High strength and high toughness epoxy resin composition applicable for hot melt method preparation of carbon fiber reinforced composite prepreg

A reinforced composite material and epoxy resin technology, which is applied in the field of high-strength and high-toughness epoxy resin compositions, can solve the problems of compressive strength, low interlaminar shear strength, low fatigue resistance and impact strength, and high crosslinking density. Good high strength, outstanding impact resistance, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

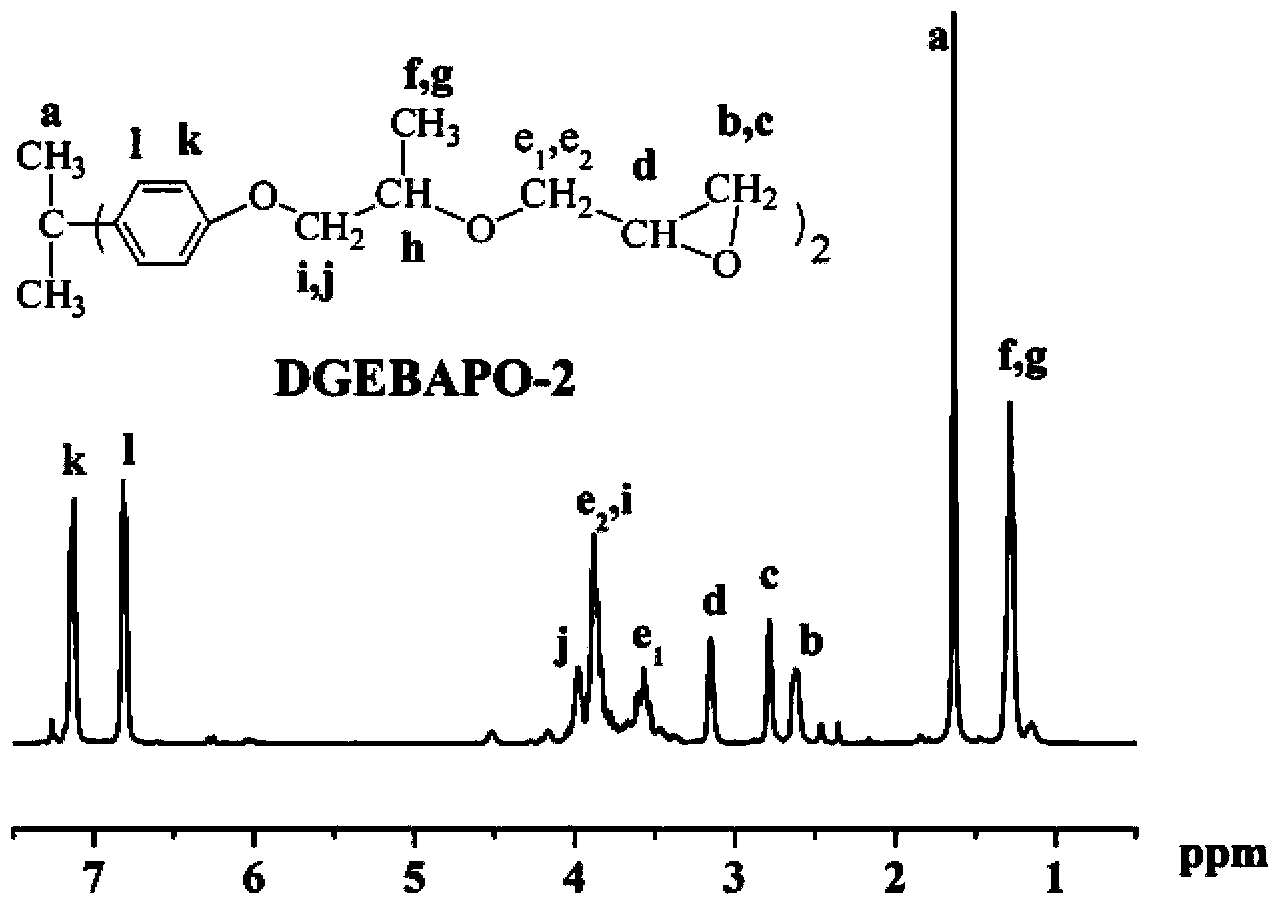

[0041] Add 34.4g of bisphenol A polyether alcohol with the following structural formula, 92.5g of epichlorohydrin and 13g of dimethyl sulfoxide in a 250ml three-necked flask equipped with mechanical stirring, reflux condenser, thermometer and nitrogen gas guide tube. In a nitrogen atmosphere, heat to 60°C to completely dissolve the bisphenol A polyether alcohol in epichlorohydrin, then add 2g of solid sodium hydroxide to start the reaction, then add 2g of solid sodium hydroxide every 0.5 hours for a total of 4 times Add 4g of sodium hydroxide after reacting for 3.5 hours, and then finish the reaction after reacting for 3 hours (reacting in total for 8 hours). After the reaction is over, add deionized water to the reaction system for washing, and wash the water phase to neutrality; then separate the organic phase and distill the volatiles in the organic phase under reduced pressure at 100°C and 3mmHg to obtain bisphenol with the following structure A polyether epoxy resin 41g, ...

