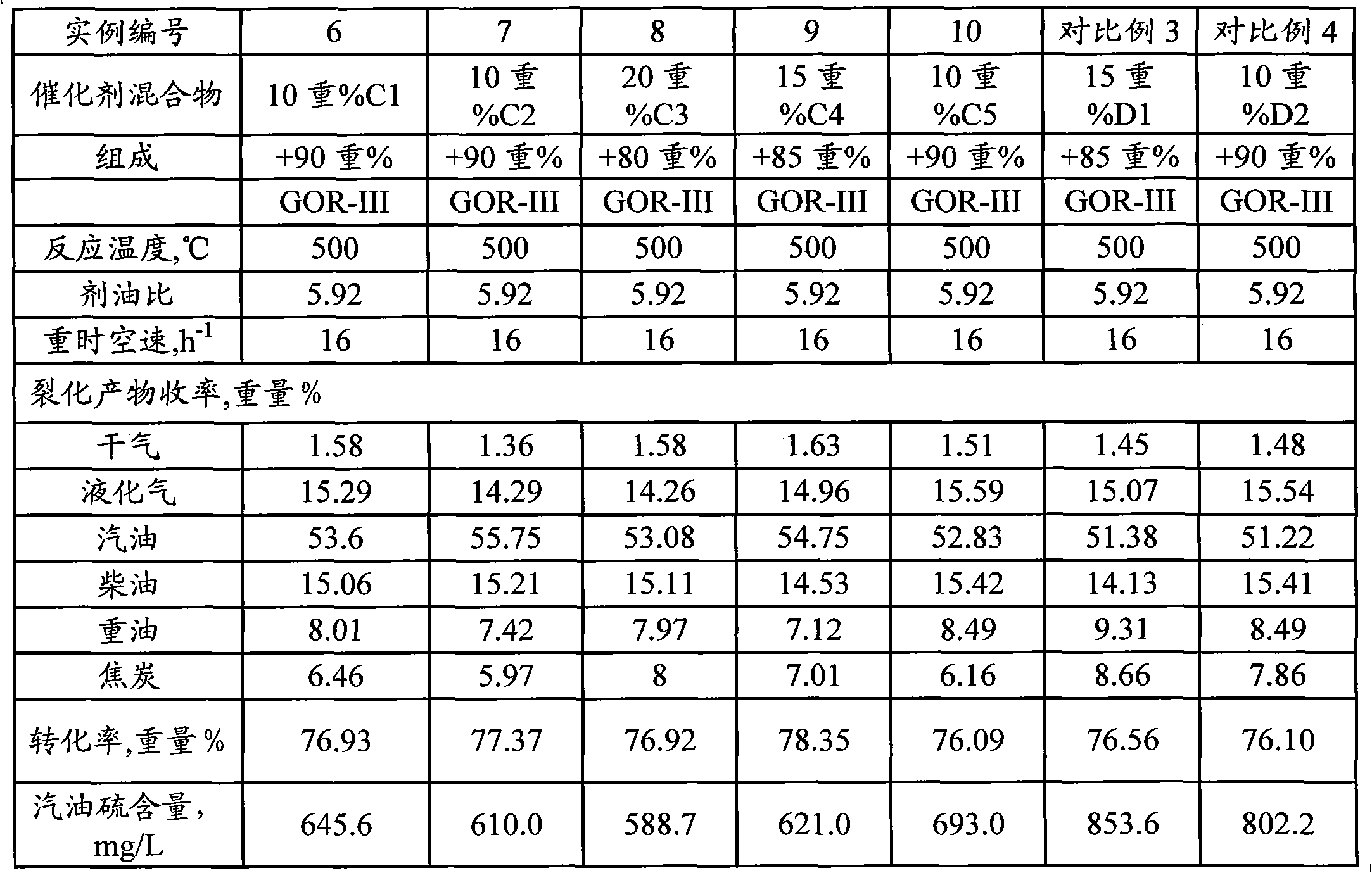

[0026] In the method for reducing sulfur of catalytic cracking products provided by the present invention, the amount of the additive provided by the present invention in the catalyst...

