A high-strength and high-conductivity copper-based composite material and its preparation method

A technology of copper-based composite materials and composite materials, which is applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve the problems of material electrical and thermal conductivity decline, material electrical conductivity improvement is small, and material electrical conductivity is affected. Saving resources, short process, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

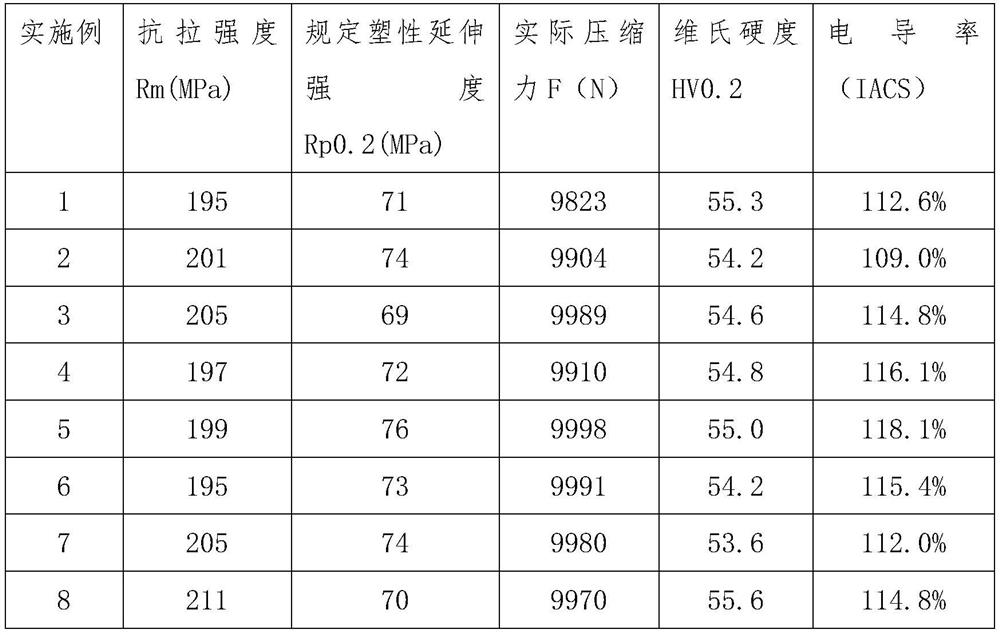

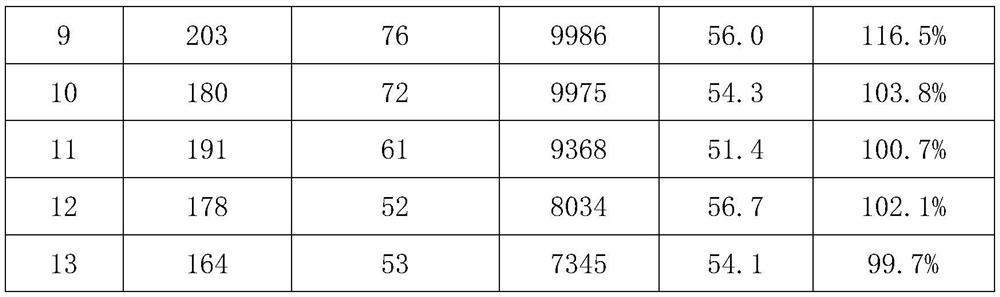

Examples

Embodiment 1

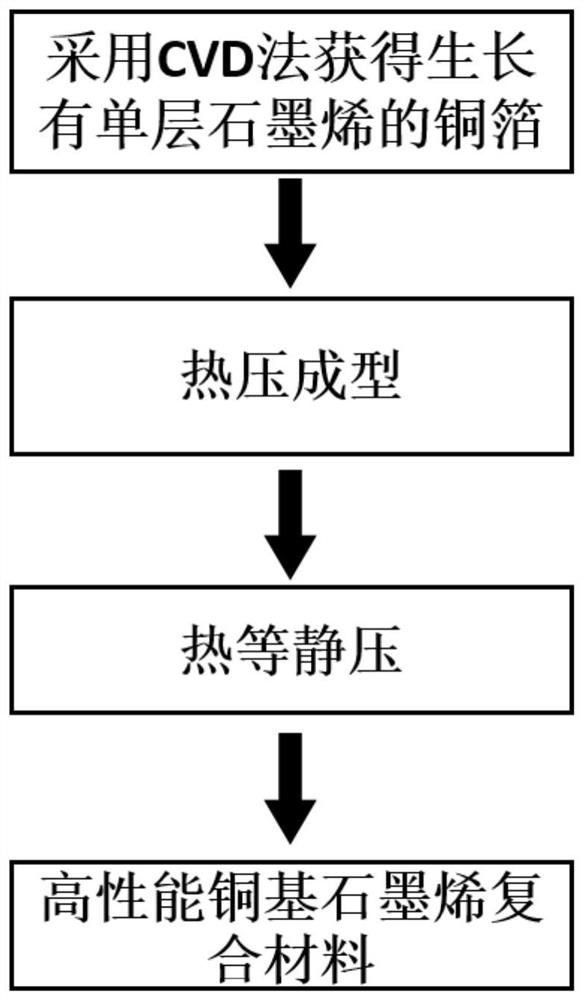

[0029] This embodiment provides a copper-based composite material, the specific preparation method is as follows (flow chart see figure 1 ):

[0030] (1) Use a vacuum hot-press furnace to stack and press 30 pieces of highly oriented metal copper foils with single-layer graphene induced by CVD. When the vacuum degree is lower than 1.0 -1 After Pa, start to heat up to 700°C, at 700°C, pressurize it with a pressure of 20MPa and keep the pressure for 8min, and press it into a composite material to be processed. Wherein, the copper foil deposited with graphene is used as the unit material, and during the lamination, the graphene layer of one unit material is placed in contact with the copper foil of the other unit material.

[0031] (2) Put the composite material to be processed into a ceramic sheath and place it in a hot isostatic high-pressure container hot-pressing sintering furnace. After sealing the pressure container, first raise the temperature in the container to 700°C and...

Embodiment 2

[0034] This embodiment provides a copper-based composite material. The difference between its preparation process and that of Embodiment 1 is that the pressure in step (2) is 100 MPa.

Embodiment 3

[0036] This embodiment provides a copper-based composite material. The difference between its preparation process and that of Embodiment 1 is that the pressure in step (2) is 110 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com