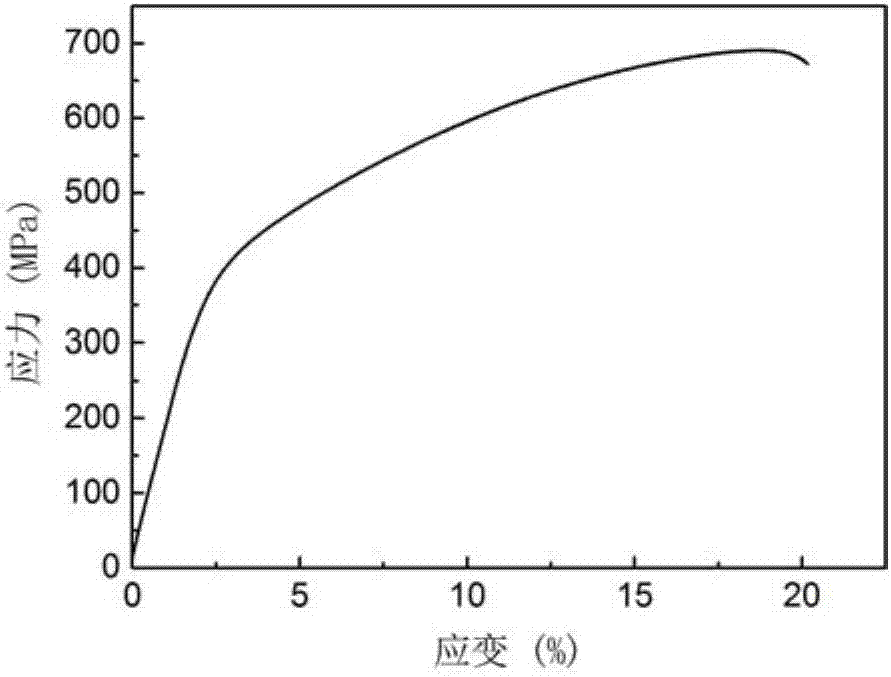

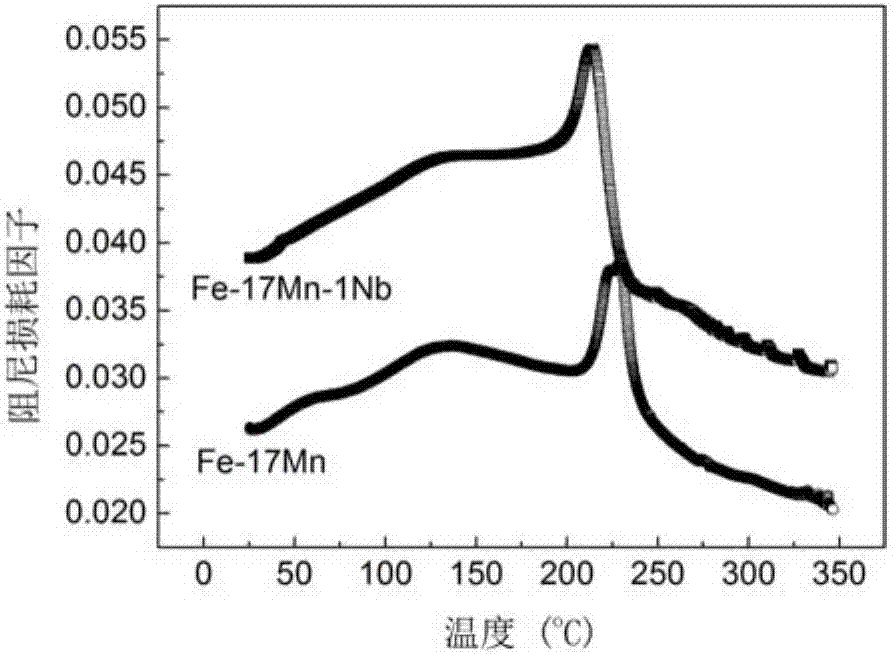

Nb-containing iron-manganese-based damping alloy and preparation method thereof

A damping alloy, iron-manganese-based technology, used in manufacturing tools, heat treatment equipment, furnace types, etc., can solve problems such as undiscovered, and achieve the effects of improving damping performance, high strength, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method and specific steps of the Nb-containing iron-manganese-based high-strength and high-damping alloy of the present invention are as follows:

