High-strength, high-toughness and anti-corrosion cobalt-free high-entropy alloy and preparation method thereof

A high-entropy alloy, high-strength and high-toughness technology, which is applied in the field of metal materials and its preparation, can solve the problems of poor plasticity matching of high-entropy alloys, and achieve the effects of excellent plasticity and toughness, uniform structure, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

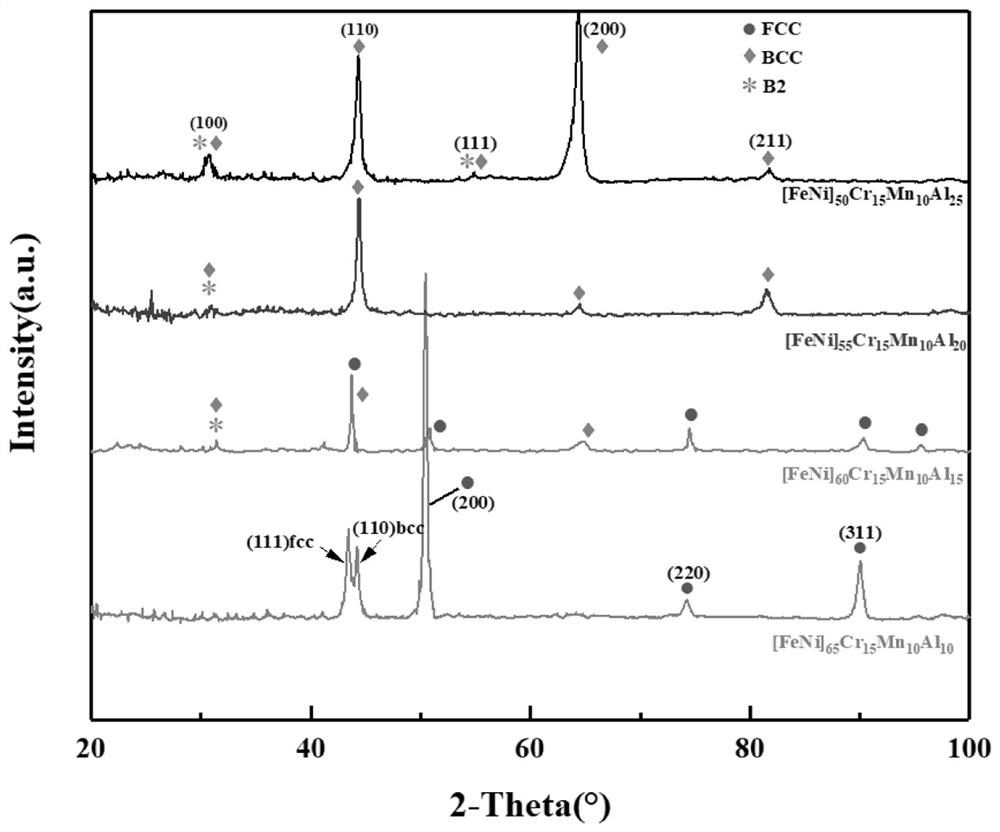

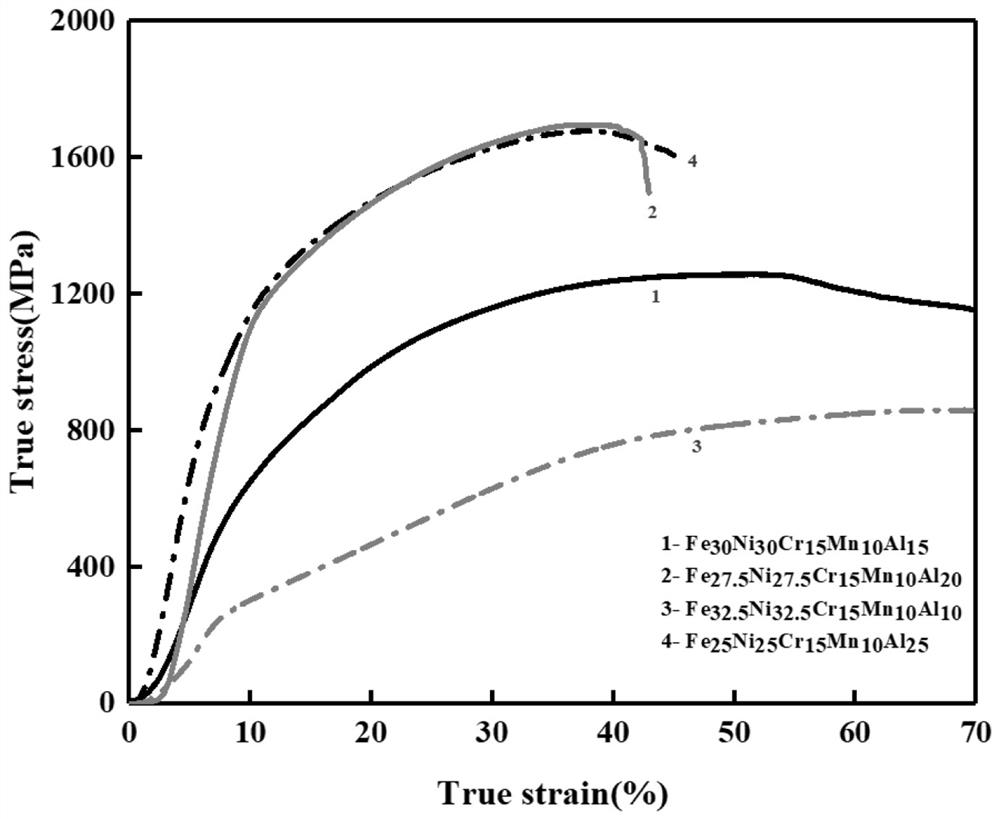

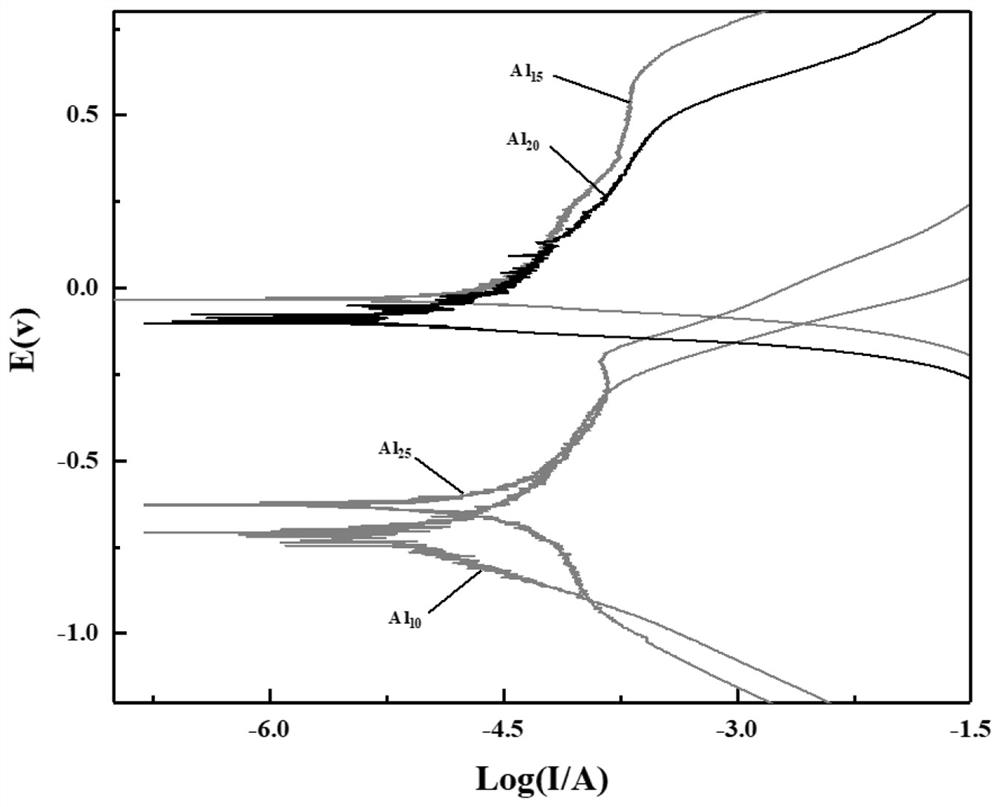

[0036] A high-strength, high-toughness, corrosion-resistant, cobalt-free high-entropy alloy Fe 30 Ni 30 Cr 15 mn 10 Al 15

[0037] Step 1. Metal particles of five elements including Fe, Ni, Cr, Mn and Al are selected as raw materials, and the purity of all metal raw materials is greater than 99.9wt.%.

[0038] Step 2, the molar ratio of Fe: Ni: Cr: Mn: Al of the alloy is 30%: 30%: 15%: 10%: 15%, according to the naming characteristics of high-entropy alloys, the atomic molar ratio of each element The percentages converted into the percentages of the mass of each element in the total mass of the alloy are wt(Fe)=32.40%, wt(Ni)=34.05%, wt(Cr)=15.08%, wt(Mn)=10.63%, wt(Al) =7.84%, and the ingredients of each element are carried out based on the total mass of the prepared alloy.

