Effective thrust and torque calculation method of tunnel boring machine cutterhead on the basis of CSM (Colorado School of Mines) model

A tunnel boring machine and tunnel boring technology, applied in the direction of calculation, geometric CAD, special data processing applications, etc., can solve problems that are not scientific, objective and reliable, can not correctly guide the safety accident hob of tunneling construction, and cannot thrust and torque the cutter head Monitoring provides theoretical basis and other issues to achieve the effect of reducing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

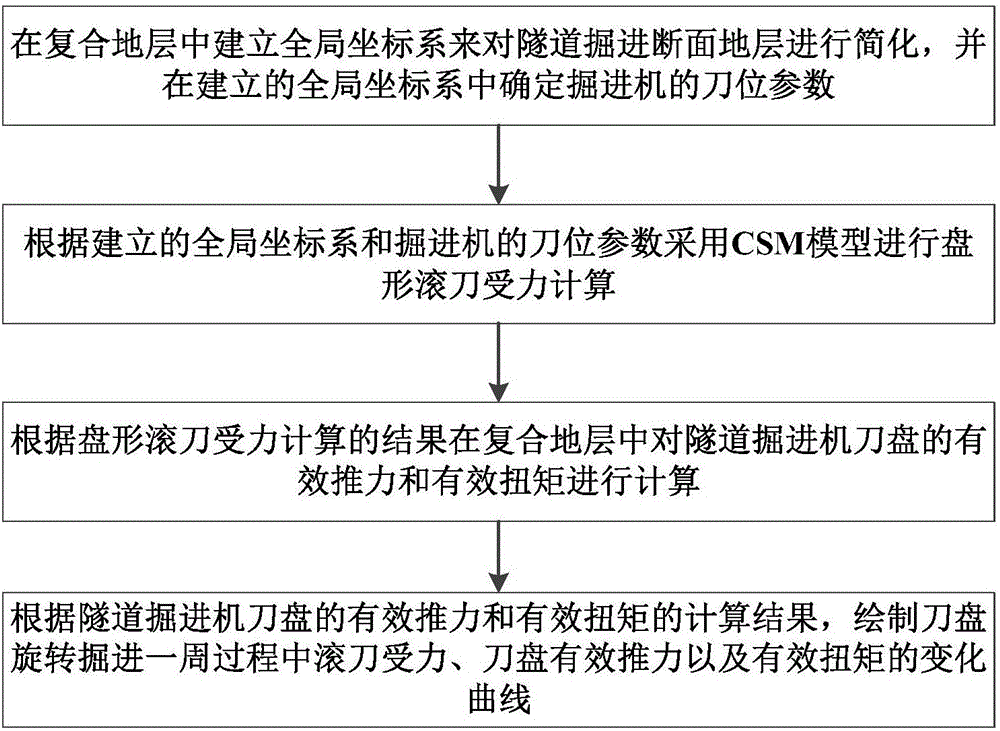

[0069] Aiming at the problem that the existing technology needs to rely on construction experience to estimate the effective thrust and effective torque of the cutterhead of the tunnel boring machine in the construction process of the composite stratum, the present invention proposes a new effective thrust of the cutterhead of the tunnel boring machine based on the CSM model The calculation method of torque and torque can provide a theoretical basis for the reasonable selection and monitoring of tunneling parameters when tunnel boring machines are operating in composite strata, and can better guide tunneling construction. The calculation method specifically includes the following steps:

[0070] 1. Stratum simplification of tunnel excavation section in complex stratum and characterization of cutter position parameters of roadheader.

