A kind of waterborne hyperbranched polyester resin and its preparation method and application

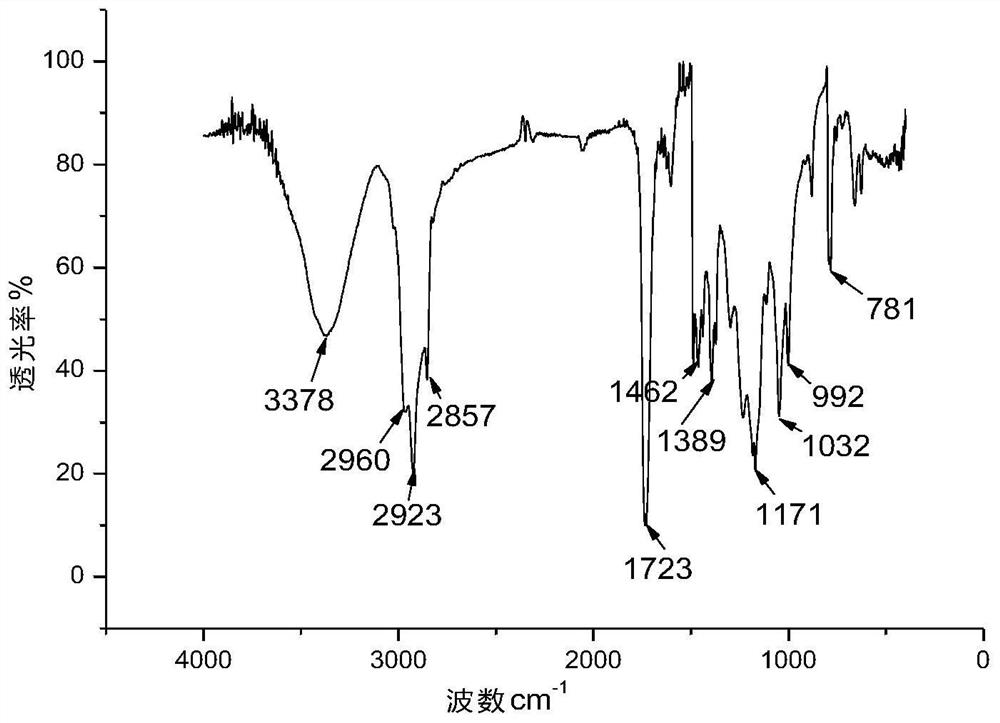

A technology of hyperbranched polyester and hydroxy polyester resin, applied in the direction of coating, can solve the problems of poor mechanical properties such as drying performance and hardness of the coating film, easy hydrolysis of water-based polyester, poor stability and other problems, and achieve the construction viscosity. Low, low molecular weight, high solids effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

