PC/ABS based low-shrinkage high strength and high gloss engineered polypropylene material and preparation method thereof

A polypropylene material, low shrinkage and high technology, applied in the field of low shrinkage, high strength and high gloss engineering polypropylene material and its preparation, can solve the problems of poor dimensional stability, low strength, large shrinkage of high gloss PP, etc., to achieve reduction Specular reflection, low cost, and compatibility-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a low-shrinkage high-strength high-gloss engineering polypropylene material based on PC / ABS, including 65 parts by weight of high-fluidity polypropylene, 10 parts by weight of grafted PP, 5 parts by weight of POE, 5 parts by weight of Parts of PA66 fiber, 15 parts of 5um glass fiber, 1.0 parts by weight of anti-glass fiber exposure agent TAF, 0.3 parts by weight of antioxidant.

[0027] Wherein, the grafted PP is a grafted PP with a grafting rate of 8%. The glass fiber is an ultrafine short glass fiber with a length of 1mm and a diameter of 5um. The organic short fiber is nylon 66 reinforced industrial fiber, and the POE is high fluidity ethylene-butylene elastomer with a fluidity of 10 (190°C*2.16KG). The polypropylene mentioned above is a high-fluidity PP with a fluidity of 45 (230°C*2.16KG).

[0028] The present invention also provides the above-mentioned method for preparing a low-shrinkage, high-strength, high-gloss engineering polypropyl...

Embodiment 2

[0037] The main difference between this example and Example 1 is that the selected formula includes 50 parts by weight of high-fluidity polypropylene, 10 parts by weight of grafted PP, 5 parts by weight of POE, 5 parts by weight of PA66 fiber, 30 parts by weight 5um glass fibers, 1.0 parts by weight of anti-glass fiber exposure agent TAF, and 0.3 parts by weight of antioxidant.

Embodiment 3

[0039] The main difference between this example and Example 1 is that the selected formula includes 52 parts by weight of high-fluidity polypropylene, 8 parts by weight of grafted PP, 10 parts by weight of POE, 10 parts by weight of PA66 fiber, 20 parts by weight 5um glass fiber, 1.0 part by weight of anti-glass fiber exposure agent TAF, 0.3 part by weight of antioxidant, 0.3 part by weight of light stabilizer, and 0.2 part by weight of phthalocyanine red.

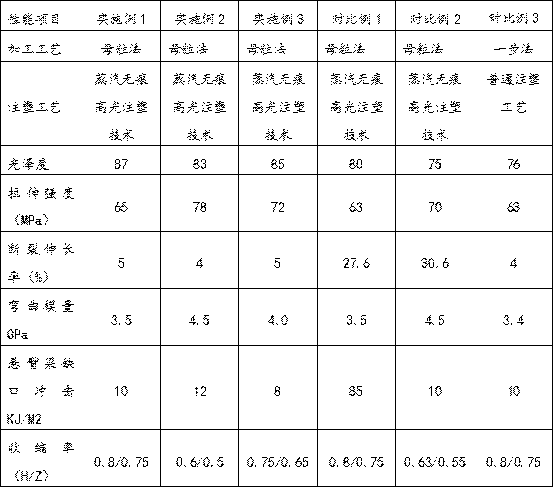

[0040] A group of comparative test examples are listed below to illustrate the beneficial effects of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com