Embodiment 2

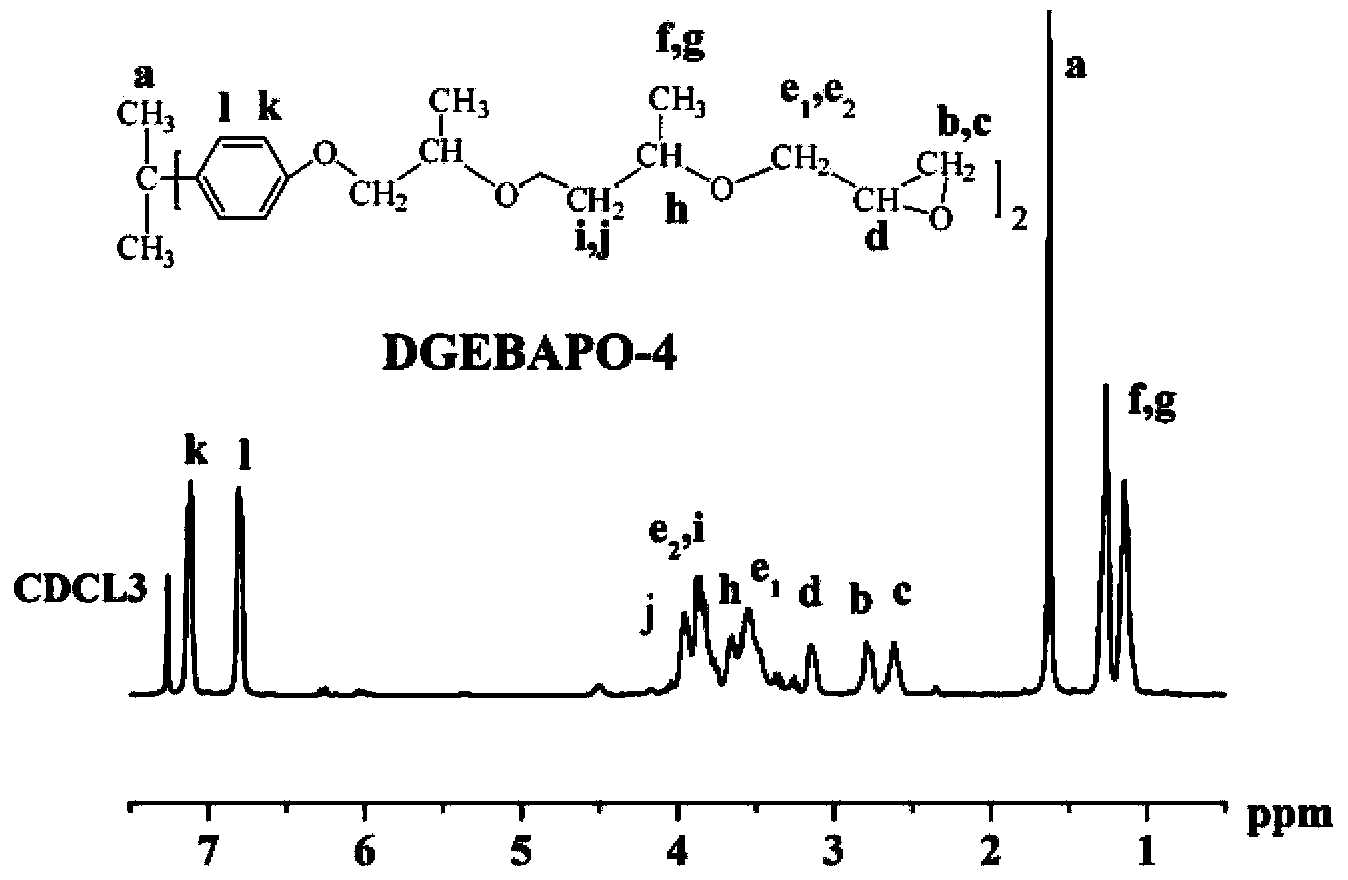

[0044] Add 46g of bisphenol A polyether alcohol with the following structural formula, 111g of epichlorohydrin and 16g of dimethyl sulfoxide into a 250ml three-necked flask equipped with a mechanical stirrer, a reflux condenser, a thermometer, and a nitrogen airway tube. , heated to 70°C to completely dissolve the bisphenol A polyether alcohol in epichlorohydrin, then added 3g of sodium hydroxide solid to start the reaction, then added 3g of sodium hydroxide solid every 0.5 hours, adding 4 times in total, and reacted After 2.5 hours, 4 g of sodium hydroxide was added, and the reaction was completed after 3 hours of reaction (total reaction of 7 hours). After the reaction is over, add deionized water to the reaction system for washing, and wash the water phase to neutrality; then separate the organic phase and distill the volatiles in the organic phase under reduced pressure at 100°C and 3mmHg to obtain bisphenol with the following structure A polyether epoxy resin 50g, product...

