High-strength high-performance concrete

A high-performance concrete and high-strength technology, applied in the field of high-strength concrete materials for building pouring, can solve problems that affect the durability and stability of building structures, do not meet the requirements for energy conservation and emission reduction, and affect the thermal insulation of building structures. Fluidity is not easy to produce cracks, good durability, and good construction fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

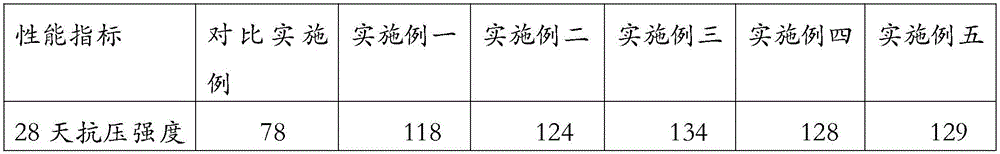

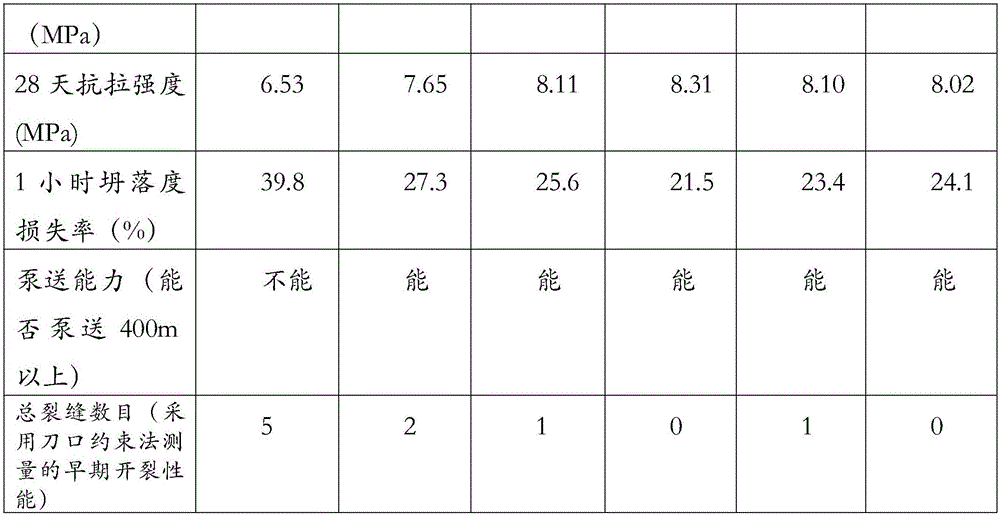

Examples

Embodiment 1

[0022] 210kg of cement, 20kg of fly ash, 520kg of sand, 850kg of crushed stone, 12kg of hemihydrate gypsum, 40kg of kaolin, 20kg of serpentine powder, 20kg of zirconium silicate, 25kg of polycarboxylate superplasticizer, 110kg of water, and silica fume 15kg and 20kg of carbide slag were mixed to prepare concrete.

Embodiment 2

[0024] 245kg of cement, 29kg of fly ash, 740kg of sand, 1080kg of crushed stone, 28kg of hemihydrate gypsum, 53kg of kaolin, 38kg of serpentine powder, 40kg of zirconium silicate, 28kg of polycarboxylate superplasticizer, 145kg of water, and silica fume 38kg and 39kg of calcium carbide slag were mixed to prepare concrete.

Embodiment 3

[0026] 220kg of cement, 25kg of fly ash, 625kg of sand, 950kg of crushed stone, 23kg of hemihydrate gypsum, 47kg of kaolin, 33kg of serpentine powder, 28kg of zirconium silicate, 27kg of polycarboxylate superplasticizer, 125kg of water, and silica fume 27kg and 33kg of calcium carbide slag were mixed to prepare concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com