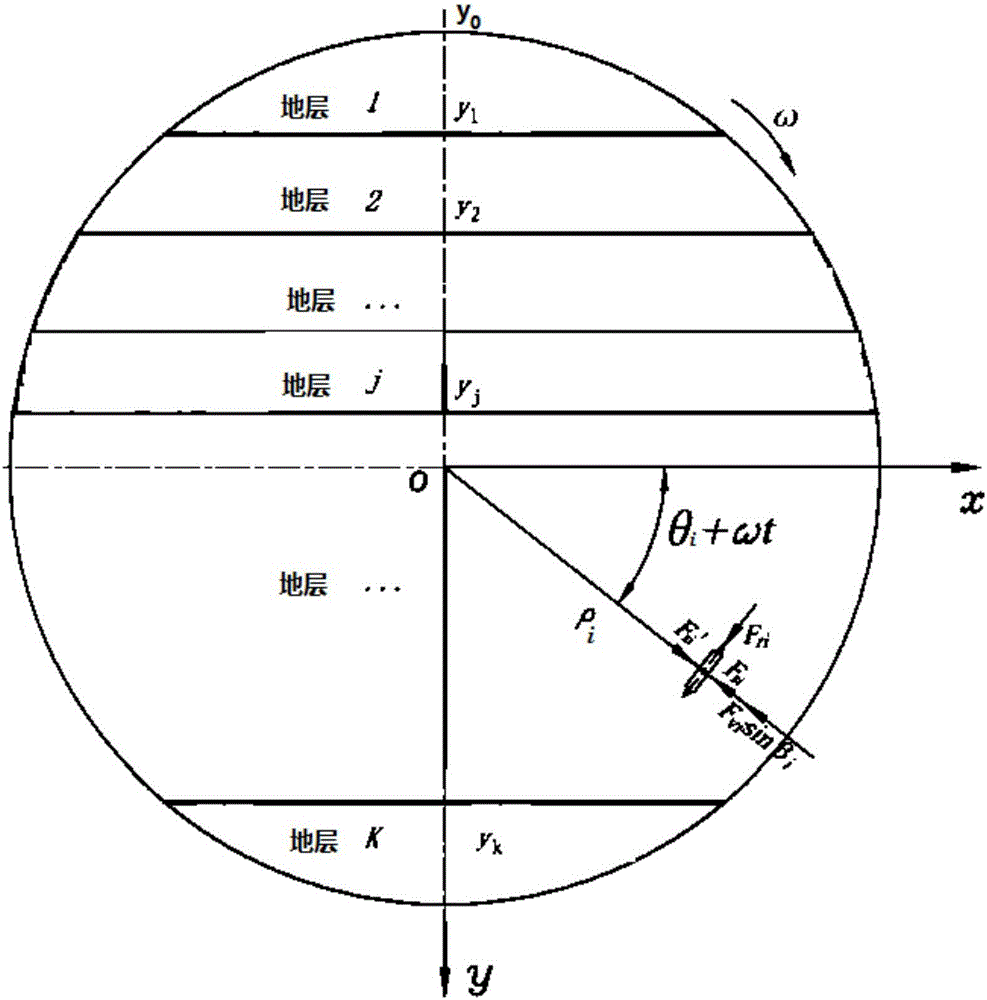

[0071] First, the oxyz global fixed coordinate system is established: take the center of the excavation section as the coordinate origin, the ex...

no. 2 example

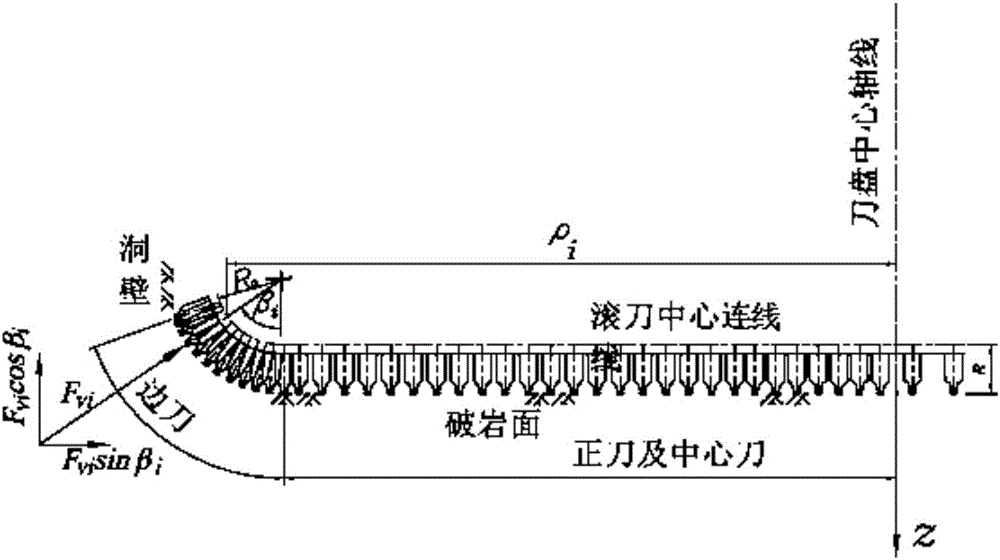

[0100] The composite formation of this embodiment is a typical soft and hard formation, which can be simplified to two layers, that is, K=2, and the formation parameters are as shown in Table 1; the tunnel boring machine of this embodiment is an earth pressure balance type roadheader, and excavation diameter D e 6280mm, a total of 39 17-inch disc hobs are installed on the cutter head, and the radius of the hob is R i =216mm, blade width T i =17.8mm, edge installation radius R 0i =284mm, the cutter position parameters are shown in Table 2; when the roadheader is excavating, the penetration depth of the cutter head per revolution h=5mm / r, and the cutter head speed n=1.2r / min.

[0101] Table 1 Formation parameters

[0102]

[0103] Table 2 tool location parameters

[0104]

[0105]

[0106] Then the specific process of the method for calculating the effective thrust and torque of the tunnel boring machine cutter head in this embodiment is as follows:

[0107] Step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com