High-safety lithium ion battery cathode material and its preparation method

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of lithium-ion battery safety performance degradation, insufficient space, short-circuit of lithium-ion batteries, etc., achieve excellent safety performance and improve conductivity , the effect of reducing the risk of lithium analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The high-safety lithium-ion battery negative electrode material provided by this embodiment is made through the following steps:

[0034] (1) Preparation of Al(OH) 3 sol

[0035] AlCl 3 Pyrolysis at 300°C to obtain basic aluminum chloride, then dissolve basic aluminum chloride with deionized water, filter to obtain the filtrate, the concentration of the filtrate is 0.1mol / L, and the mass percentage concentration of 50% is added to the filtrate polyethylene glycol solution, and then add ammonium chloride to the filtrate, and then react at 90 ° C to obtain Al(OH) 3 Sol; where AlCl 3 The quality of: the quality of polyethylene glycol in polyethylene glycol solution: the quality=1 of ammonium chloride: 0.3: 0.2;

[0036](2) Preparation of graphite / LiAlO 2 Composite powder

[0037] Al(OH) prepared by step (1) 3 Sol mixed with NaOH, LiOH, Al(OH) 3 Al(OH) in sol 3 , and the molar ratio of NaOH and LiOH: Al(OH) 3 :NaOH:LiOH=1:1:1.5; then react at 40°C to prepare LiAlO...

Embodiment 2

[0041] The high-safety lithium-ion battery negative electrode material provided by this embodiment is made through the following steps:

[0042] (1) Preparation of Al(OH) 3 sol

[0043] AlCl 3 Pyrolysis at 200°C to obtain basic aluminum chloride, then dissolve basic aluminum chloride with deionized water, filter to obtain the filtrate, the concentration of the filtrate is 1.0mol / L, and the mass percentage concentration of 20% is added to the filtrate The polyvinyl alcohol solution, and then add ammonium sulfate to the filtrate, and then react at 40 ° C to obtain Al(OH) 3 Sol; where AlCl 3 The quality of: the quality of polyvinyl alcohol in polyvinyl alcohol solution: the quality=1 of ammonium sulfate: 0.1: 0.5;

[0044] (2) Preparation of graphite / LiAlO 2 Composite powder

[0045] Al(OH) prepared by step (1) 3 Sol mixed with NaOH, LiOH, Al(OH) 3 Al(OH) in sol 3 , and the molar ratio of NaOH and LiOH: Al(OH) 3 :NaOH:LiOH=1:1.5:1; then react at 90°C to prepare LiAlO 2...

experiment example

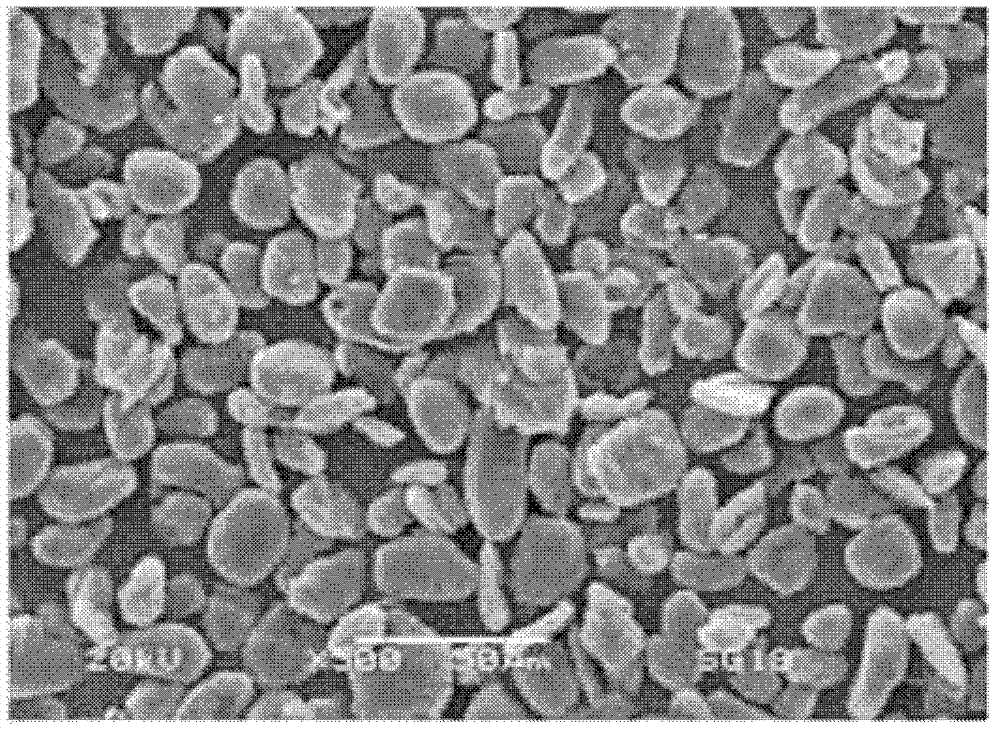

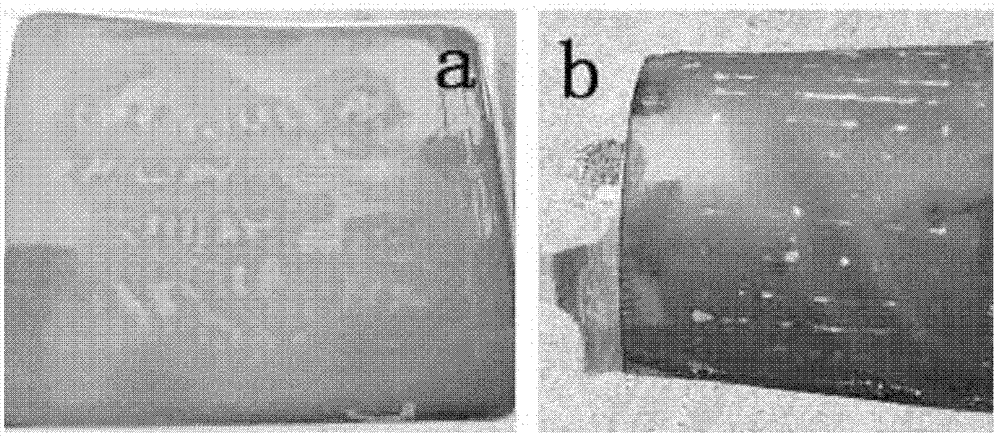

[0049] Graphite / LiAlO prepared with embodiment 1 2 / Carbon nanotubes are used as the negative electrode material, lithium iron phosphate is used as the positive electrode material, and 1.0mol / L LiPF is used 6 / EC+DEC(V EC :V DEC =1:1) (EC: ethylene carbonate, ethylene carbonate; DEC: diethyl carbonate, diethyl carbonate) as the electrolyte, the U.S. Celgard 2300 as the diaphragm, prepared a 40AH lithium-ion battery (battery a), and then The battery is overcharged (due to battery overcharging, lithium ions in the positive electrode material will accumulate rapidly on the surface of the negative electrode, causing lithium to be deposited on the surface of the negative electrode, causing the battery to be unsafe), and then the battery is dissected to observe the lithium ion on the surface of the negative electrode material. And under the same conditions, the battery (battery b) prepared by the normal negative electrode material was overcharged and tested, and then its battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com