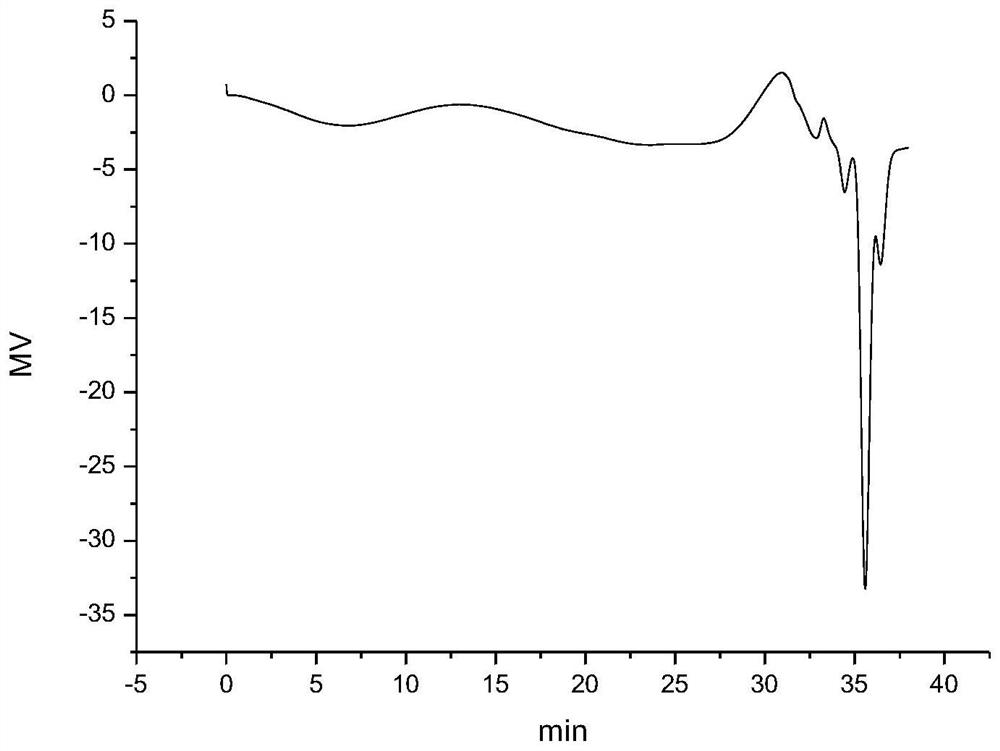

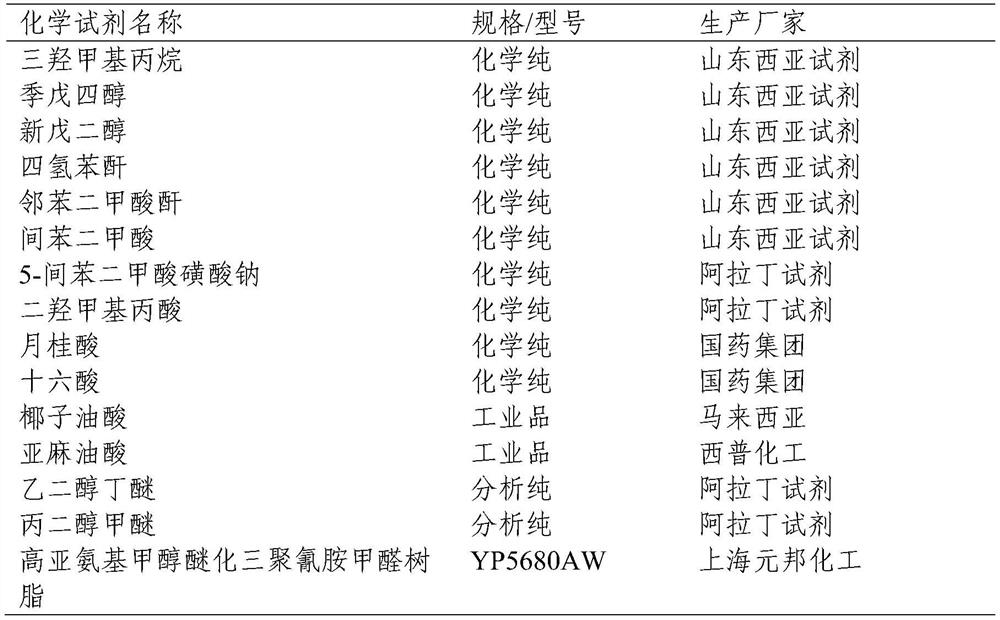

[0039](1) Synthesis of the first generation of hyperbranched hydroxyl polyester resin: 10.56g of trimethylolpropane (0.078mol), 95g of dimethylol propionic acid (0.7089mol), and 3.0g of esterification catalyst were added to a four-necked flask , heat up to 145-150°C, and react for 180-210min. Determination of acid value, calculation of reaction degree;

[0040] (2) hyperbranched polyester resin grafted organic sulfonate: when (1) the degree of reaction reaches more than 90%, add 186.43g of trimethylolpropane and 35g of sodium sulfonate isophthalate, and continue to heat up to 180°C React for 1 hour, then raise the temperature to 200°C at a heating rate of 5°C / 10min, keep warm until the solution in the four-necked flask is transparent;

[0041] (3) Synthesis of modified water-based hyperbranched hydroxyl polyester resin: Add 192g of lauric acid and 200g of tetrahydrophthalic anhydride to the above solution (2), gradually raise the temperature to 210°C at a heating rate of 5°C / ...

Embodiment 2

[0043] (1) Synthesis of the first generation of hyperbranched hydroxyl polyester resin: 9.818g of trimethylolpropane (0.073mol), 88g of dimethylolpropionic acid (0.657mol), and 3.0g of esterification catalyst were added to a four-necked flask , heat up to 145-150°C, and react for 180-210min. Determination of acid value, calculation of reaction degree;

[0044] (2) hyperbranched polyester resin grafted organic sulfonate: when (1) reaction degree reaches more than 90%, add trimethylolpropane 117.19g, neopentyl glycol 91g, sodium sulfonate isophthalate 39g , continue to heat up to 180°C for 1 hour, then raise the temperature to 200°C at a heating rate of 5°C / 10min, keep warm until the solution in the four-necked flask is transparent;

[0045] (3) Synthesis of modified water-based hyperbranched hydroxyl polyester resin polyester: add coconut oil 156g, phthalic anhydride 165g, and isophthalic acid 52g in the above (2) solution, and gradually heat up at 5°C / 10min Raise the tempera...

Embodiment 3

[0047] (1) Synthesis of the first generation of hyperbranched hydroxy polyester resin: 8.41g of pentaerythritol (0.061mol), 98g of dimethylol propionic acid (0.7313mol), and 3.0g of esterification catalyst were added to a four-necked flask, and the temperature was raised to 145 -150°C, react for 180-210min. Determination of acid value, calculation of reaction degree;

[0048] (2) hyperbranched polyester resin graft organic sulfonate: when (1) degree of reaction reaches more than 90%, add pentaerythritol 99.59g, neopentyl glycol 58g, sodium sulfonate isophthalate 36g, continue to heat up to React at 180°C for 1 hour, then raise the temperature to 200°C at a heating rate of 5°C / 10min, keep warm until the solution in the four-necked flask is transparent;

[0049] (3) Polyester synthesis of modified water-based hyperbranched hydroxyl polyester resin: add palmitic acid 184g, tetrahydrophthalic anhydride 170g, isophthalic acid 55g in the above (2) solution, and gradually heat up at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com