High-strength, high-plasticity, low-carbon and medium-manganese TRIP steel and preparation method thereof

A high-plasticity, high-strength technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problems of inverse phase transformation austenite that is difficult to stabilize room temperature, deteriorate material impact toughness, welding performance and fatigue performance, etc., to improve processing The effects of hardening index, high plasticity and simple heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

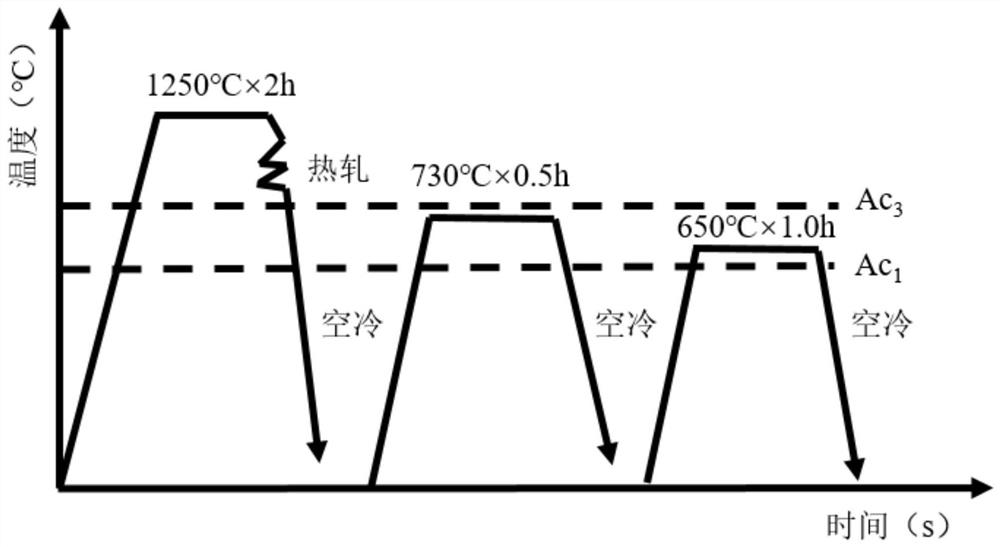

[0049] A preparation method of high-strength and high-plasticity low-carbon medium manganese TRIP steel, comprising the following steps:

[0050] Step 1: Smelting

[0051] According to the mass percentage, the chemical composition of the designed high-strength and high-plasticity low-carbon medium-manganese TRIP steel includes: C: 0.1%, Mn: 3.0%, Si: 0.2%, Al: 0.025%, Ti: 0.015%, P<0.015% , S<0.003%, the balance is Fe and unavoidable impurity elements. Alloy raw materials of various elements are smelted in a vacuum induction melting furnace and cast to obtain cast steel ingots.

[0052] Step 2: Forging

[0053] The as-cast steel ingot is forged into a billet. The as-cast steel ingot is heated to 1200°C-1250°C for 2.0 hours and then free forged. The starting forging temperature is 1230°C and the final forging temperature is greater than 950°C. After forging, it is cooled to room temperature to obtain a forged slab with a thickness of 150mm.

[0054] Step 3: Hot rolling

[...

Embodiment 2

[0073] A kind of preparation method of high-strength high-plasticity low-carbon medium manganese TRIP steel, its process flow chart is shown in figure 1 , including the following steps:

[0074] Step 1: Smelting

[0075] According to the mass percentage, the chemical design composition of the designed medium manganese steel is: C: 0.14%, Mn: 3.8%, Si: 0.4%, Al: 0.02%, Ti: 0.02%, P<0.015%, S<0.003%, and the rest The amount is Fe and unavoidable impurity elements. Alloy raw materials of various elements are smelted in a vacuum induction melting furnace and cast to obtain cast steel ingots.

[0076] Step 2: Forging

[0077] Forge the as-cast steel ingot into a billet, then heat it to 1200°C-1250°C for 2.0 hours and then carry out free forging. The starting forging temperature is 1230°C, and the final forging temperature is greater than 950°C. After forging, cool to room temperature to obtain a thickness of 150mm. forged slabs.

[0078] Step 3: Hot rolling

[0079] Place the...

Embodiment 3

[0097] A preparation method of high-strength and high-plasticity low-carbon medium manganese TRIP steel mainly comprises the following steps:

[0098] Step 1: Smelting

[0099] A high-strength, high-plasticity low-carbon medium-manganese TRIP steel, the chemical composition of which is: C: 0.08%, Mn: 3.1%, Si: 0.3%, Al: 0.04%, Ti: 0.015%, P<0.015% , S<0.003%, the balance is Fe and unavoidable impurity elements.

[0100] According to the above alloy composition, the raw materials are smelted in a vacuum induction melting furnace and cast to obtain cast steel ingots.

[0101] Step 2: Forging

[0102] Forge the as-cast steel ingot into a billet, heat the billet at 1200°C-1250°C for 2.0h, and then perform free forging. 150mm forged slab.

[0103] Step 3: Hot rolling

[0104] Place the forged slab in the RX3-90-12 high-temperature heating furnace under a nitrogen atmosphere, heat it to 1200°C and keep it for 2.0h to ensure the homogenization of the alloy elements of the cast s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com