A kind of rubber cold mix epoxy asphalt mixture and preparation method for crack repair

A technology for cold-mix epoxy asphalt and crack repair, which is applied in the field of rubber cold-mix epoxy asphalt mixture and preparation, and the field of road crack cold repair material, which can solve the problems that restrict the promotion and application of emulsified asphalt, the physical damage of operators, and asphalt smoke. Air pollution and other problems, to achieve the effect of improving construction fluidity, low construction cost, and excellent high-strength bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

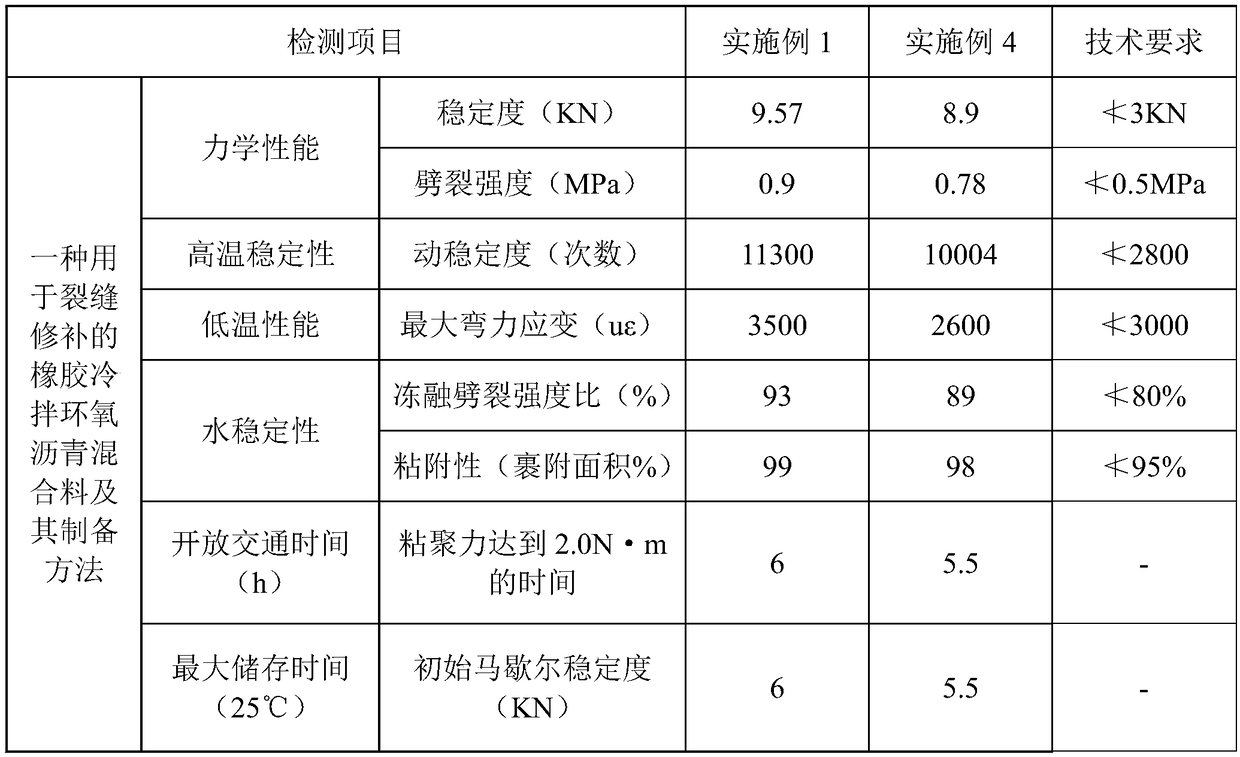

Examples

Embodiment 1

[0027] Embodiment 1: the preparation of rubber cold mix epoxy asphalt mixture

[0028] Raw material weight ratio:

[0029] 0-3mm particle size of basalt crushed stone mineral material, 44 parts; 3-5mm particle size of basalt rock crushed mineral material, 12.5 parts; 5-10mm particle size of basalt rock crushed mineral material, 31 parts; Corresponding to mineral materials: rubber particles, 10 parts; water-based epoxy resin, 8 parts; emulsified asphalt, 3 parts; mineral powder, 0.175 parts; accelerator, 0.75 parts; defoamer, 0.03 parts; inorganic additives, 0.175 parts; The water-based epoxy resin includes a component A water-based epoxy emulsion and a B-component curing agent, and the weight ratio of the A-component water-based epoxy emulsion to the B-component curing agent is 1.75:1.

[0030] Wherein, the emulsified asphalt is a fast-cracking cationic emulsified asphalt with a solid content of 52% and an Engua viscosity of 28; the rubber particles are a mixture of rubber pa...

Embodiment 2

[0035] Embodiment 2: the preparation of rubber cold mix epoxy asphalt mixture

[0036] Raw material weight ratio:

[0037] 0-3mm particle size of basalt crushed stone mineral material, 40 parts; 3-5mm particle size of basalt rock crushed mineral material, 10 parts; 5-10mm particle size of basalt rock crushed mineral material, 25 parts; Corresponding to mineral materials: rubber particles, 9 parts; water-based epoxy resin, 7 parts; emulsified asphalt, 2 parts; mineral powder, 0.1 part; accelerator, 0.5 part; defoamer, 0.01 part; inorganic additive, 0.1 part; The water-based epoxy resin includes a component A water-based epoxy emulsion and a B-component curing agent, and the weight ratio of the A-component water-based epoxy emulsion to the B-component curing agent is 1:1.

[0038] Wherein, the emulsified asphalt is a fast-cracking cationic emulsified asphalt with a solid content of 54% and an Engua viscosity of 26; the rubber particles are a mixture of rubber particles with a p...

Embodiment 3

[0043] Embodiment 3: the preparation of rubber cold mix epoxy asphalt mixture

[0044] Raw material weight ratio:

[0045]0-3mm particle size of basalt crushed stone mineral material, 48 parts; 3-5mm particle size of basalt rock crushed mineral material, 15 parts; 5-10mm particle size of basalt rock crushed mineral material, 37 parts; Corresponding to stone ore materials: rubber particles, 11 parts; water-based epoxy resin, 9 parts; emulsified asphalt, 4 parts; mineral powder, 0.25 parts; accelerator, 1 part; defoamer, 0.05 parts; inorganic additives, 0.25 parts; The water-based epoxy resin includes a component A water-based epoxy emulsion and a B-component curing agent, and the weight ratio of the A-component water-based epoxy emulsion to the B-component curing agent is 2.5:1.

[0046] Wherein, the emulsified asphalt is a fast-cracking cationic emulsified asphalt with a solid content of 50% and an Engua viscosity of 30; the rubber particles are a mixture of rubber particles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com