A kind of steel with low yield strength ratio ultra-high strength and high toughness pressure-resistant shell and its preparation method

A technology of pressure-resistant shell and low yield ratio, which is applied in the field of ultra-high-strength and high-toughness steel with low yield ratio and ultra-high-strength high-toughness steel for pressure-resistant shells with low yield ratio, which can solve the problem of high yield ratio of samples. problems, to achieve the effects of excellent low temperature impact toughness, excellent plasticity, and excellent weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A low yield ratio (≤0.9) high-strength and high-toughness pressure-resistant casing steel of the present invention is smelted molten steel according to the set composition and cast into a slab, and the composition is by weight percentage: 0.085%C, 0.25%Si, 0.75% %Mn, 0.50% Mo, 0.6% Cr, 7.20% Ni, 0.12% V, and the balance is Fe and unavoidable impurities.

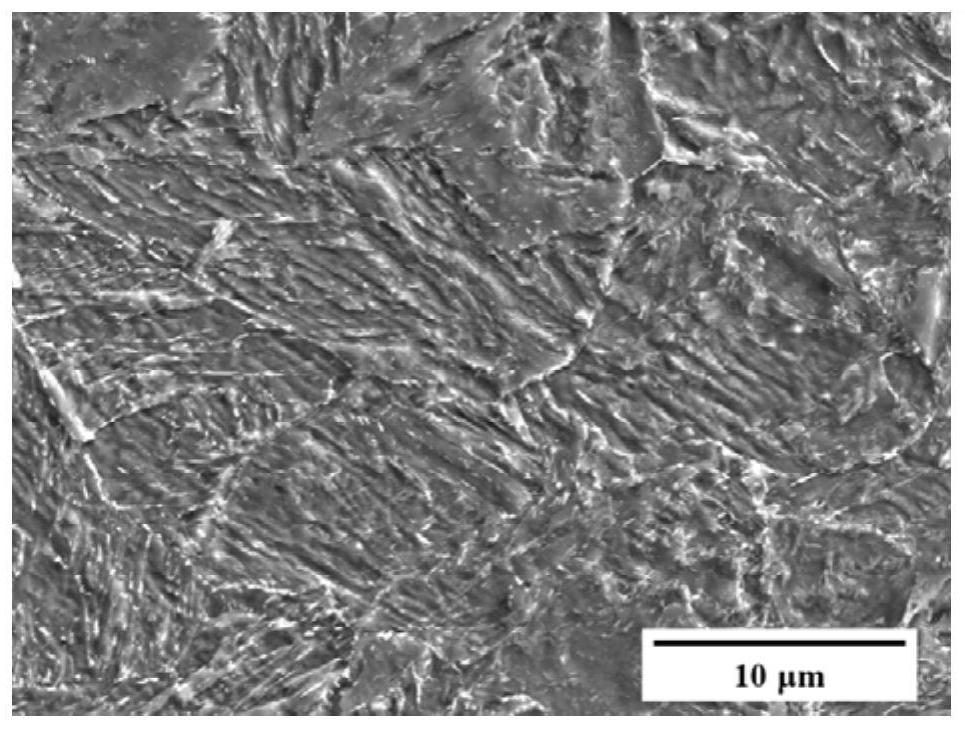

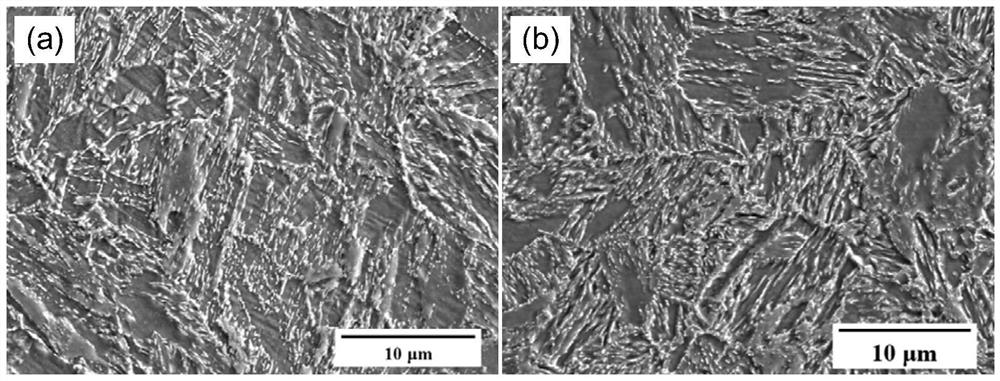

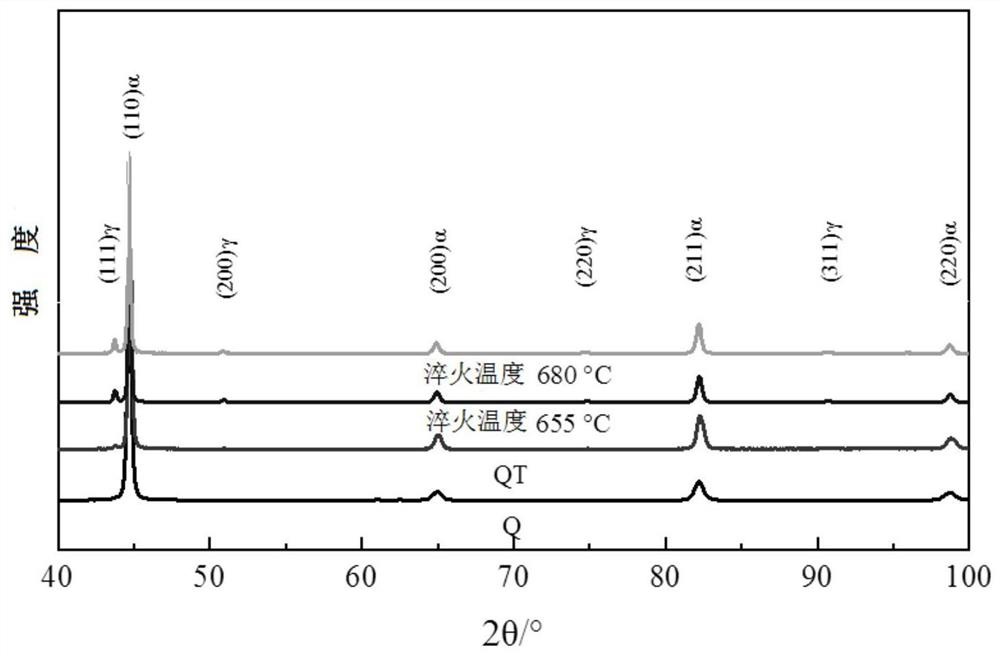

[0035]Heat the slab to 1200°C, keep it warm for 3 hours, and then carry out two-stage hot rolling; the rolling temperature of the first stage is 1150-1000°C, the reduction rate is 50%, the rolling temperature of the second stage is 920-750°C, and the reduction rate is 50% %, and finally