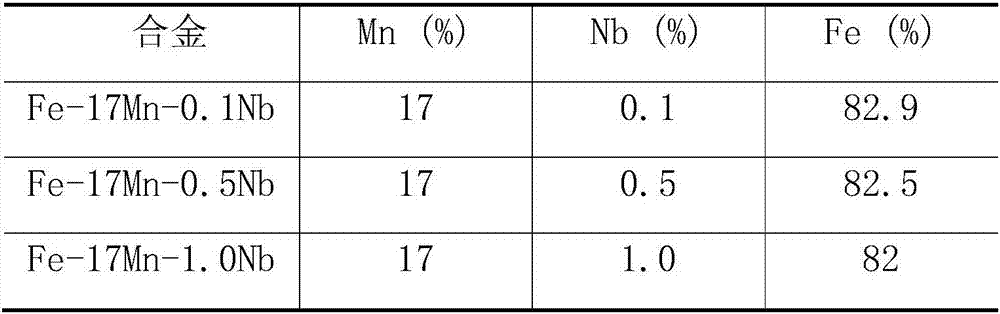

[0030] (1) according to the mass percentage content of each constituent element listed in Table 1, take by weighing Fe with a purity of 99.99%, Mn with a purity of 99.9% and Nb with a purity of 99.95%;

[0031] Table 1 Mass fraction of constituent elements

[0032]

[0033] (2) Put the Fe, Mn and Nb raw materials weighed in the first step into a non-consumable vacuum arc melting furnace, and draw a vacuum so that the vacuum degree of the backside reaches 5×10 -3 Pa, and then filled with high-purity argon to 500Pa, using high-temperature electric arc to melt the raw material into a button-shaped ingot. During melting, the alloy needs to be turned over and smelted five times. Stir to ensure that the sample composition is uniform;

[0034] (3) Put the smelted alloy ingot into a 304 stainless steel tube with...

Embodiment 1

[0039] Example 1: Preparation of Fe-17Mn-0.1Nb alloy.

[0040] (1) According to the mass percentage content of Fe (82.9%), Mn (17%) and Nb (0.1%), it is 99.99% Fe, 99.9% Mn and 99.95% Nb in purity;

[0041] (2) Put the Fe, Mn and Nb raw materials weighed in the first step into a non-consumable vacuum arc melting furnace, and draw a vacuum so that the vacuum degree of the backside reaches 5×10 -3 Pa, and then filled with high-purity argon to 500Pa, using high-temperature electric arc to melt the raw material into a button-shaped ingot. During melting, the alloy needs to be turned over and smelted five times. Stir to ensure that the sample composition is uniform;

[0042] (3) Put the smelted alloy ingot into a 304 stainless steel tube with an outer wire, fill the tube with an oxygen scavenger, screw on the caps at both ends, and fill the gap between the caps with a mass ratio of clay and steel brick powder of 4 : 1 add water and seal the viscous mixture, then put it into a hea...

Embodiment 2

[0046] Example 2: Preparation of Fe-17Mn-0.5Nb alloy.

[0047] (1) According to the mass percentage content of Fe (82.5%), Mn (17%) and Nb (0.5%), it is 99.99% Fe, 99.9% Mn and 99.95% Nb in purity;

[0048] (2) Put the Fe, Mn and Nb raw materials weighed in the first step into a non-consumable vacuum arc melting furnace, and draw a vacuum so that the vacuum degree of the backside reaches 5×10 -3 Pa, and then filled with high-purity argon to 500Pa, using high-temperature electric arc to melt the raw material into a button-shaped ingot. During melting, the alloy needs to be turned over and smelted five times. Stir to ensure that the sample composition is uniform;

[0049] (3) Put the smelted alloy ingot into a 304 stainless steel tube with an outer wire, fill the tube with an oxygen scavenger, screw on the caps at both ends, and fill the gap between the caps with a mass ratio of clay and steel brick powder of 4 : 1 add water and seal the viscous mixture, then put it into a hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com