High-strength and high-corrosion-resistance ternary magnesium alloy and preparation method thereof

A magnesium alloy and corrosion-resistant technology, applied in the field of magnesium alloys, can solve the problems of unfavorable service, poor absolute mechanical properties, and poor corrosion resistance of magnesium alloys, and achieve obvious corrosion resistance, good compatibility, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

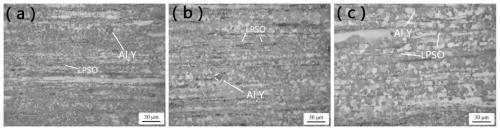

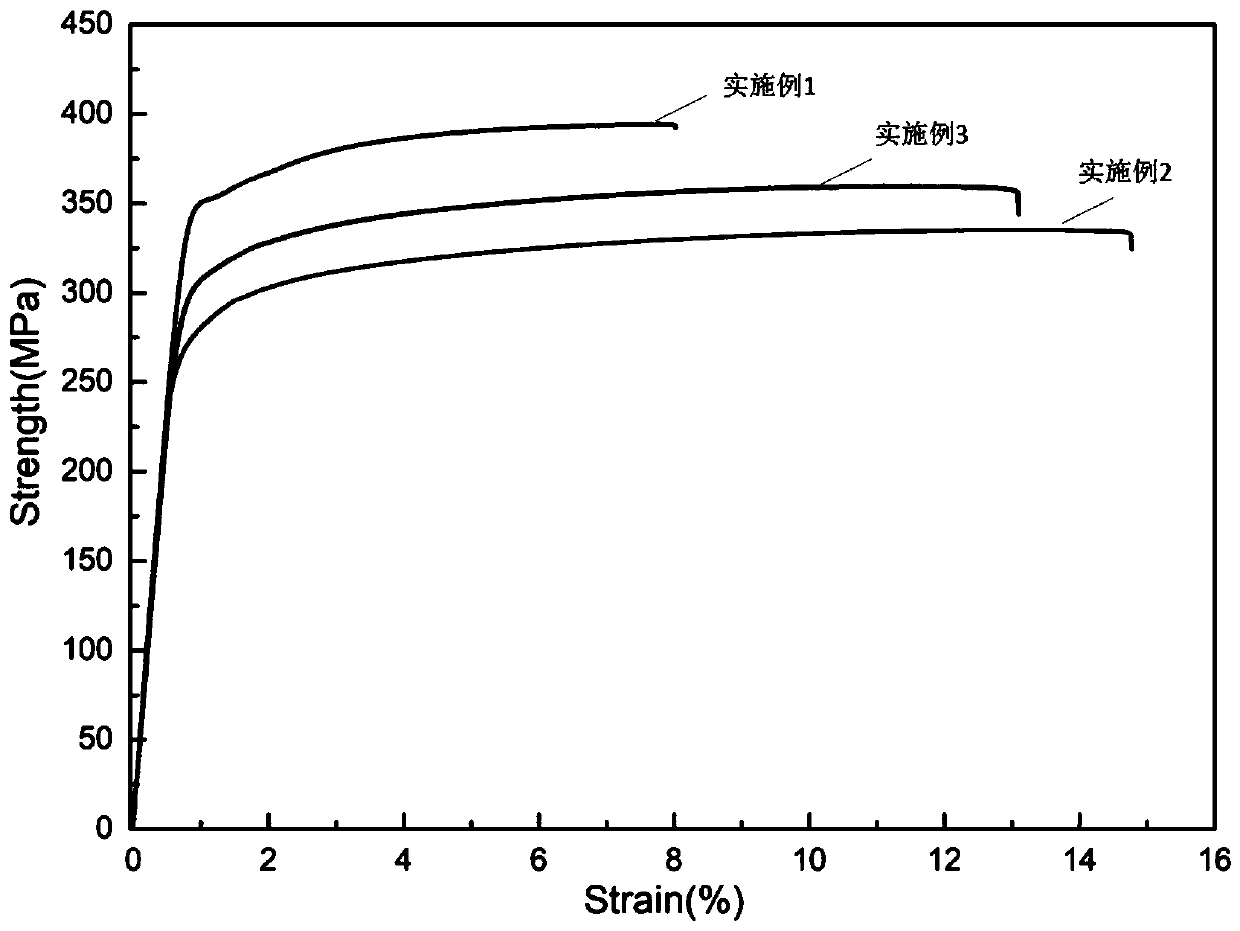

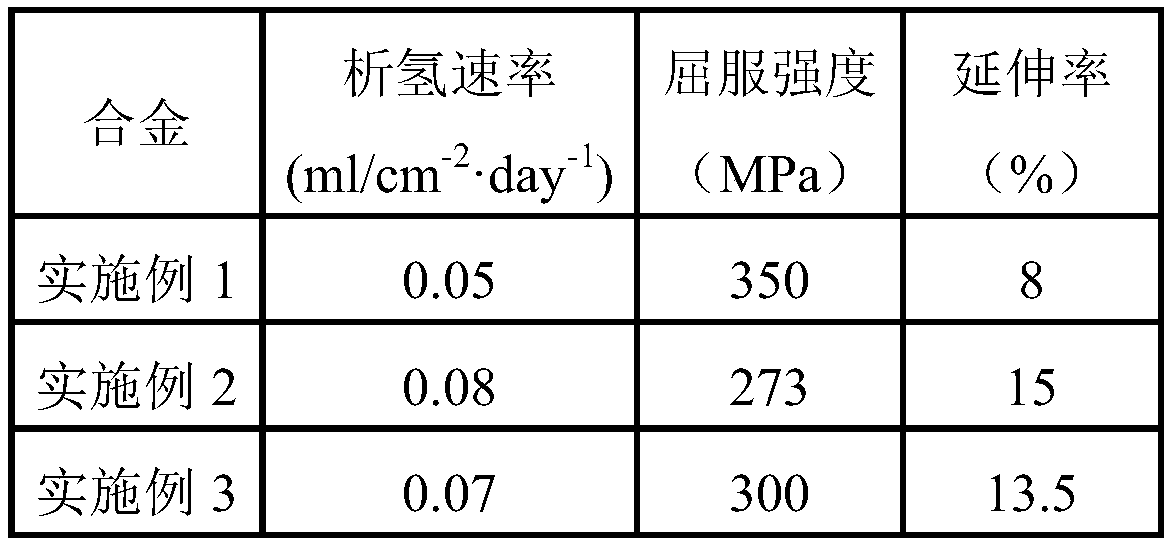

Embodiment 1

[0034] The present embodiment prepares the method for ternary magnesium alloy, in protective atmosphere (protective gas is SF 6 and CO 2 Mixed gas), carry out the following steps:

[0035] (1) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), after melting the magnesium ingot with a purity of not less than 99.9ωt%, add Mg-Y master alloy and aluminum ingot at 660-700°C, and after the Mg-Y master alloy and aluminum ingot are melted, A magnesium alloy melt is obtained.

[0036] (2) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), the magnesium alloy melt was stirred at 730-740°C and then allowed to stand for 20 minutes, then refined at 740-750°C for degassing and slag removal, and then placed at 730-740°C Carry out heat preservation 30min, obtain magnesium alloy liquid;

[0037] (3) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), the magnesium alloy solution is cast to obtain an ingot;

[0...

Embodiment 2

[0041] This embodiment prepares the method for novel corrosion-resistant ternary magnesium alloy, carries out the following steps:

