Ultrahigh-strength and ultrathin bottom board for laminated slab and production method thereof

An ultra-high-strength, laminated board technology, applied in floors, building reinforcements, structural elements, etc., can solve the problems of low section stiffness, crack resistance, low impact resistance, affecting product cost, etc., to achieve high crack resistance, The effect of thin thickness, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

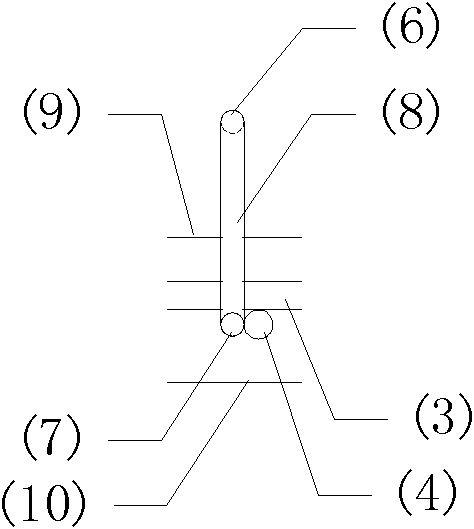

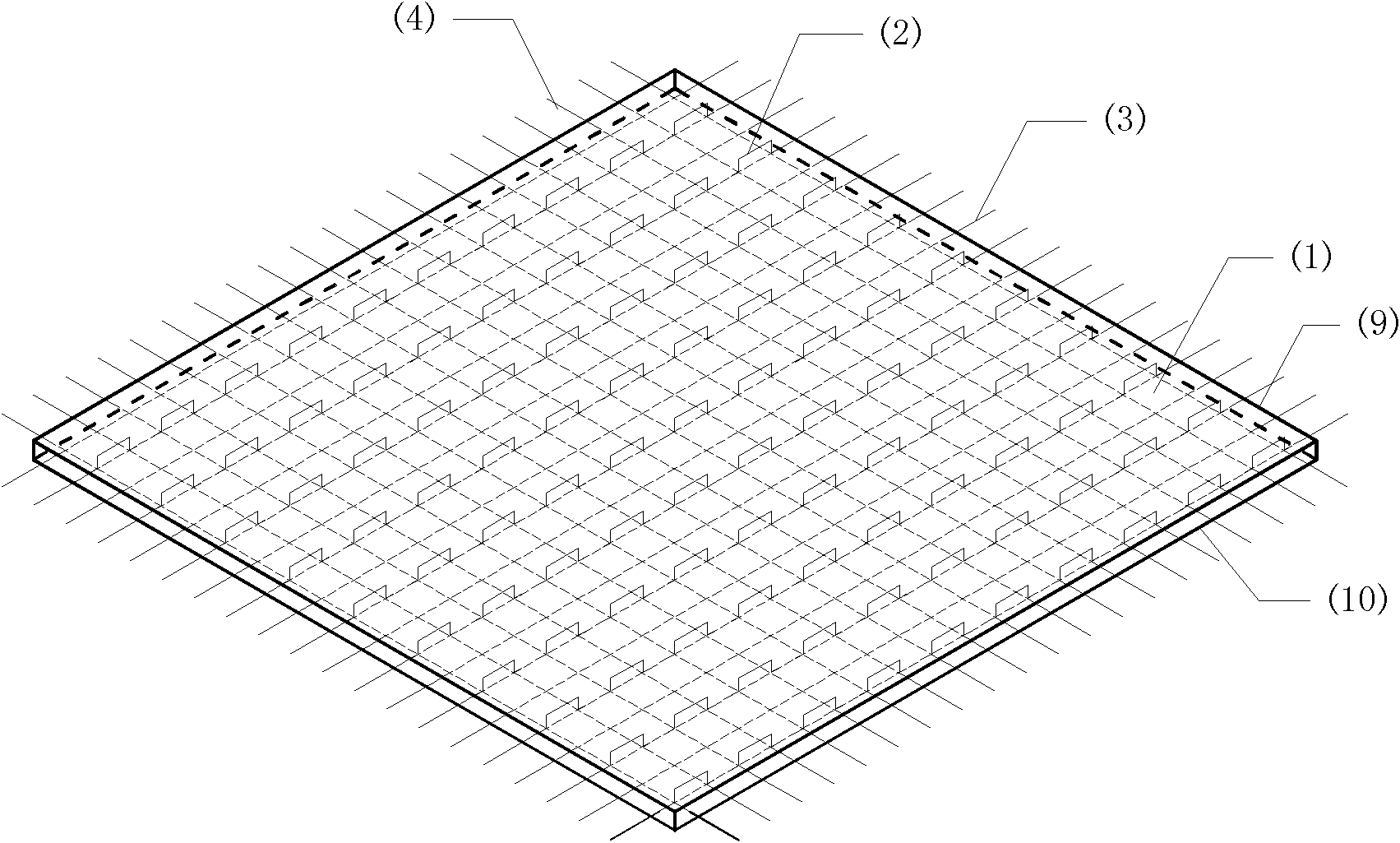

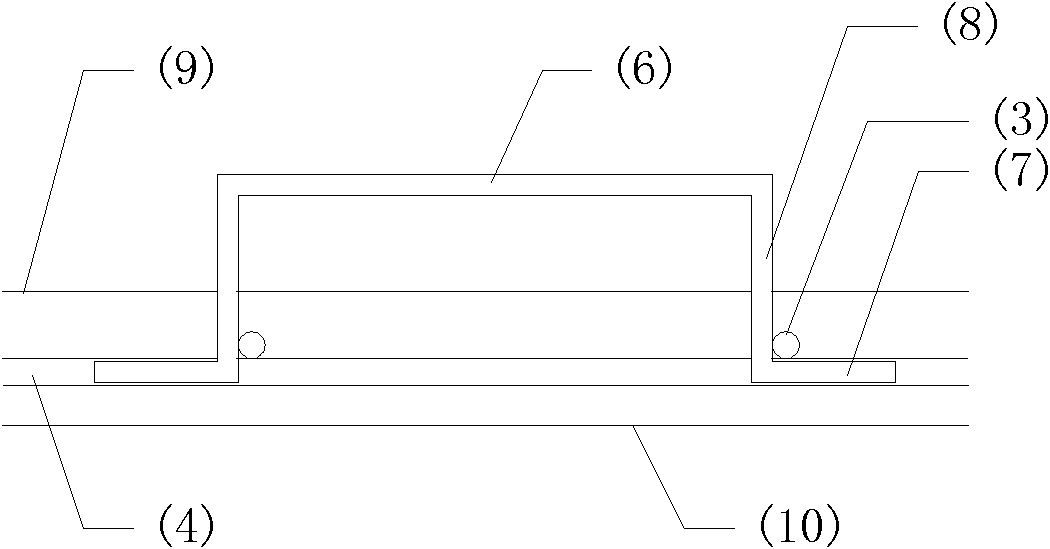

[0027] combine figure 1 , the bottom plate 1 of the ultra-high-strength ultra-thin bottom plate for the laminated board of the present invention includes the special material used for making the bottom plate-fiber-toughened ultra-high-strength high-performance cement-based composite material, the interface shear connector 2 and the vertical and horizontal distribution of the bottom plate. Type steel bar 3,4. The upper surface 9 of the high-performance floor is the contact interface with the post-cast concrete laminated layer, and the lower surface 10 is the clear water roof at the bottom of the slab.

[0028] According to the above characteristic requirements of the special material, the present invention has specially developed a fiber-toughened ultra-high-strength high-performance cement-based composite material. Based on the cement mass ratio, the mix ratio is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com