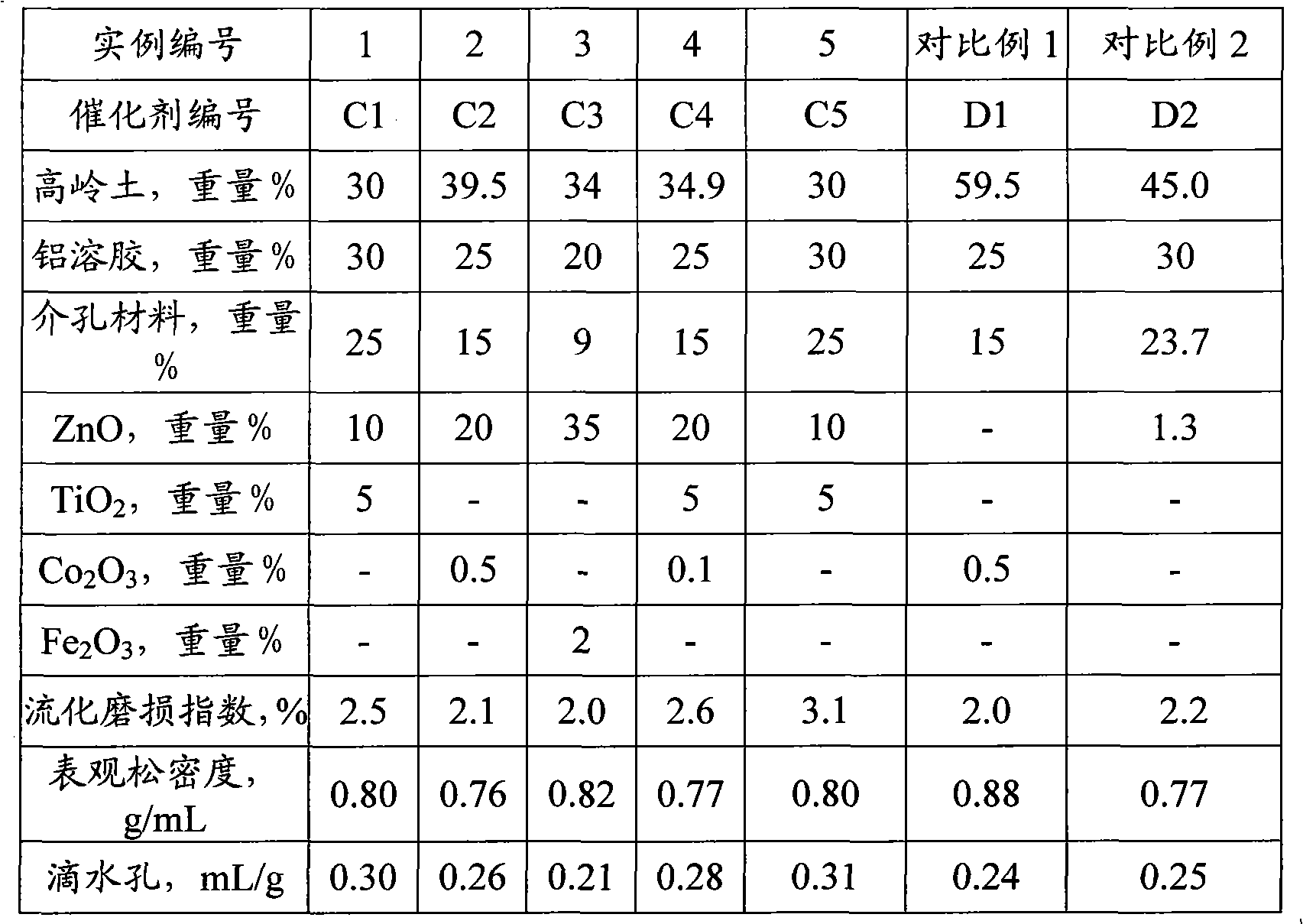

Embodiment 1

[0030] This example illustrates the auxiliary agent provided by the present invention and its preparation method.

[0031] Mix 1.6 kg of mesoporous material (on a dry basis, the same below), deionized water and 840 g of zinc chloride, and beat to obtain a slurry with a solid content of 16% by weight. Add 250 g of titanium dioxide to the slurry and stir for 20 minutes , add 2.0 kg of kaolin, make a slurry, then add 7.1 kg of aluminum sol, stir evenly, then spray dry, and roast at 600 ° C for 3 hours to obtain the auxiliary agent C1 provided by the present invention. The composition and physical and chemical properties of C1 are listed in Table 1.

Embodiment 2

[0033] This example illustrates the auxiliary agent provided by the present invention and its preparation method.

[0034] Mix and beat 1 kg of mesoporous material, deionized water and 1.67 kg of zinc chloride to obtain a slurry with a solid content of 15% by weight, add 90 g of cobalt nitrate to the slurry, continue stirring for 30 minutes, and then add 2.6 kg The kaolin was beaten, and then 6.0 kg of aluminum sol was added, the above slurry was stirred evenly, then spray-dried, and roasted at 500°C for 4 hours to obtain the auxiliary agent C2 provided by the present invention. The composition and physical and chemical properties of C2 are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com