[0042] (1) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), after melting the magnesium ingot with a purity of not less than 99.9ωt%, add Mg-Y master alloy and aluminum ingot at 660-700°C, and after the Mg-Y master alloy and aluminum ingot are melted, A magnesium alloy melt is obtained.

[0043] (2) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), the magnesium alloy melt was stirred at 730-740°C and then allowed to stand for 20 minutes, then refined at 740-750°C for degassing and slag removal, and then placed at 730-740°C Carry out heat preservation 30min, obtain magnesium alloy liquid;

[0044] (3) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), the magnesium alloy solution is cast to obtain an ingot;

[0045] (4) Put the magnesium alloy ingot into the air...

Embodiment 3

[0048] The method for preparing the novel corrosion-resistant ternary magnesium alloy in this embodiment includes:

[0049] (1) In a protective atmosphere (the protective gas is SF 6 and CO 2 mixed gas), after melting the magnesium ingot with a purity of not less than 99.9wt%, add Mg-Y master alloy and aluminum ingot at 660-700°C, and after the Mg-Y master alloy and aluminum ingot are melted, A magnesium alloy melt is obtained.

[0050] (2) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), the magnesium alloy melt was stirred at 730-740°C and then allowed to stand for 20 minutes, then refined at 720-730°C for degassing and slag removal, and then placed at 720-730°C Carry out heat preservation 30min, obtain magnesium alloy liquid;

[0051] (3) In a protective atmosphere (the protective gas is SF 6 and CO 2 Mixed gas), the magnesium alloy solution is cast to obtain an ingot;

[0052] (4) Put the magnesium alloy ingot into the air furnace for sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com