Method for producing high-strength and high-modulus fluorescent and reflective polyethylene cable

A high-strength and high-modulus polyethylene measurement technology, which is applied in the production of high-strength and high-modulus polyethylene fluorescent reflective cables, can solve problems such as corrosion, cable strength reduction, and fracture, and achieve reduced safety accidents, long service life, and particles small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0015] A production method of high-strength and high-modulus polyethylene fluorescent reflective ropes, weaving 350D ultra-high molecular weight polyethylene filaments into ropes, padding slurry containing fluorescent and reflective powder, drying after winding, and then Baking, so that the fluorescent and reflective powder is evenly distributed on the surface of the rope. The specific operation includes the following steps: fluorescent and reflective paste configuration → ultra-high molecular weight polyethylene filament → braiding rope → padding fluorescent and reflective paste → winding → baking dry→baked; where:

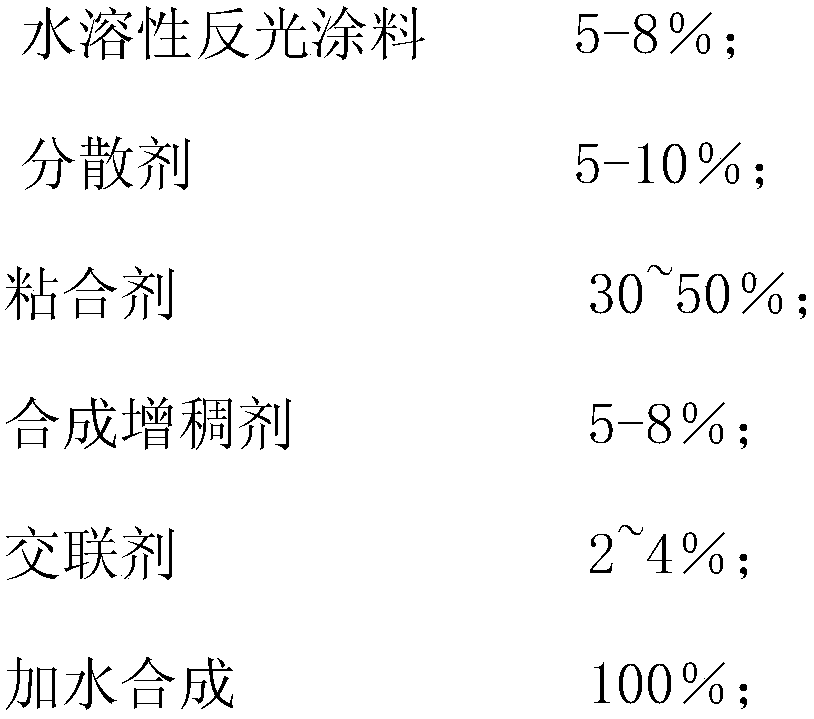

[0016] In the configuration of the fluorescent and reflective paste: the composition of the fluorescent and reflective paste:

[0017]

[0018] Among the braided ropes: braided ropes of various specifications are manufactured according to customer requirements.

[0019] In the padding fluorescent and reflective pulp: the ultra-high molecular weight polyethyle...

specific Embodiment 2

[0023] A production method of high-strength and high-modulus polyethylene fluorescent reflective ropes, braiding 350-1000D ultra-high molecular weight polyethylene filaments into ropes, padding slurry containing fluorescent and reflective powder, drying after winding, Then bake to make the fluorescent and reflective powder evenly distributed on the surface of the rope. The specific operation includes the following steps: fluorescent and reflective paste configuration → ultra-high molecular weight polyethylene filament → braiding rope → padding fluorescent and reflective paste → winding → drying → baking; where:

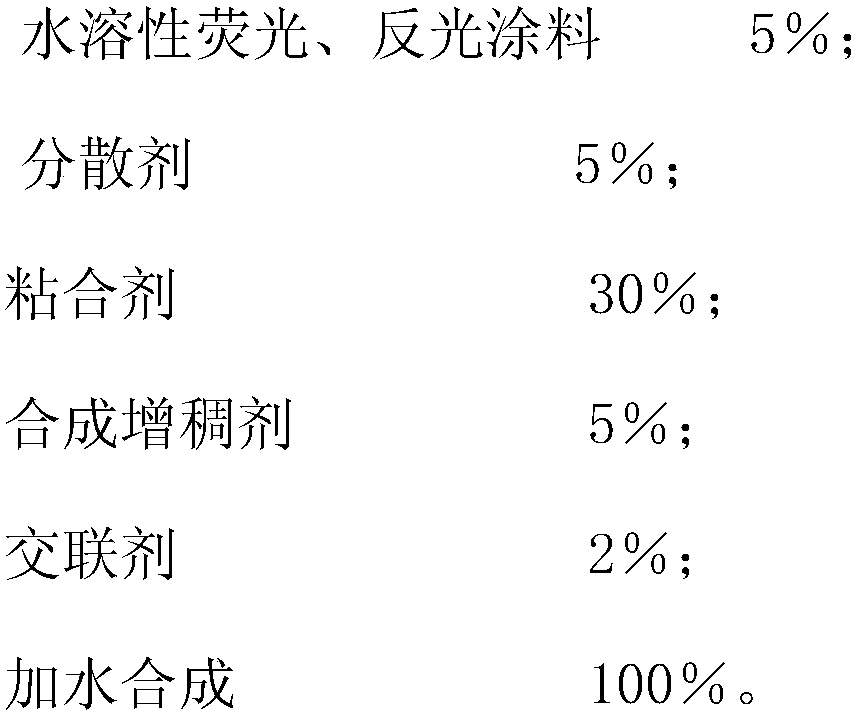

[0024] In the configuration of the fluorescent and reflective paste: the composition of the fluorescent and reflective paste:

[0025]

[0026] Among the braided ropes: braided ropes of various specifications are manufactured according to customer requirements.

[0027] In the padding fluorescent and reflective pulp: the ultra-high molecular weight polyethylene ro...

specific Embodiment 3

[0031] A production method of high-strength and high-modulus polyethylene fluorescent reflective ropes, weaving 600D ultra-high molecular weight polyethylene filaments into ropes, padding slurry containing fluorescent and reflective powder, drying after winding, and then Baking, so that the fluorescent and reflective powder is evenly distributed on the surface of the rope. The specific operation includes the following steps: fluorescent and reflective paste configuration → ultra-high molecular weight polyethylene filament → braiding rope → padding fluorescent and reflective paste → winding → baking dry→baked; where:

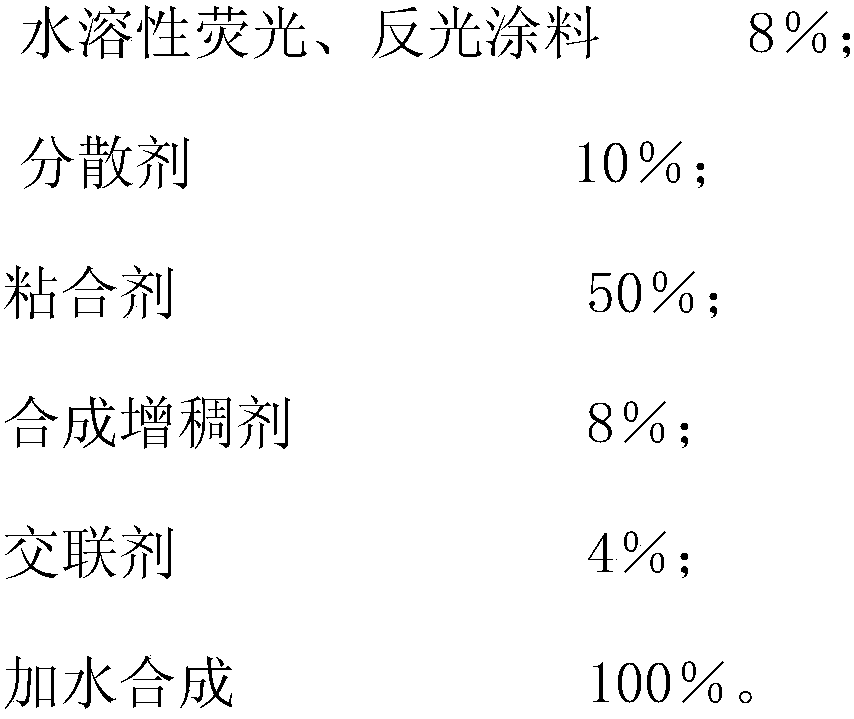

[0032] In the configuration of the fluorescent and reflective paste: the composition of the fluorescent and reflective paste:

[0033]

[0034] Among the braided ropes: braided ropes of various specifications are manufactured according to customer requirements.

[0035] In the padding fluorescent and reflective pulp: the ultra-high molecular weight polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com