the steel plate is hot-rolled to 12.5 mm; the hot-rolled high-temperature steel plate is air-cooled to room temperature. The hot-rolled steel plate samples were heated to 800°C and held for 30 minutes, water quenched to room temperature; then heated to 655°C again, held for 30 minutes, water quenched to room temperature; finally tempere...

Embodiment 2

[0038] A low yield ratio (≤0.9) high-strength and high-toughness pressure-resistant casing steel of the present invention is smelted molten steel according to the set composition and cast into a slab, and the composition is by weight percentage: 0.085%C, 0.25%Si, 0.75% %Mn, 0.50% Mo, 0.6% Cr, 7.20% Ni, 0.12% V, and the balance is Fe and unavoidable impurities.

[0039] Heat the slab to 1200°C, keep it warm for 3 hours, and then carry out two-stage hot rolling; the rolling temperature of the first stage is 1150-1000°C, the reduction rate is 50%, the rolling temperature of the second stage is 920-750°C, and the reduction rate is 50% %, and finally the steel plate is hot-rolled to 12.5 mm; the hot-rolled high-temperature steel plate is air-cooled to room temperature. The hot-rolled steel plate samples were heated to 800°C and held for 30 minutes, water quenched to room temperature; then heated to 680°C again, held for 30 minutes, water quenched to room temperature; finally temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com