[0039] Step 3, using a combination of mechanical and chemical methods to remove the surface oxide scales of the raw material metals Fe, Ni, Cr, Mn, Al, and cleaning, drying for later use, that is, ...

Embodiment 2

[0046] A high-strength, high-toughness, corrosion-resistant, cobalt-free high-entropy alloy Fe 27.5 Ni 27.5 Cr 15 mn 10 Al 20

[0047] Step 1. Metal particles of five elements including Fe, Ni, Cr, Mn and Al are selected as raw materials, and the purity of all metal raw materials is greater than 99.9wt.%.

[0048] Step 2, the molar ratio of Fe: Ni: Cr: Mn: Al of the alloy is 27.5%: 27.5%: 15%: 10%: 20%, according to the naming characteristics of high-entropy alloys, the atomic moles of each element The percentages converted into the mass of each element in the total mass of the alloy are wt(Fe)=30.60%, wt(Ni)=32.16%, wt(Cr)=15.54%, wt(Mn)=10.95%, wt(Al) =10.75%, and the ingredients of each element are carried out based on the total mass of the prepared alloy.

[0049] Step 3, using a combination of mechanical and chemical methods to remove the surface oxide scales of the raw material metals Fe, Ni, Cr, Mn, Al, and cleaning, drying for later use, that is, using sandpaper ...

Embodiment 3

[0056] A high-strength, high-toughness, corrosion-resistant, cobalt-free high-entropy alloy Fe 32.5 Ni 32.5 Cr 15 mn 10 al 10

[0057] Step 1. Metal particles of five elements including Fe, Ni, Cr, Mn and Al are selected as raw materials, and the purity of all metal raw materials is greater than 99.9wt.%.

[0058] Step 2, the molar ratio of Fe: Ni: Cr: Mn: Al of the alloy is 32.5%: 32.5%: 15%: 10%: 10%, according to the naming characteristics of high-entropy alloys, the atomic moles of each element The percentages converted into the percentages of the mass of each element in the total mass of the alloy are wt(Fe)=34.11%, wt(Ni)=35.84%, wt(Cr)=14.66%, wt(Mn)=10.32%, wt(Al) =5.07%, and the ingredients of each element are carried out based on the total mass of the prepared alloy.

[0059] Step 3, using a combination of mechanical and chemical methods to remove the surface oxide scales of the raw material metals Fe, Ni, Cr, Mn, Al, and cleaning, drying for later use, that is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com