Embodiment 3

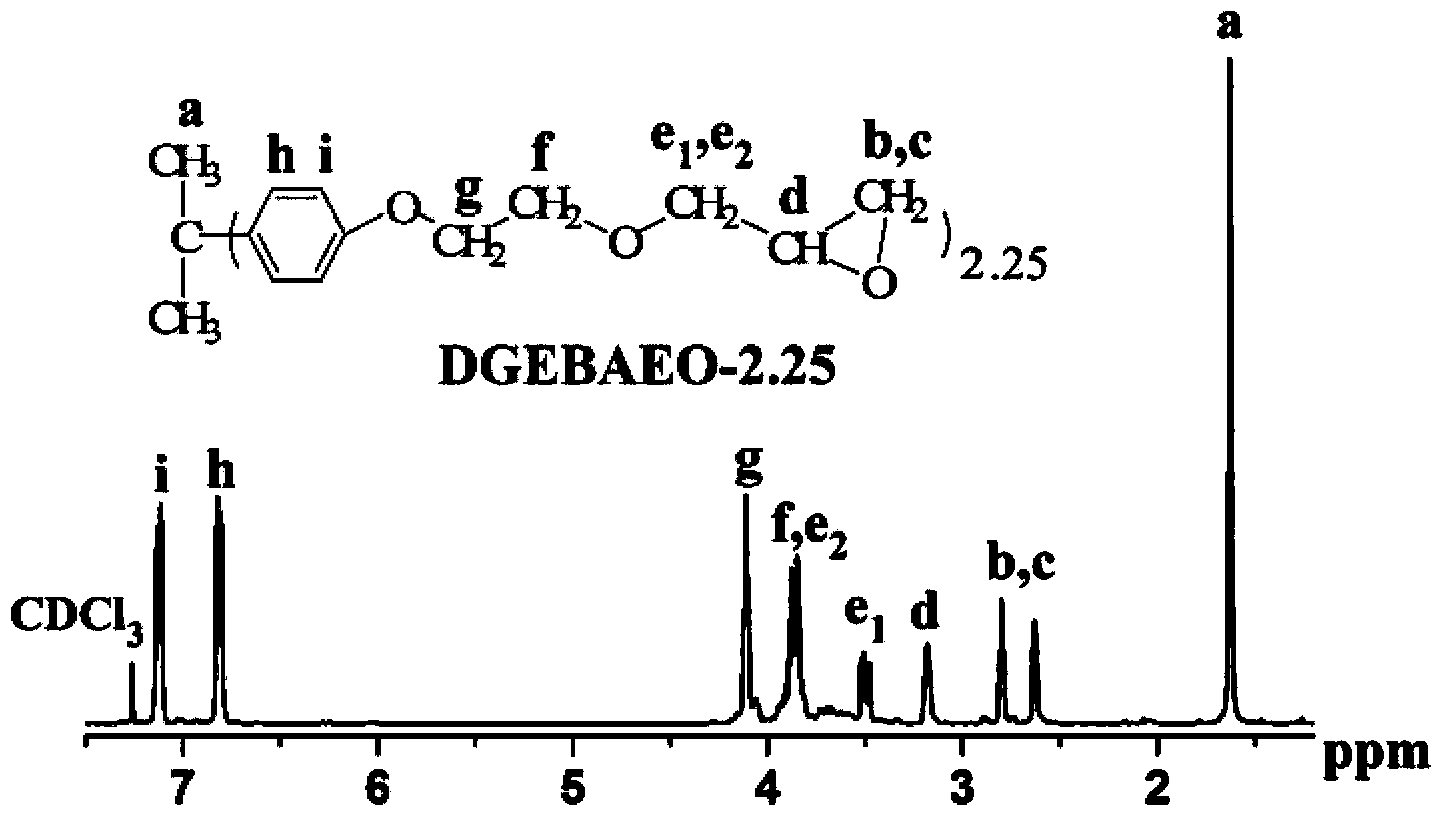

[0047] Add 262g of bisphenol A polyether alcohol with the following structural formula, 740g of epichlorohydrin and 100g of dimethyl sulfoxide into a 2000ml three-necked flask equipped with a mechanical stirrer, a reflux condenser, a thermometer and a nitrogen gas guide tube, in a nitrogen atmosphere , heated to 50°C to dissolve the bisphenol A polyether alcohol in epichlorohydrin completely, then added 16g of sodium hydroxide solid to start the reaction, then added 16g of sodium hydroxide solid every 1 hour, adding 4 times in total, and reacting After 2 hours, 32 g of sodium hydroxide was added, and the reaction was completed after 2 hours of reaction (total reaction of 7 hours). After the reaction is over, add deionized water to the reaction system for washing, and wash the water phase to neutrality; then separate the organic phase and distill the volatiles in the organic phase under reduced pressure at 100°C and 3mmHg to obtain bisphenol with the following structure A polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com